China Professional Metal Laser Forming EquipmentManufacturer Since 2010

No best, Only better.

Dowell Laser will create greater value for you!

Excellent Employees of the Production Team

Professional R&D Technicians Staff

International Certifications and Honor Awards

H-beam I-beam Structural Steel Laser Processing Center

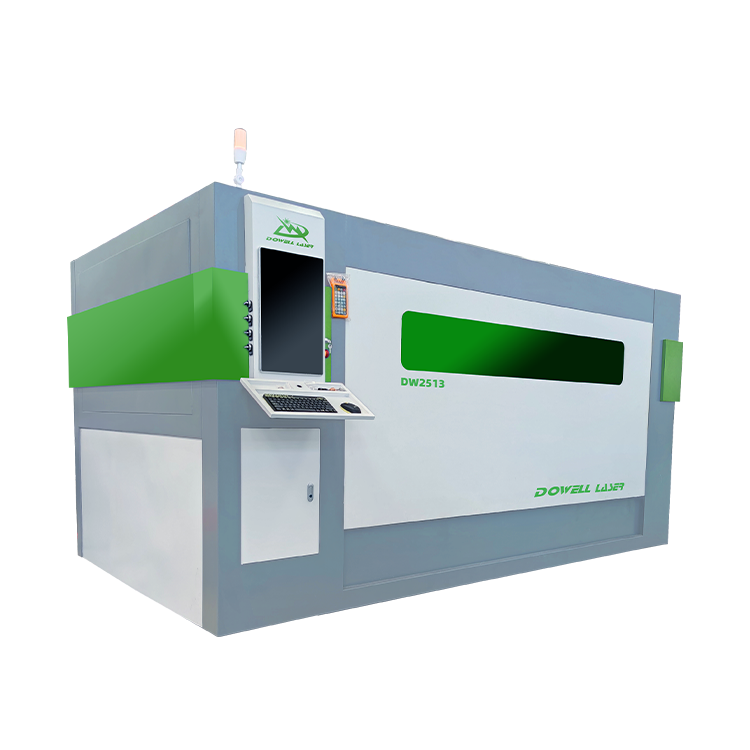

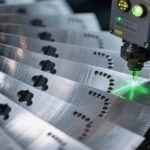

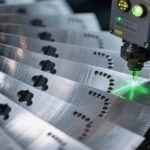

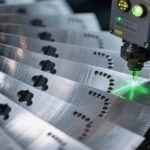

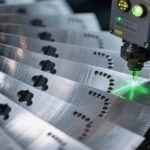

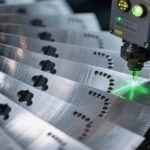

High-speed High-power Laser Cutting Machine

Automatic Loading and Unloading Laser Pipe Cutting Machine

Pick the Most Suitable

Laser Welding/Cleaning Machine

Still troubled by the difficulty in recruiting welders and unstable welding quality? The low efficiency and damage caused by traditional cleaning? Dowell Laser will bring you industrial grade portable laser equipment, free on-site demonstrations, and customized solutions

Industrial Handheld Laser Welding Machine

Alternative Argon Arc Welding

No Deformable Industrial Welding

Handheld design suitable for complex workpieces, portable body easily handles high-altitude and narrow space operations, no need for large fixtures, single person operation, no need for polishing after welding, helping enterprises improve product accuracy.

Know More

Portable Handheld Laser Cleaning Machine

No damaging rust removal

Efficient Industrial Cleaning

Lightweight body suitable for complex scenarios, flexible handheld operation without dead corners, zero damage protection for workpiece surface; Portable and easy to operate, it can replace traditional processes such as sandblasting and acid washing, reducing labor and consumables costs.

Know More

Handheld Laser Welding + Cleaning Machine

rust removal after welding at one time

Integrated design of welding and cleaning

Say goodbye to the trouble of rust removal after welding! This 2-in-1 device features precise welding (smooth and secure weld seams) followed by efficient cleaning (removal of oxide layer/oil stains), completing two steps in one process, doubling production efficiency and reducing consumable waste.

Know More

3-in-1 Handheld Laser Cutting Welding Cleaning Machine

One machine can handle multiple processes

All-in-one Laser Equipment

No need to purchase cutting, welding, and cleaning equipment at the same time, one machine can replace three machine; A kitchen appliance factory uses it to achieve a "cutting-welding-removing welding spot" assembly line operation, reducing labor costs by 35%~40%.

Know More

Lightweight Air-cooled Laser Welding Machine

Say goodbye to bulky water tanks

Integration of welding and air cooling

The air-cooled design eliminates the need for a water cooling device, resulting in a compact body that doesn't take up much space. It also saves on electricity and consumables, and is compatible with various metal materials. It can be used for mass production and emergency maintenance.

Know More

Portable Handheld Laser Cleaning Machine

No damaging rust removal

Efficient Industrial Cleaning

Lightweight body suitable for complex scenarios, flexible handheld operation without dead corners, zero damage protection for workpiece surface; Portable and easy to operate, it can replace traditional processes such as sandblasting and acid washing, reducing labor and consumables costs.

Know More

Automatic Laser Welding Robot

24-hour Continuous operation

Multi-axis Linkage

Say goodbye to the problem of low efficiency and poor precision in manual welding! Customizable welding path, matched with specialized fixtures to adapt to different workpieces, 6-axis/8-axis linkage to adapt to complex workpieces.

Know More

3-in-1 Handheld Laser Cutting Welding Cleaning Machine

One machine can handle multiple processes

All-in-one Laser Equipment

No need to purchase cutting, welding, and cleaning equipment at the same time, one machine can replace three machine; A kitchen appliance factory uses it to achieve a "cutting-welding-removing welding spot" assembly line operation, reducing labor costs by 35%~40%.

