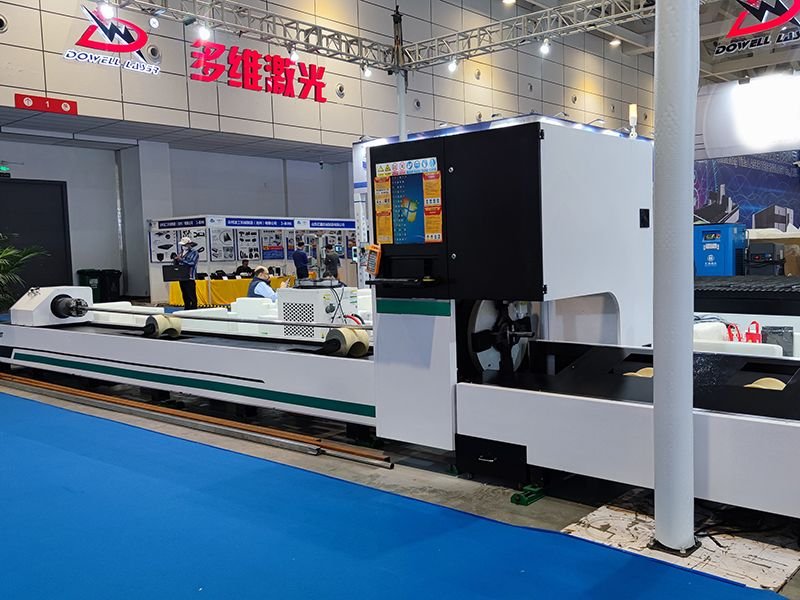

cheapest CNC laser tube cutting machine for sale

- Brand: DOWELL LASER

- Size: 6m 9m 12m 24m

- Power:1000w 1500w 2000w 3000w

- Customizable, OEM ODM

- Delivery time: 30 working days

- Shipping: sea freight

fiber laser tube cutting machine for sale

DOWELL Laser has 15 years of laser equipment manufacturing experience. We can provide you with metal pipe laser cutting machines to cut round pipes, square pipes, rectangular pipes, channel steel, oval pipes, with power 1000w 1500w 2000w 3000w 4000w 6kw for you to choose from.

By type

automatic tube laser cutting machine for sale

metal tube laser cutting machine for sale

plate and tube fiber laser cutting machine for sale

By power

1000w 1500w 2000w fiber laser cutting machine tube

3000w 4kw 6kw fiber laser cutting machine tube

8000w Heavy duty tube laser cutter

Laser cutting metal tube video

Three-chuck pipe laser cutting equipment

1000w CNC Tube Laser Cutting Machine Cutting Round and Square Tubes

How metal laser pipe cutting machine works

how much is laser tube cutting machine price

The price of a CNC laser metal cutting machine can vary depending on the size, power, and features of the machine. Generally, the price for a basic entry-level CNC laser metal cutting machine can start at around $15,000 to $30,000. However, more advanced and larger machines can cost upwards of $100,000 or more. It is recommended to contact manufacturers or suppliers directly to get the most accurate pricing information.

What material is laser tube cutting machine suitable for?

A laser tube cutting machine is suitable for a variety of materials, including metal tubes, pipes, profiles, and beams. Some common materials that a laser tube cutting machine can be used for include:

1. Mild steel

2. Stainless steel

3. Aluminum

4. Copper

5. Brass

6. Titanium

7. Inconel

8. Hastelloy

These materials can be cut with precision and efficiency using a laser tube cutting machine, making it a versatile tool for various industries such as automotive, aerospace, construction, and manufacturing.

Laser cutting tube/pipe applications

furniture manufacturing

Pipe processing

When it comes to pipe processing, advanced technologies like laser cutting play a crucial role in ensuring accurate and clean cuts. Laser cutting offers high precision, allowing for intricate designs while maintaining the structural integrity of the pipes. This modern technique not only enhances the efficiency of pipe processing but also minimizes material waste, making it a cost-effective solution for industries requiring precision cutting.

