China Best Metal Sheet and Tube Laser Cutting Machine for Sale

- Brand Name:DOWELL LASER

- Power:1000w- 60kw

- CNC or Not:Yes

- Laser type:Fiber laser generator

- Lubrication system:Full-automatic

- Betriebsart: Dauerwelle

- Cutting materials:Stainless Steel Carbon Steel

Beautiful and best way to make your User Interface meaningful

Einführung

Sheet and tube laser cutting machines are versatile tools used for precision cutting of metal sheets and tubes. These machines typically use fiber laser technology for efficient and accurate cutting.

A sheet and tube laser cutting machine is a versatile piece of equipment that combines the capabilities of both sheet metal and tube cutting in a single machine. This integration offers several advantages, including cost-efficiency, space-saving, and enhanced production flexibility.

Selection Guide

This professional selection manual is specially tailored for metal processing enterprises seeking efficient, cost-effective and versatile cutting equipment, designed to help you easily navigate the selection process and pick the optimal sheet & tube integrated fiber laser cutting machine that perfectly matches your production needs.

Unlike ordinary selection materials, our manual focuses on practicality and marketing value, clearly elaborating on how to select equipment based on your processing scale, material types (including various sheets, round tubes, square tubes, rectangular tubes, etc.), processing precision requirements and budget constraints.

Customer Rating

(234)

(304)

(327)

Common models

DW1530-AC/1540AC/2040AC/2060AC

DW1530-TF/2040-TF/2560-TF

DW3015-TF Pro/4020-TF Pro/6020-TF Pro

Plate cutting range

1500mm*3000mm / 1500mm*4000mm / 2000mm*4000mm / 2000mm*6000mm

1500mm*3000mm / 2000mm*4000mm / 2500mm*6000mm

3000mm*1500mm / 4000mm*2000mm / 6000mm*2000mm

Pipe diameter range (mm)

20-φ220 (standard configuration), 10-φ150 (optional configuration)

φ20-φ220 (standard configuration), φ10-φ150 (optional configuration)

The diameter of the circumscribed circle of the cross section is less than 220 mm.

Max. pipe length (mm)

6000mm

External dimensions

7800mm*3300mm*1800mm / 7800mm*3800mm*1800mm / 8100mm*3800mm*1800mm

8600mm*3700mm*2100mm / 11000mm*4200mm*2100mm / 13500mm*4700mm*2100mm

10900mm*3000mm*2050mm/ 13000mm*360mm*2050mm/ 17500mm*3600mm*2050mm

Laserleistung

3000W~6000W~12000W

Max. cutting speed (m/min)

60m/min

100m/min

140m/min

Positioning accuracy

±0.03mm/1000mm

Equipment power

20kw/20kw/23kw/23kw

20kw/23kw/23kw

20kw/23kw/23kw

Total weight

4500kg/5500kg/6000kg/700kg

9000kg/10500kg/12000kg

11500kg/13000kg/15000kg

Power supply

3P 380V/50Hz/60Hz

Working environment

Temperature: 0~45°C Humidity: ≤80% (non-condensing)

Note: It details the core parameters, functional advantages and application scenarios of different models, helping you avoid wrong selections, reduce investment risks and maximize the return on equipment investment. Whether you are a small and medium-sized enterprise looking to expand production capacity or a large manufacturer aiming to upgrade the production line, this selection manual will provide you with professional guidance – from understanding the key indicators of sheet & tube integrated cutting equipment to matching the most suitable model for your business, every link is designed to help you improve processing efficiency, reduce production costs and enhance core competitiveness in the metal cutting industry. With this manual, you can easily select a high-performance, stable and cost-effective sheet & tube integrated fiber laser cutting machine, laying a solid foundation for your efficient and high-quality production.

Paramètres techniques

- Marke: Dowell Laser

- Power: 1000w -60kw

- Arbeitsbreite (mm): 3015/4025/6025/8025/12025

- Maximum speed :120m/min

- Maximum accelerated speed:1.2G

- Reposition accuracy: ±0.02mm/1000mm

- Graphic format supported :AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT

- Anpassbare Designs

- Working environment Temp:0-40℃,humidity:≤80%, No condensation

- Position accuracy: ±0.03mm/1000mm

- Lieu de production : Chine

- Anpassbares Supergroßformat

Video zum Laserschneiden

Benefits of sheet tube laser cutter

- High-speed, high-precision cutting

- Reduced operating costs compared to traditional cutting methods

- Ability to cut complex shapes and intricate details

- Minimal heat damage to surrounding material

- Improved overall quality and efficiency in metal fabrication processes

Merkmale

- Ability to cut both sheet metal and tubes/pipes

- Precise and smooth cutting with minimal burrs

- Suitable for cutting stainless steel, mild steel, carbon steel, alloy steel, galvanized sheet, aluminum, and other metals

- Some models offer dual-use functionality for both sheet and tube cutting

Aufbau

fiber Laser Source

Raycus/Max/IPG, multiple choice Different brands, different laser power are available. The higher power, the thicker cutting thickness.