Know More

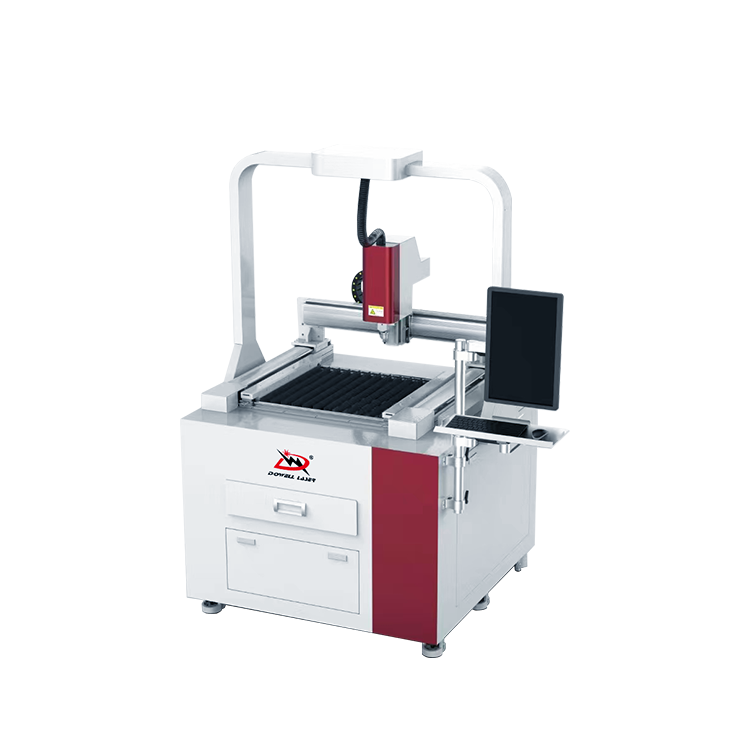

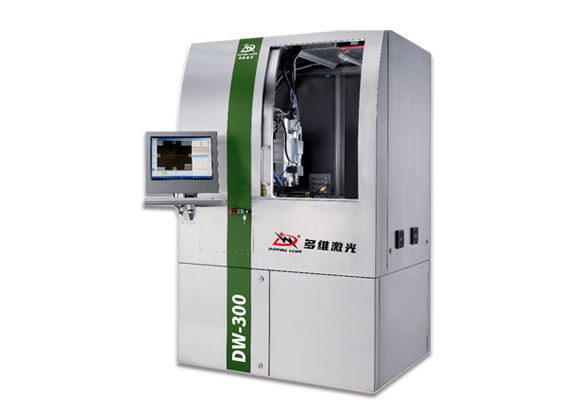

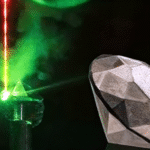

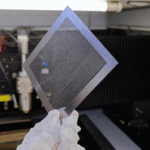

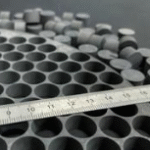

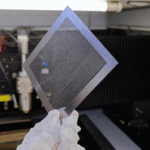

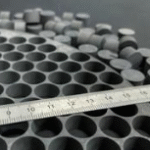

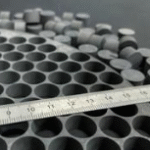

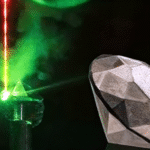

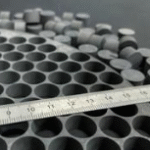

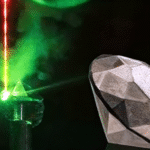

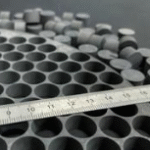

3 Axial Water-conducting Laser Cutting Machine

Combining the dual advantages of “high-pressure water jet light guidance” and “laser energy focusing,” with “zero thermal impact, zero mechanical stress, and ultra-precision cutting” as the core, we provide high-precision processing solutions across materials for industries such as 3C electronics, optical instruments, aerospace, and jewelry, redefining the cutting standards for difficult-to-machine materials, it provides core technical support for the precision and lightweight development of high-end manufacturing fields.

5 Axis Water Jet Laser Cutting Machine

Multi Axis Water Guided Laser Cutting Machine

When traditional cutting equipment is constrained in the face of complex curved surfaces and irregular structures, multi axis water guided laser cutting machines open up the three-dimensional era of precision machining with the “multidimensional collaboration of laser and water”. It achieving full scene coverage from planar cutting to 3D conformal machining, providing “no dead corners” precision solutions for high-end manufacturing fields such as aerospace, precision molds, and medical implants.

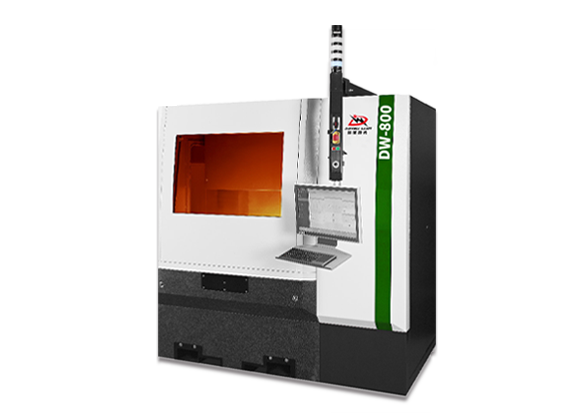

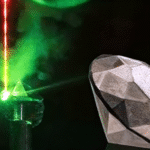

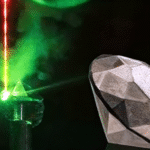

Water Jet Guided Laser Machining Center Define Machining Accuracy

When traditional cutting techniques are repeatedly limited in the face of high hardness, high brittleness, or heat sensitive materials, water guided laser cutting redefines the boundaries of precision machining with the innovative principle of “softness with rigidity”. The Dowell Laser water guided laser cutting system couples a high-energy laser beam with a high-speed flowing small water beam, using water as the “guiding medium” and “cooling carrier” to achieve stress free and high-precision cutting of various difficult materials, providing disruptive solutions for high-end manufacturing fields such as aerospace, semiconductors, and precision instruments.

Nanometer Level Machining Solution

nanometer level positioning and micrometer level cutting

Ultra-precision

Faserlaserschneidemaschine

In fields such as precision electronics, medical devices, aerospace, and automotive precision components that require strict machining accuracy, traditional cutting equipment (such as wire cutting and water cutting) often faces problems such as insufficient accuracy, low efficiency, and poor material adaptability. The high-precision laser cutting machine, with “nanometer level positioning, micrometer level cutting, and intelligent control” as its core, provides ultra precision machining solutions for metal materials (stainless steel, aluminum alloy, titanium alloy, copper, etc.) with a thickness of 0.05-30mm, achieving high-precision output from complex graphic cutting to fine structure composition, and providing core processing capabilities for the production of high value-added products.

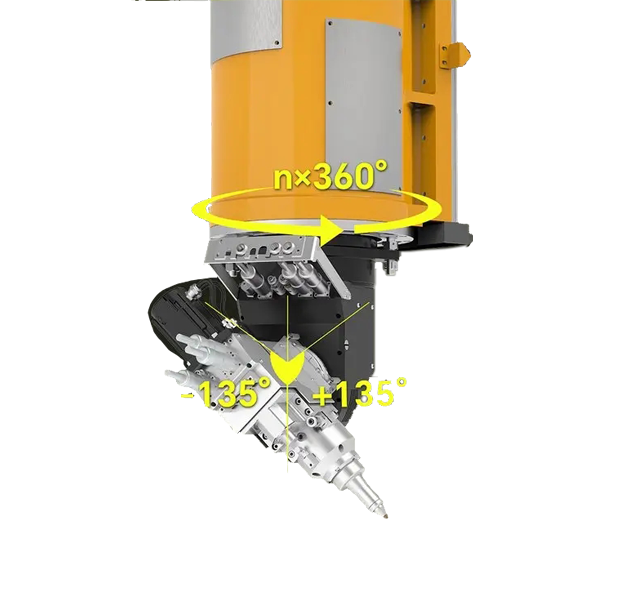

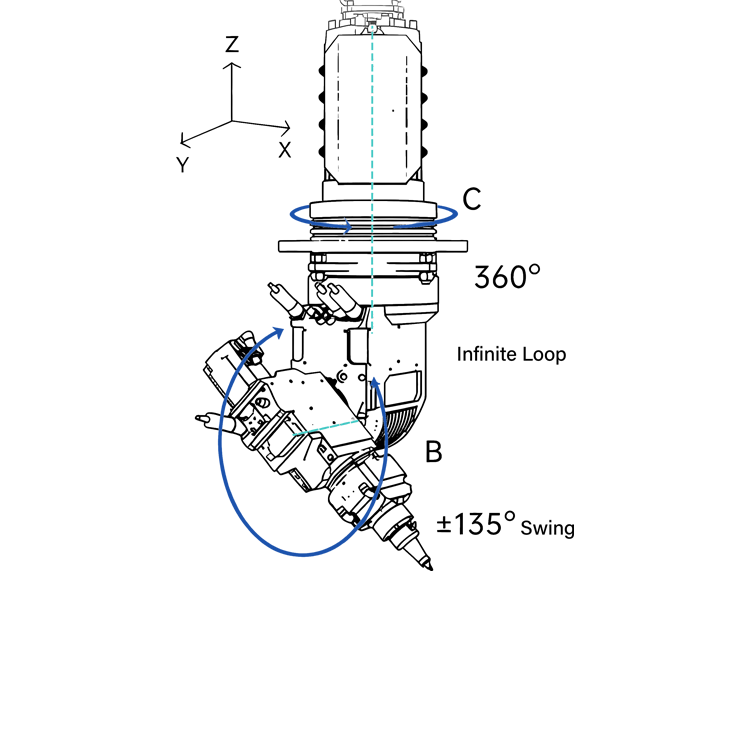

3D-5-Achsen-Faserlaser-Schneidemaschine Flexible Production Adaptation

The 3D 5-axis laser cutting machine breaks through the limitations of traditional cutting with its five axis linkage and three-dimensional spatial operation capabilities. The laser beam can be precisely focused at any angle, suitable for processing curved surfaces, irregular parts, and complex three-dimensional structures, without the need for secondary clamping, greatly improving production efficiency. The heat affected zone is extremely small, the incision is smooth without burrs, and the accuracy is controlled within ± 0.02mm. It is compatible with various materials such as metals and composite materials. Widely used in aerospace, automotive manufacturing, mold processing and other fields, providing efficient and accurate integrated solutions for complex component manufacturing.