Pressure vessel

The precision of laser cutting technology ensures the precise shaping of pressure vessel metal plates and simplifies the welding and splicing process. Using laser technology, manufacturers save material waste and improve the efficiency and quality of pressure vessel production. Save time and also help improve the overall durability and performance of the final product.

construction industry

Laser pipe cutting machines have revolutionized the manufacturing process in the construction industry. With their precise cutting abilities, these machines ensure accuracy and efficiency in producing building components. By utilizing different types of metal pipes, including steel, stainless steel, and aluminum alloy, manufacturers can create a wide range of products like doors, windows, stair handrails, and railings. The versatility of laser pipe cutting machines makes them indispensable in modern construction projects, improving both quality and productivity.

Dowell c steel tube laser cutting machine factories

In today’s highly competitive market, finding reliable tube laser cutting machine manufacturers can be a game changer for companies seeking precision and efficiency.

The services we can provide

Manufacturing plants utilize advanced laser technology to ensure precise cutting of C steel tubes to meet a wide range of industrial needs. By partnering with reputable plants, businesses can enhance their production processes and deliver high-quality products to their customers. Investing in quality laser cutting services can significantly increase productivity and streamline manufacturing operations, resulting in long-term success.

Professional customized needs

With our team of expert designers and developers, rest assured that your wholesale customization needs will be met with utmost precision and attention to detail. Whether it’s adjusting appearance, size, or configuration of unconventional equipment, we pride ourselves on delivering tailored solutions that align perfectly with your requirements. Your business deserves nothing less than top-quality customization services, and we are here to make that a reality.

FAQ

Various tube laser cutting machines for sale come with different specifications depending on the manufacturer and model. Key specifications may include laser power, maximum tube diameter, maximum tube length, cutting speed, and software capabilities.

Cutting capacity, laser power, precision, ease of use, and maintenance costs.

There are various types and brands of tube laser cutting machines available, including models from companies like Trumpf, Amada, Mazak, and Bystronic.

1. Laser Source:

- Type: Fiber vs. CO2. Fiber lasers are generally more expensive due to their superior efficiency, precision, and wider material compatibility.

2. Laser Power:

- Higher wattage lasers can cut thicker materials and offer faster cutting speeds, leading to a higher price tag.

3. Work Area Size:

- A larger working area allows you to process bigger tubes or multiple tubes simultaneously, impacting the cost.

4. Brand and Reputation:

- Established brands with a proven track record of quality and reliable after-sales service tend to command a premium price.

5. Additional Features:

- Automated features like automatic material loading/unloading, fume extraction systems, and nesting software can significantly increase the price.

6. Machine Frame and Components:

- The quality and durability of the machine frame, cutting head, and other mechanical components influence the overall cost.

7. Country of Origin:

- Machines manufactured in countries with lower labor costs might be cheaper, but consider potential quality compromises and after-sales support limitations.

8. Customization:

- Any modifications or bespoke functionalities added to the standard machine configuration will raise the price.

9. Warranty and After-Sales Service:

- A longer warranty and comprehensive after-sales service package, including readily available replacement parts and technical support, will affect the price.

- Wear protective gear to avoid skin contact with the laser.

- Follow the operating procedures and check the machine regularly.

- Ensure the safety of materials and the environment, and configure fire protection facilities.

- Do not operate by non-professionals, and wait for cooling before cleaning after cutting.

Tube laser cutter size and power are directly linked to its cutting ability and performance:

- Power:

- Higher Power: Cuts thicker materials and offers faster cutting speeds for thinner materials.

- Lower Power: Limited to thinner materials and slower cutting speeds.

- Size:

- Larger Work Area: Handles bigger tubes or processes multiple tubes simultaneously.

- Smaller Work Area: Limited to smaller tubes or single-tube processing.

Think of it like this:

- A powerful engine in a car allows for higher speeds.

- A larger car can fit more passengers or cargo.