china CNC 6000w fiber laser cutting machine

- Single platform or fully enclosed appearance optional

- 2.5m×6m, 2.5m×8m cutting area

- Maximum cutting thickness 30mm CS, 16mm SS

- OEM ODM

- Price:$20013.52- $51068.99

Introduction

The 6000W CNC fiber laser cutter is a high-power, large-format metal cutting solution that can handle a wide range of materials. Compared with the 1000w 1500w 2000w 3000w, the cutting accuracy is higher and the speed is faster.

These machines are commonly used in industries such as automotive, aerospace, electronics and manufacturing to cut sheet metal, pipes, tubes and other components with high precision.

Laser Cutting type

6000w Single platform Open fiber laser cutting equipment

Fully enclosed laser cutting machine with exchange table

6kw Plate tube fiber laser cutting equipment

6KW Laser Cutting video

customized 6000w fiber laser cutting machine

6000w fiber laser cutting cutting 20mm carbon steel

Features

Technical Parameters

- Brand: Dowell Laser

- Laser power: 6000W, with options up to 8000W available

- Laser Wavelength:1080nm

- Working width (mm):3015/4025/6025/8025/12025

- X/Y axis positioning accuracy (mm/m) ±0.05

- X/Y axis repeat positioning accuracy (mm): ±0.02

- Cooling mode :Water cooling and protection system

- Graphic Format: DXF/PLT/AI/LXD/GBX/NC code

- Positioning accuracy: ±0.02mm/m

- Cutting speed: Up to 40m/min

- Acceleration: Up to 1.5G

- Electrical power: 380V 50/60Hz

- Production place: China

- Customizable super large format

- Auxiliary Gas for Cutting:Oxygen, Nitrogen, Compressed Air

- Compatible Software :AutoCAD, CorelDraw, etc.

Configuration

Fiber laser: MAX, IPG, RAYCUT

The cutting head can be swiveled

Fiber laser cutting machine bed, size can be customized

Aluminum beam

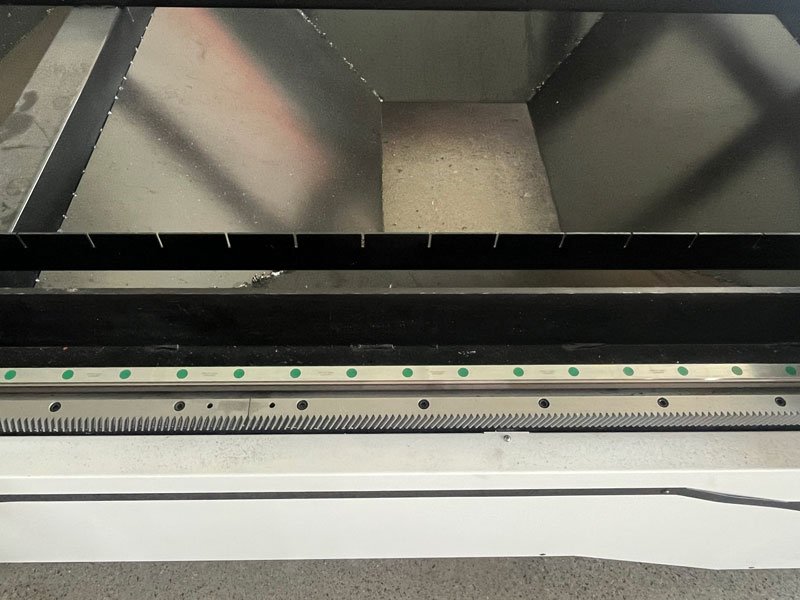

guide

Fiber laser cutting machine bed, size can be customized

cutting products

High-power laser cutting machine is suitable for cutting, hollowing and drilling various metal plates and pipes. It is especially suitable for cutting stainless steel plates, carbon steel plates, galvanized plates, thin aluminum plates, thin copper plates, thin gold plates, thin silver plates and other metal materials with a thickness of less than 40mm.This fiber laser cutter is great for slicing through stainless steel, carbon steel, alloys, even spring steel, copper, aluminum, and more.

application

It’s the go-to for industries like advertising, making electrical cabinets, textile parts, kitchen gear, cars, machinery, elevators, and lots more.

You’ll find it widely used in kitchen gadgets, metal boxes, machinery bits, electronics, fancy lights, signs, car pieces, gym gear, and anything else metal that needs cutting.

How Much is 6000w fiber laser cutting machine price

If you are considering investing in a 6000w fiber laser cutting machine, the 6025-6000w price is $29,675.22 and the 8025-6000w is $31,745.59. The cost of the fiber laser cutting machine may vary depending on the size of the machine, brand reputation, cutting speed, accuracy, and automatic loading/ Uninstall system and other additional features and other factors vary.

If you want to buy an affordable 6000w fiber laser cutting machine, dowell laser is your ideal partner, you can contact us to provide you with customized fiber laser cutting solutions.

FAQ

What factors should I consider when purchasing a 6kW metal fiber laser cutting machine?

If you are considering purchasing a 6000W cnc fiber laser cutting machine, there are a few factors to consider:

Budget: fibre laser cutter can range in price from tens of thousands of dollars to hundreds of thousands of dollars. It is important to determine your budget before you start shopping.

Cutting needs: Consider the types of materials you will be cutting and the thickness of the material. This will help you determine the power and cutting speed you need.

Features: Some fiber laser metal cutting come with additional features, such as automatic loading and unloading systems and dust collection systems. Consider the features that are important to you and your business.

Reputation: Research different manufacturers and read reviews before you make a purchase.

Where can I buy a 6kW fiber optic laser cutter?

6kW fiber optic laser cutter can be purchased from a variety of online and offline retailers. Some popular online retailers include Alibaba, AliExpress, and eBay. You can also find 6kW fiber laser cutter for metal from local industrial equipment dealers.

What is the maintenance schedule for a fiber laser cutting machine 6kw?

The maintenance schedule for a fiber laser cutting machine 6kw will vary depending on the manufacturer. However, most manufacturers recommend that you perform regular maintenance, such as cleaning the laser head and checking the alignment of the laser beam, every 500-1000 hours of operation.

What are the safety precautions for operating a 6kW fiber laser cutting machine?

6kW cnc fiber laser cutting machines are powerful machines that can be dangerous if not operated safely. Some of the safety precautions that you should take when operating a 6kW fiber laser cutting machine include:

- Always wear safety glasses and protective clothing.

- Make sure that the area around the laser cutter is clear of debris and flammable materials.

- Never look directly into the laser beam.

- Do not operate the laser cutter if it is damaged or malfunctioning.

Disadvantages of using fiber laser cutting machine

Disadvantages of fiber laser cutting machines are their higher initial cost, limited cutting depth, sensitivity to highly reflective materials, higher energy consumption, and ongoing maintenance requirements compared to other laser cutting technologies. However, the search results indicate that the advantages of fiber lasers generally outweigh these drawbacks.

Limitations in cutting thicknessachines in terms of cutting thickness

Key limitations of fiber laser cutting machines in terms of cutting thickness are the practical limits based on laser power, material type, beam focus, assist gas penetration, and machine design constraints. These factors restrict the maximum thickness that can be effectively cut, especially for non-metallic and highly reflective materials.