New Energy

Heating,Ventilating and Air Conditioning

Lithium Batteries & Heat Exchangers Laser Welding Automation Solution

In response to industry pain points such as “virtual connection of multi-layer stacking of electrode ears” and “leakage of poor shell sealing” in lithium battery welding, the system innovatively integrates real-time melt pool monitoring and AI adaptive adjustment technology: by capturing changes in welding temperature field through high-speed infrared cameras, the algorithm responds in milliseconds to adjust laser power and welding speed, ensuring stable metallurgical bonding under conditions such as electrode ear oxide layer and shell thickness deviation, and improving weld strength by more than 20%.

From civil air conditioning heat exchangers to industrial waste heat recovery equipment, from new energy vehicle thermal management systems to aerospace special radiators, this system can flexibly adapt to the production needs of heat exchange plates of different specifications and materials, helping enterprises improve production efficiency by more than 30%, reduce maintenance costs in the later stage, and provide solid technical support for efficient, energy-saving, and reliable heat exchange equipment manufacturing.

Strong strength, advanced technology, wide application.

Portable Optical Fiber Laser Obstacle Remover

- Power line kites, tree barriers, bird nests? Laser obstacle clearing machine ground operation, efficient clearing and power supply protection.

- Is it difficult to clear obstacles in mountainous areas and cross river routes? The laser obstacle clearing device operates 24/7 and can easily handle complex working conditions.

- Municipal high-altitude tree barriers and ice formation in ski resorts? The laser obstacle clearing device has non-contact processing, ensuring safety and security.

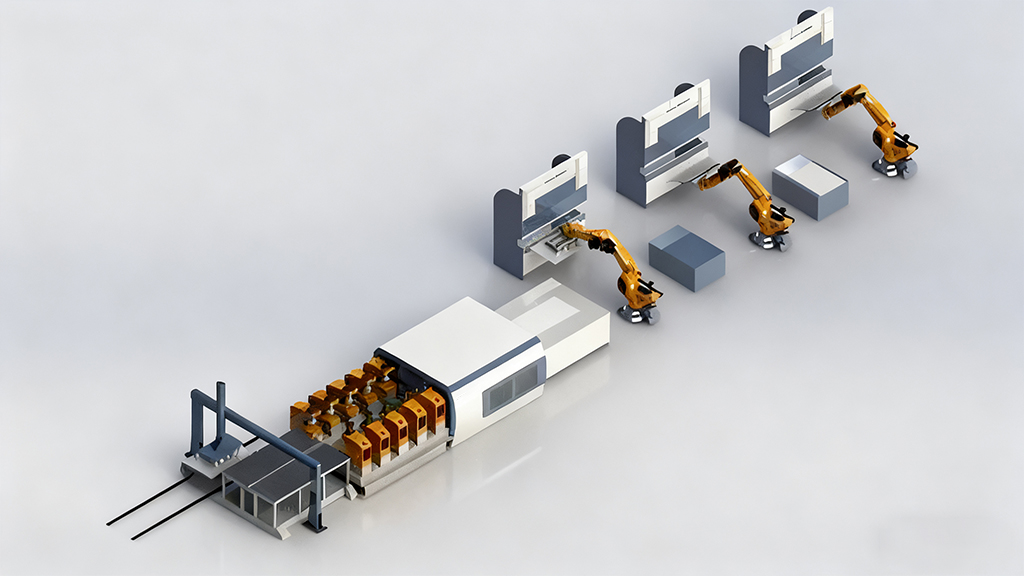

Decoiling, Leveling, Feeding, Laser Cutting, Loading, Bending, Laser Welding and Finished Product Stacking

Intelligent & Digital sheet-metal Processing Factory Solution

Dowell Laser can customize automation solutions based on customers’ actual production needs, covering multiple automated production lines. It combines intelligent equipment and people to achieve flexible and efficient production, shorten the production cycle of enterprise orders, and help the transformation and upgrading of the manufacturing industry, realizing intelligent manufacturing in the era of Industry 4.0.

Small space? Low production capacity? No problem, Dowell Laser has solutions for all of them.

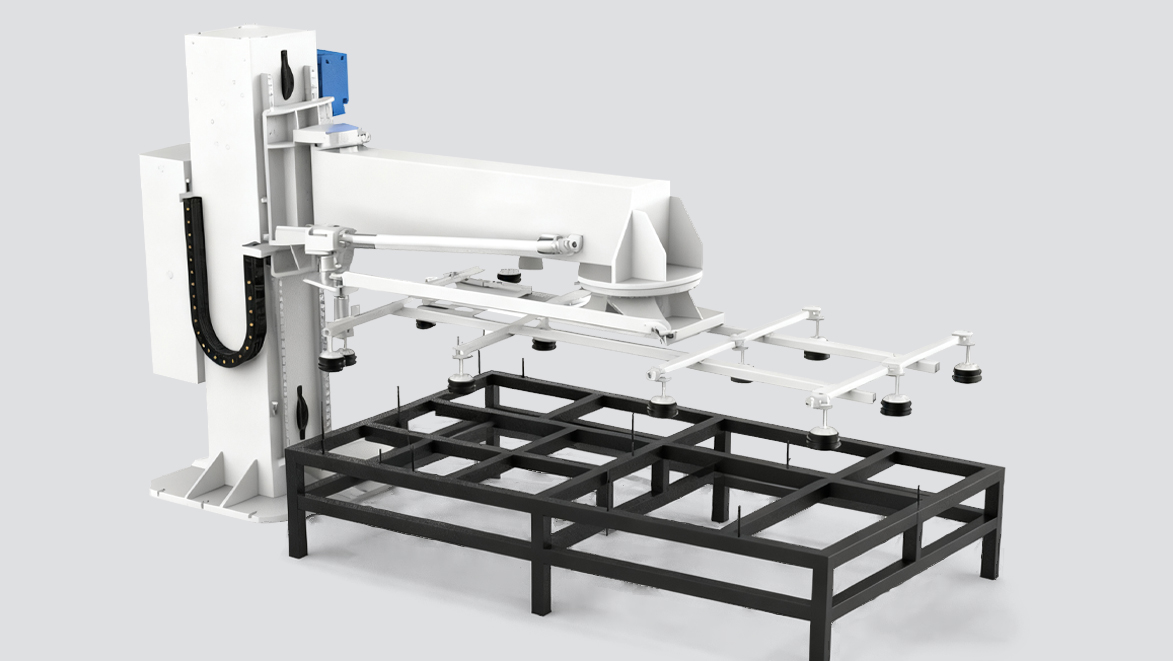

Column Robot with Manual Sheet Material Library

The column robot with manual sheet metal warehouse focuses on “high cost-effectiveness, small space adaptation, and flexible operation”, integrating the precise handling ability of the column robot with the convenient material preparation function of the manual sheet metal warehouse, providing a “semi automated” upgrade path for small and medium-sized enterprises, and achieving orderly and efficient processing flow while reducing manual labor intensity.