Professionl fiber laser cutting head

Fiber optic cutting head with Swiss technology, professional QBH fiber optic output interface, high sealing, precise focal length calibration. The cutting gap can be as short as 0.1mm, improving cutting performance and reducing gas consumption

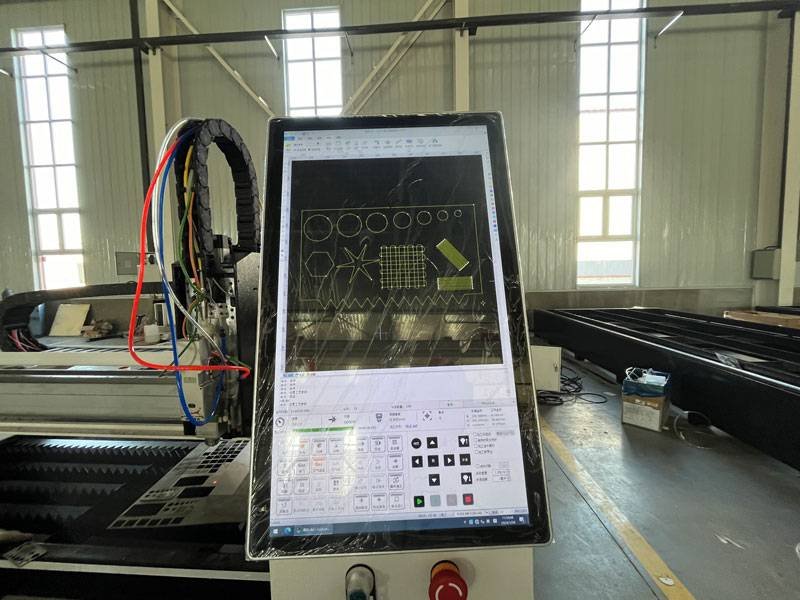

Cypcut Control System

laser cutting machine bed

High stability bed, after high temperature annealing treatment, high effectiveness and strong stability

Servo motor

S&A Water Chiller

With excellent quality and leading research retrength, S&A has become a leading enterprise in the China industrial refrigeration industry.

How Much is A Sheet and tube laser cutting machine price

The price of a sheet and tube laser cutting machine can vary widely depending on several factors:

- Machine size and capacity: Larger machines with higher power outputs will generally cost more.

- Lasertyp: Fiber lasers are typically more expensive than CO2 lasers.

- Automation level: Machines with advanced automation features will command a higher price.

- Marke und Ruf: Well-established brands often have premium pricing.

- Additional features: Options like automatic loading and unloading systems, software packages, and maintenance contracts can increase the cost.

DOWELL plate tube laser cutting machine factory manufacturer

Dowell Laser, a prominent name in the laser cutting machine industry, boasts a rich 15-year history of manufacturing excellence in China. With a strong commitment to OEM and ODM services, Dowell Laser is at the forefront of technological advancements, incorporating cutting-edge CNC systems, laser sources, and transmission systems into its products.

FAQ

How to choose a suitable plate and tube laser cutting machine?

When choosing, you need to consider factors such as the thickness of the cutting material, cutting accuracy requirements, cutting speed, floor space, budget, etc.

What are the maintenance of the tube and plate laser cutting machine?

Regularly clean the cutting head, replace consumables, check the cooling system, lubricate the transmission parts, etc.

How do dual-use sheet and tube laser cutting machines perform compared to specialized machines

| Aspekt | Dual-use Sheet and Tube Laser Cutting Machines |

|---|---|

| Vorteile | • Versatility (cuts both sheet and tube) • Space-efficient • Cost-effective • Streamlined workflow |

| Nachteile | • Potential power limitations • More complex mechanics • Material handling challenges • Possible speed trade-offs • Potential size restrictions |

| Performance | • Comparable accuracy to specialized machines • High flexibility for varied jobs • Good software integration |

| Best suited for | Shops requiring versatility in cutting both sheet and tube |

What types of shapes can tube lasers cut?

Tube lasers can cut round, square, rectangular, and oval tubes, as well as angles, channels, beams, and custom extrusions

Advantages of the tube plate integrated laser cutting machine compared with traditional cutting methods?

Compared with traditional cutting methods, laser cutting has higher efficiency, precision and flexibility, can process more complex parts, and reduces labor costs and material waste.

What are common problems encountered with tube laser cutting machines?

Common issues include rough cuts, beam instability, nozzle clogging, and material handling problems. Regular maintenance and proper machine settings can help mitigate these issues

How does the cutting process work in a tube laser cutting machine?

The machine uses a high-powered laser beam focused on the tube’s surface, melting or vaporizing the material to create precise cuts. The process is guided by a computer-controlled motion system

What after-sales services should be considered when purchasing a plate and tube laser cutting machine?

The supplier’s after-sales service capabilities should be considered, including installation and commissioning, training, maintenance, spare parts supply, etc.