Guide Rail Robot with Manual Sheet Material Library

The guide rail robot is multi-station robot developed according to customer needs. It is suitable for loading and unloading of laser cutting machines and plates. The robot system has high efficiency, high stability, simple structure, and more convenient maintenance, which can meet the production of different types of products. For users, it can quickly adjust product structure, expand production capacity, and greatly reduce the labor intensity of industrial workers.

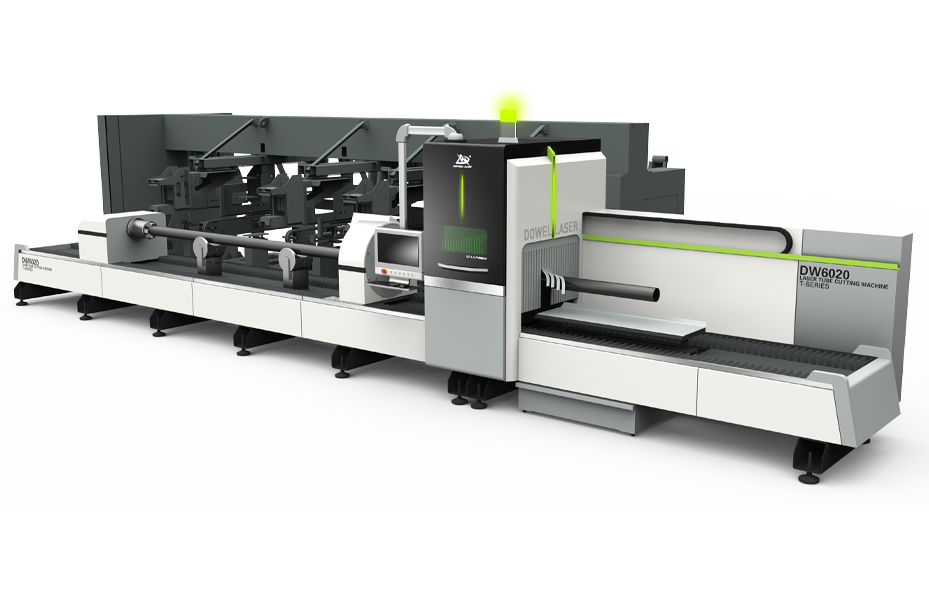

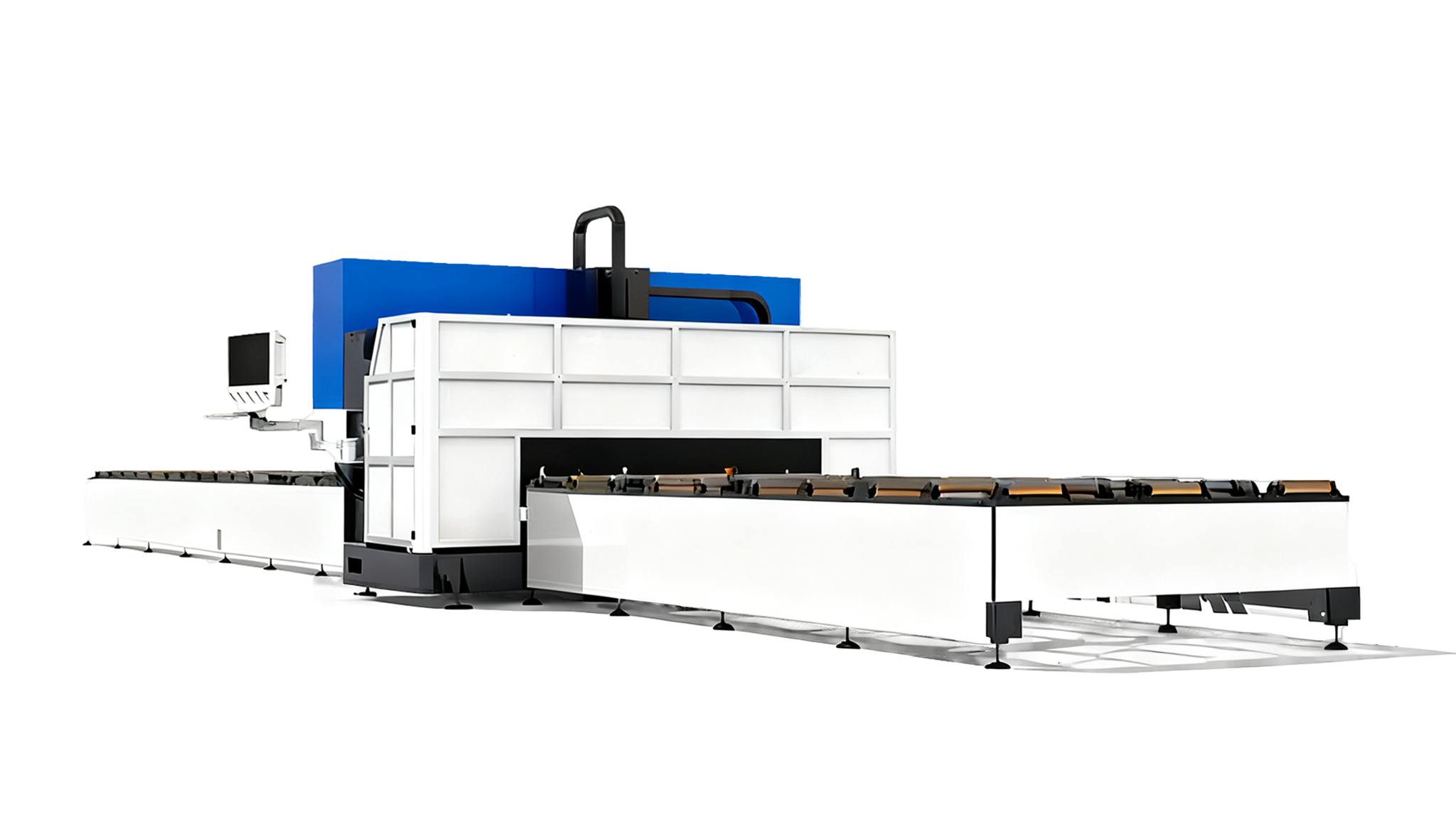

Auto loading and unloading laser pipe cutting machine

With the core advantages of “intelligent nesting saves materials, automatic loading and unloading efficiency, and high-precision cutting ensures quality”, it is specially designed for metal pipes such as round pipes, square pipes, rectangular pipes, and irregular pipes (diameter 10-200mm, length 1-6m), realizing the full process automation from pipe loading, intelligent nesting, laser cutting to finished product unloading, providing efficient, accurate, and low-cost pipe processing solutions.

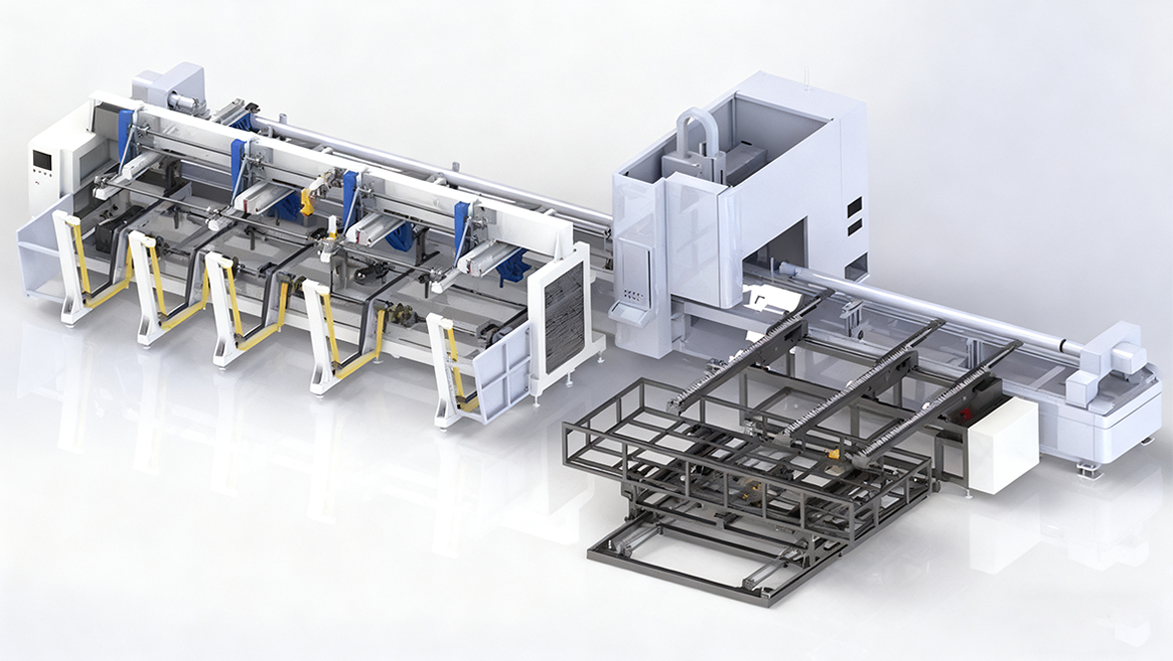

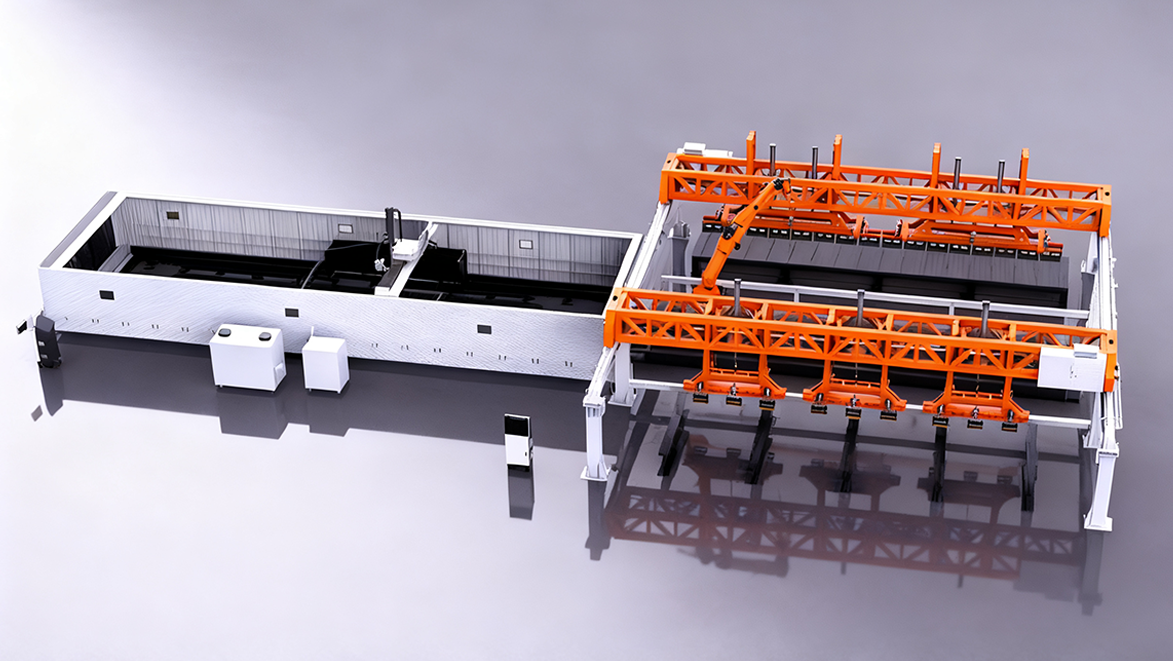

Steel Structure Fiber Laser Processing Center

In industries such as steel structures, bridge construction, building curtain walls, and lifting machinery, the processing of H-beams, I-beams, channel steels, angle steels, and other types of steel has long faced traditional technological bottlenecks: drilling relies on insufficient precision of rocker drills, cutting relies on flame/plasma to cause thermal deformation, manual loading and unloading labor intensity is high, and the efficiency of multi process connection is low. The steel structure steel laser processing center (with automatic loading and unloading function) will be your first choose.

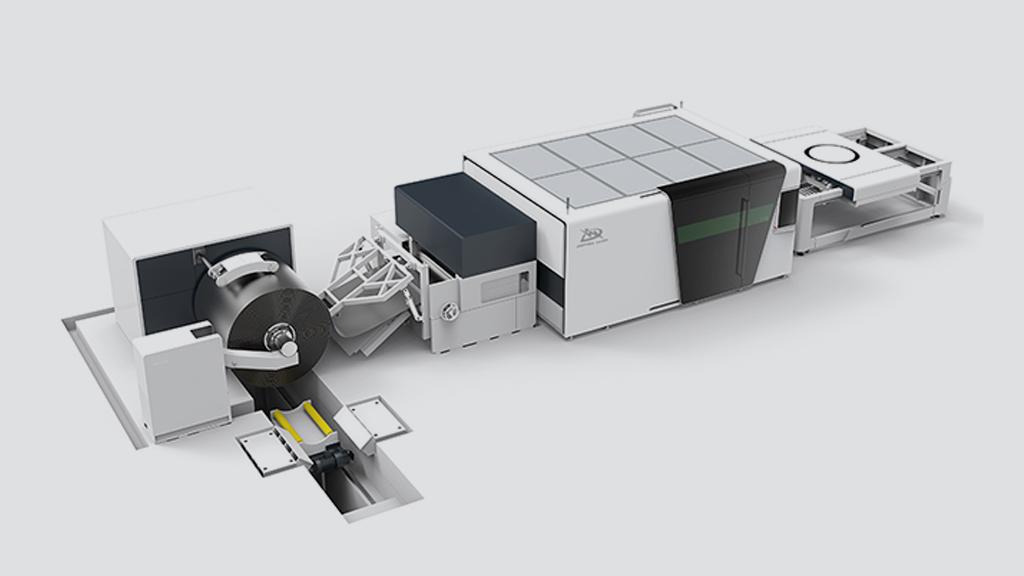

Intelligent laser cutting flexible production line

Through the collaborative linkage between laser cutting equipment and automated conveying, sorting, and storage systems, combined with a digital management platform, metal workpieces of different materials, specifications, and shapes can be easily switched, efficiently processed, and flexibly circulated, providing core support for enterprises to break through the bottleneck of multi variety production and enhance comprehensive competitiveness.

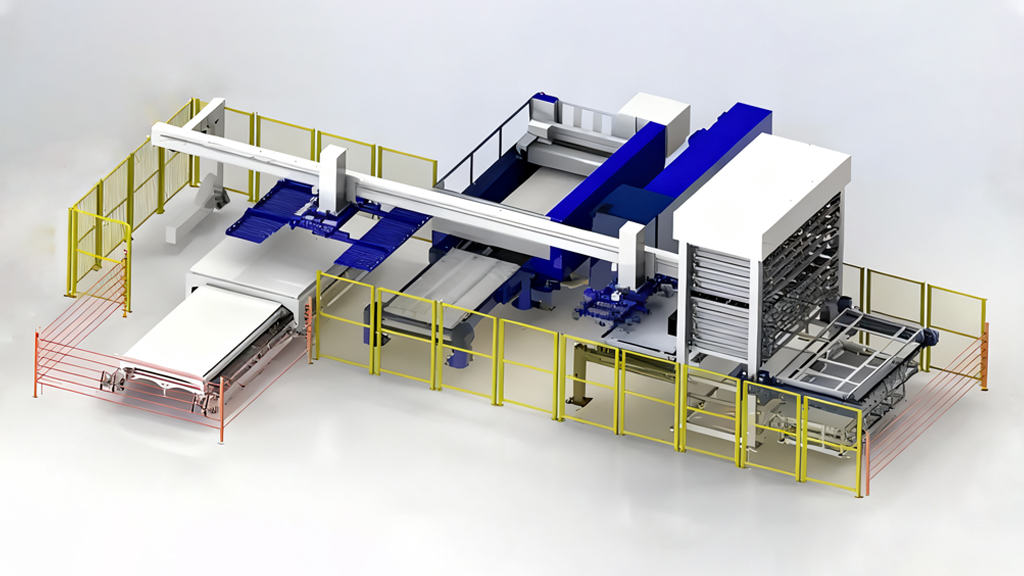

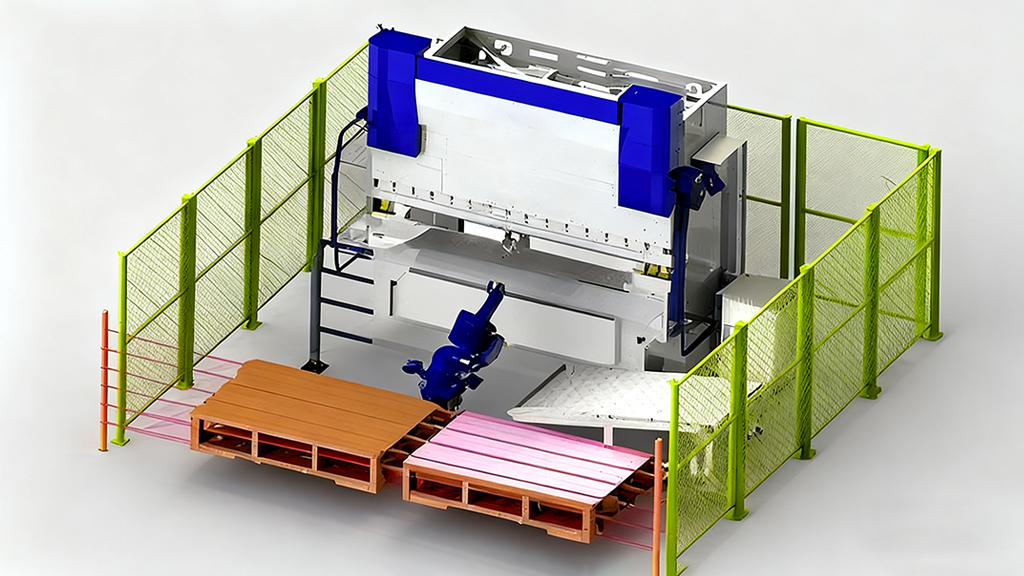

Automatic Sheet Metal Bending Robot Workstation

Integrating intelligent positioning, automatic clamping, precise bending and other functions to achieve semi-automatic/fully automated operations from sheet metal loading to finished product output, providing flexible, efficient and stable bending solutions for different production scenarios such as small and medium-sized batches of multiple varieties and large-scale standardization, becoming the core equipment for modern sheet metal enterprises to reduce costs and improve quality.

Multiple Sheet Metal Bending Flexible Production Line

With “flexibility, automation, and intelligence” as the core, breaking the limitations of traditional processing, providing full process solutions for multi variety, small batch, and high-precision sheet metal bending needs, it has become a key equipment for modern sheet metal enterprises to reduce costs, increase efficiency, and enhance core competitiveness.

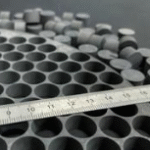

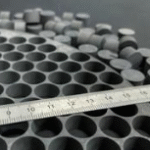

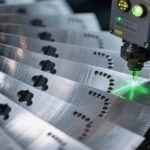

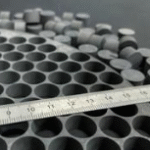

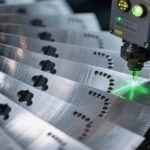

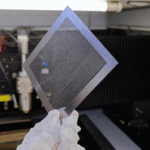

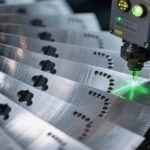

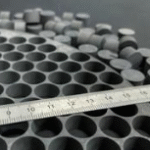

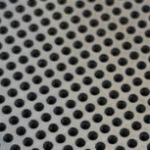

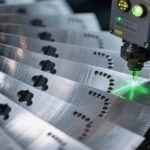

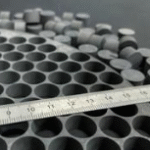

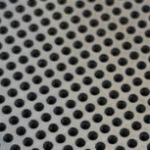

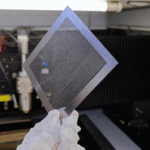

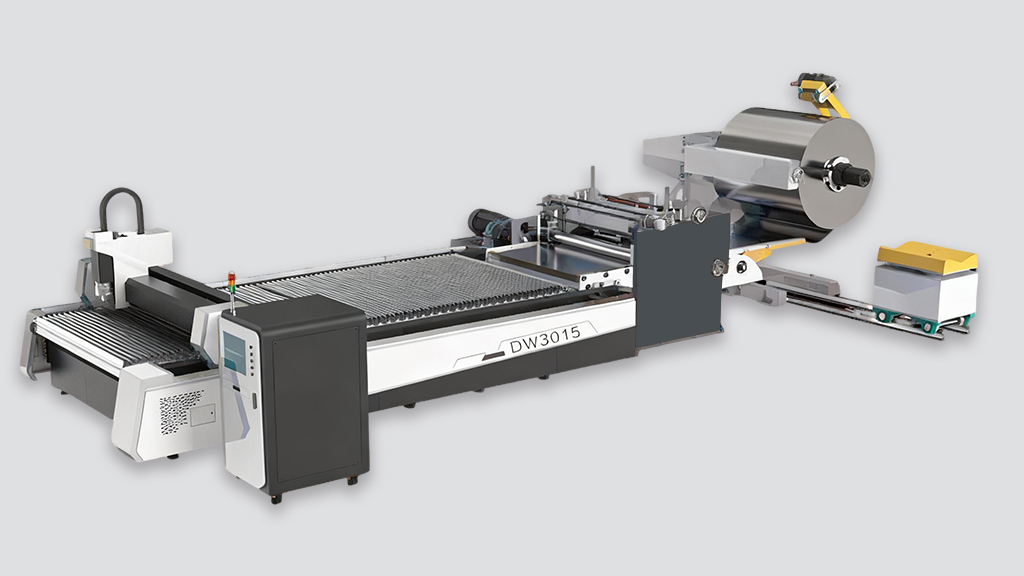

Metal Coiling Fed Fiber Laser Cutting Machine

Through the coordinated linkage of servo feeding system and laser cutting, seamless connection of “unwinding leveling cutting separation” is achieved, and the single shift production capacity is 3-5 times higher than traditional single cutting. Especially for batch gaskets, brackets, stamping replacement parts and other products, 24-hour uninterrupted production can be achieved, greatly shortening the order delivery cycle.

Steel Coiling Material Flexible Production Solution

Specially designed for continuous and batch cutting and cutting of steel coils (cold-rolled steel, hot-rolled steel, stainless steel, galvanized steel, etc.) (thickness 0.1-20mm, width 500-2000mm), realizing the full process automation operation from coil loading, laser cutting to finished product sorting, providing key support for enterprises to break through production bottlenecks and enhance product competitiveness.

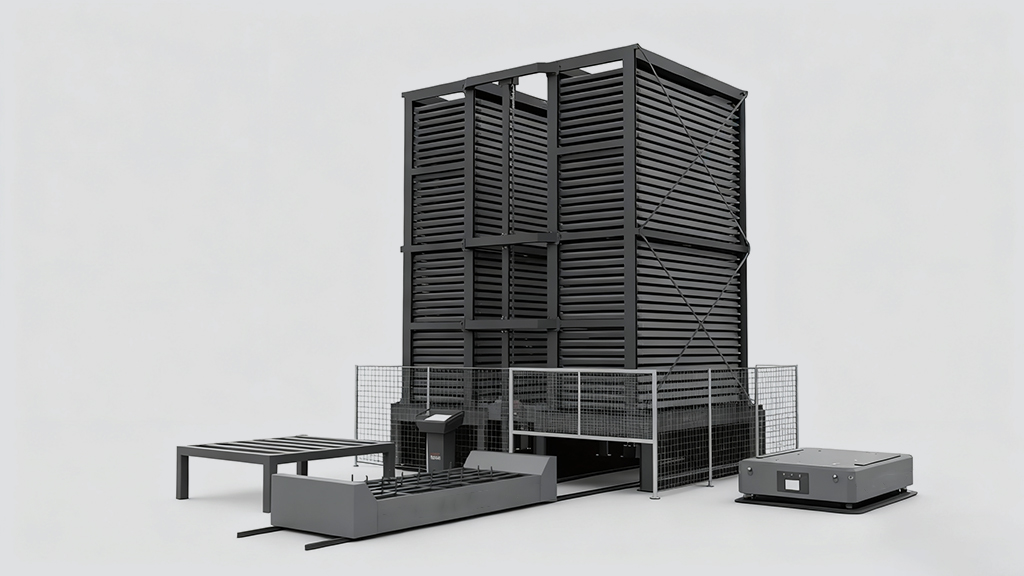

Intelligent Steel Plate Loading&Storage System

It is specifically designed for large-sized, heavy, and multi specification metal materials such as steel plates and sheet metal, achieving unmanned management of the entire process from raw material warehousing, storage, palletizing to outbound. It provides strong support for enterprises to reduce costs, increase efficiency, and enhance core competitiveness.

Are you searching for reliable and high-quality laser cutting/welding/cleaning/cladding machine suppliers with stable performance?

24/7 Professional Call Answering Service +86-18653133275.

About Dowell Laser

Jinan DOWELL Optoelectronic Equipment Co., LTD., after 15 years of professional commitment to optical fiber laser cutting machine, laser pipe cutting machine, laser welding machine and other laser cutting equipment production, research and development, sales work, to provide one-stop laser equipment solutions, is one of the domestic industry with few independent research and development capabilities. The company's whole series of products have passed CE, ISO9001 and other international certification.

Dowell Laser's existing technical employers more than 130+ research and development staff, and with 20, 5000 square meters of modern factory building, located in convenient transportation, Shandong Province, Jinan City, and has set up in Guangzhou, Shanghai, Beijing, Zhejiang, Fujian and other places with more than 20 distribution, in more than 30 countries and regions set up agents, products are exported to the United States, Russia, Germany, Turkey, southeast Asia, more than 60 countries and regions. The company fully absorbs the advanced ideas in the international laser field and independently develops a series of laser cutting products.

Cooperation Partner

Laser's growth is inseparable from the long-term support of our business partners. Dowell Laser's partner brands cover key areas such as core components, control systems, transmission and drives, ensuring stable equipment performance and quality.

Making the buying process easier and quicker.

How to get your own laser processing machine: step by step.

Similar machines can be found everywhere if you are looking for a new laser machine in today’s market. Choosing the right one for your company is challenging, regardless of your level of experience. You must shop around for the greatest deal, compare comparable features and prices, and be prepared for the transaction. When buying a new laser machine, a buyer should follow these four simple steps. You will learn how to find, evaluate, price, and bargain for your next machine.

01.

Research & Compare

Look into the most well-liked automatic laser processing machines available, read online reviews and ratings from professionals, select and list the machines that best fit your laser processing company from globally recognized brands like Dowell Laser, and compare features and prices.

02.

Locating & Testing

It is time to figure out how to find your options in action and find the ideal price for your budget after you have narrowed down your list. The next step is to request that the dealer test your design in a sample using the automatic laser processing equipment you wish to purchase.

03.

Get A Free Quote

You should ask for a free quote with laser processing machine configurations, warranty, cost breakdown, terms and conditions of payment, shipping and receiving, after-sales service, and support if the trial machining could satisfy your laser processing business needs.

04.

Transaction & Shipping

Now that everything is prepared, you must sign a purchase agreement with the dealer. After an agreement is reached, you can request that the laser cutting/welding/cleaning/cladding processing machines be manufactured and supplied to you promptly, as well as pay on the conditions that have been agreed upon.

05.

After-sales Service & Policies

Select a glass processing equipment manufacturer that can offer end users round-the-clock, professional, and attentive after-sales maintenance service assistance to ensure full life cycle maintenance for your glass equipment if the automatic equipment is meant to be used for an extended period of time.

Breaking through the limitations of traditional processing

One-stop Laser Processing Solution

Metal sheet and pipe cutting are an indispensable part of the industrial market. Metal laser processing machines can not only customize the appearance, but also develop professional cutting solutions. We provide you with the most affordable fiber optic metal cutting/welding/cleaning/cladding solutions.

15 years of production experience

15+ years of experience in laser equipment production and R&D, multiple invention patents;

OEM & ODM Avaliable

Support any form of OEM & ODM customization requirements, provide industry-integrated solutions; with all-free solution design, free sample supply, free installation guidance.

Weight:

The 25,000 square meter factory is large in scale, equipped with professional technicians, and provides one-stop laser equipment solutions.

Technical Certification

From "technical practitioner" to "certified expert", the difference is not only time, but also a dazzling "business card of strength".

Dowell Laser

Sourcing Laser Machine from Dowell Supplier

For Brand Owners

As an experienced laser processing machine manufacturer in China, we have worked with worldwide companies, taking their ideas from conception to fulfilling their desired CNC metal processing solutions. We walk the journey with you to ensure that we help you better define what you want and realize your brand’s perfect laser cutting/welding/cleaning/cladding solutions.

For Manufacturers & Suppliers

Our in-house modern production plant allows us to offer great quality options to appeal to your target customers. As a laser cutting/welding/cleaning/cladding machine manufacturer or supplier, you can trust that our streamlined manufacturing processes are here to provide you with the best outsourcing laser processing services and automatic production line in the market.

For Wholesalers

Customer’s Succeed Cases

Even in a fiercely competitive market environment, Dowell Laser never ask our clients to judge on those succeed cases, just ask our clients to judge us on those failure cases because we have so few…

Having specialized in precision sheet metal fabrication for many years, the inefficiency of small-batch orders was a persistent problem. Dowell laser machines, with their automatic parameter matching in the process library, allow even novice operators to get started quickly, reducing the rework rate to 0.5% and saving 300,000 RMB in material costs annually. Remote maintenance ensures uninterrupted production. We have already recommended it to our peers. Former Boss Laser Mexico regional distributor

Darrell Steward

CEO at Mitsubishi

I’ve been a Dowell distributor for 3 years. Their product range is comprehensive, and they hold their own patents, offering ample profit margins. Customer satisfaction is high, with a repurchase rate exceeding 40%. The after-sales team provides full support, eliminating the need to worry about customer complaints. Profits are stable, and it’s much easier than promoting competing products.

Renu

Purchasing Manager at Indian xxx Laser

We are a steel structure company, previously hampered by the inefficiency and high costs of flame cutting. After introducing the Dowell 20KW laser cutting machine, one person can now achieve the productivity of three, and material utilization has increased to 98%, saving us 100,00 Dollars in material costs annually. The equipment has a low failure rate, and after-sales service is prompt. We have already made a repeat purchase – a reliable choice.

Assam Ali

Owner at Yemen Exxx Co,.Ltd.

As a supplier to new energy vehicle manufacturers, we have high demands for precision and production speed. Dowell’s high-speed laser machine has enabled us to achieve a 99.8% pass rate for battery trays, increase production capacity by 67%, and facilitate quick line changes. The after-sales training is professional, ensuring stable operation and earning customer recognition.

32%

higher inbound conversions

5x

Theresa Webb

Senior Sales Manager atIBM

As an engineering machinery company, we faced challenges with inefficient and environmentally unfriendly thick plate processing. The Dowell 40kW laser cutting machine offers eight times the cutting efficiency of flame cutting, eliminates the need for post-cutting grinding, and meets environmental standards. With high utilization rates and a 45% reduction in costs, the return on investment is rapid, and we plan to purchase more units.

Tomáš Nádvorník

CEO at Czech XXX Machinery Co,.Ltd.

Recent Posts Laser Breaking News at Your Fingertips

Dowell Laser News&Blogger Ticker enables you to keep your visitors informed and engaged with up-to-date information. Display your website’s recent posts in a scrolling ticker format, ensuring that the latest content is highlighted and easily accessible.

Stay Informed with Real-Time Updates

How to choose the laser equipment for factory upgrade in 2025? Just read this article! Dowell Laser News Ticker allows your audience to stay connected and navigate through your most recent updates effortlessly.

-

Learn the latest laser cutting technology and practical knowledge

-

Read laser processing strategies for different materials

-

Unlock massive industry laser processing cases

Trending Now

Recent Blogs

Powerful and Advanced Customization Controls

Here is a popular selection of Laser basics, technologies, new machine tool launches, demonstrations, featured stories, latest news and events, headlines, applications, market reports, memorabilia, history and development prospects, safety protection guidelines, research explorations, as well as some how-to instructions.

-

Still troubled by the burrs and errors of traditional cutting?

-

Still compromising on design due to the difficulty of replicating complex patterns?

-

Accurate and efficient, laser processing is rewriting the definition of "cutting".

FAQ

Empower metals with 'laser cutting' as the blade

Eine Laserschneidmaschine für Rohre ist ein Spezialgerät, das mit einem fokussierten Laserstrahl Metall- und Nichtmetallrohre mit hoher Präzision schneidet, graviert oder markiert. Sie wird in verschiedenen Branchen wie der Automobilindustrie, der Luft- und Raumfahrt und der Fertigung häufig zum Erstellen komplexer Formen und Designs eingesetzt.

Yes, advanced laser cutting machines equipped with rotary attachments can cut 3D shapes and profiles on tubes, allowing for versatile design possibilities and applications.

- High precision and accuracy

- Saubere und glatte Kanten

- Minimaler Materialabfall

- Schnelle Schnittgeschwindigkeiten

- Fähigkeit, komplexe Formen und komplizierte Designs zu schneiden

- Edelstahl: Ideal für hochpräzise und saubere Schnitte.

- Kohlenstoffstahl: Weit verbreitet in industriellen Anwendungen.

- Aluminium: Leicht und einfach mit Lasertechnologie zu schneiden.

- Messing und Kupfer: Reflektierende Materialien, die unter besonderen Gesichtspunkten geschnitten werden können.

- Titan: Wird in der Luft- und Raumfahrt- und Medizinindustrie verwendet.

Zuverlässige Laserschneidmaschinen können bei spezialisierten Herstellern von Lasergeräten, Lieferanten von Industriemaschinen und seriösen Online-Marktplätzen erworben werden. Es ist wichtig, einen Lieferanten zu wählen, der hochwertige Maschinen, guten Kundensupport und zuverlässigen Kundendienst bietet.

Zuverlässige Laserschneidmaschinen können bei spezialisierten Herstellern von Lasergeräten, Lieferanten von Industriemaschinen und seriösen Online-Marktplätzen erworben werden. Es ist wichtig, einen Lieferanten zu wählen, der hochwertige Maschinen, guten Kundensupport und zuverlässigen Kundendienst bietet.

1. Die Kühlung verhindert das Aushärten des Materials, also die Wärmebehandlung.

2. Luftdruck bläst beim Schneiden die geschmolzene Metallschlacke weg.

3. Unterstützen Sie die Verbrennung.

Die Dicke, die ein Laserschneider schneiden kann, hängt von mehreren Faktoren ab, einschließlich der Art des Lasers, dem zu schneidenden Material und der spezifischen Konfiguration des Laserschneidsystems. Hier ein allgemeiner Überblick:

Art des Lasers: Es gibt verschiedene Arten von Laserschneidern, wie zum Beispiel CO2-Laser, Faserlaser und Nd:YAG-Laser. Jeder Typ verfügt über unterschiedliche Fähigkeiten und Leistungsstufen, die sich auf die maximale Schnittstärke auswirken.

Material: Die Art des zu schneidenden Materials hat großen Einfluss auf die maximale Dicke. Metalle wie Stahl können dicker geschnitten werden als Materialien wie Acryl oder Holz. Beispielsweise kann ein Hochleistungs-Laserschneider Stahl mit einer Dicke von bis zu 20–25 mm durchschneiden, die gleiche Maschine kann jedoch auch viel dickeres Acryl oder Holz durchschneiden.

Laserleistung: Die Leistung des Lasers ist ein entscheidender Faktor. Laser mit höherer Leistung (gemessen in Watt) können dickere Materialien durchschneiden. Beispielsweise könnte ein 1-kW-Laser Stahl mit einer Dicke von bis zu etwa 10 mm schneiden, während ein 4-kW-Laser bis zu etwa 20 mm oder mehr schneiden könnte.

Schnittgeschwindigkeit und Qualität: Es gibt oft einen Kompromiss zwischen der Dicke des Materials und der Qualität und Geschwindigkeit des Schnitts. Das Schneiden dickerer Materialien erfordert normalerweise eine langsamere Geschwindigkeit, um einen sauberen, präzisen Schnitt zu gewährleisten.

Laserkonfiguration und Fokus: Der Aufbau des Lasers, einschließlich der Brennweite der Linse und der Art der verwendeten Gasunterstützung (wie Sauerstoff oder Stickstoff), beeinflusst auch die maximale Schnittdicke.

Yes, safety precautions include:

- Tragen geeigneter Schutzausrüstung, wie z. B. Schutzbrille

- Sorgen Sie für ausreichende Belüftung, um die Belastung durch Dämpfe zu vermeiden

- Befolgen Sie die Richtlinien und Sicherheitshinweise des Herstellers

- Halten Sie den Arbeitsbereich sauber und frei von brennbaren Materialien

- Sachgemäße Schulung der Bediener im sicheren Umgang mit der Maschine

Ja, zu den Sicherheitsaspekten gehört das Tragen geeigneter Schutzausrüstung (z. B. eine Laserschutzbrille), die Gewährleistung einer ordnungsgemäßen Belüftung, um das Einatmen von Dämpfen und Partikeln zu vermeiden, die Einhaltung der Herstellerrichtlinien und das Freihalten des Arbeitsbereichs von brennbaren Materialien Außerdem ist es wichtig, dass Sicherheitsverriegelungen und Notabschaltfunktionen vorhanden sind.

Contact With Us

Dowell Laser can provide you with OEM ODM laser equipment manufacturing, customize different machine appearance, size, power, and provide you with the most affordable price on the market.