Choosing the right size for a laser cutting machine can be a daunting task, especially with the myriad of options available. But don’t worry, we’re here to Führung you through the process. Whether you’re a hobbyist working on small projects or a business owner looking for high-volume production capabilities, understanding the different sizes of laser cutting machines and their applications is crucial.

Laser cutting machines for metal come in a variety of sizes, each with its own advantages and disadvantages. The size of the machine will depend on the specific needs of the user, including the size of the metal sheets to be cut, the thickness of the metal, and the desired cutting speed.

What is Laser Cutting Machine Size for Metal

When selecting a laser cutting machine for metal fabrication, determining the appropriate size is crucial. The size of the machine directly impacts its capabilities, efficiency, and overall suitability for specific applications.

The laser cutting machine bed size is typically defined by the dimensions of its cutting bed. The cutting bed is the area where the metal sheet is placed for cutting. The size of the cutting bed determines the maximum size of the metal sheet that can be processed.

Factors to Consider When Choosing the Size

Material Size and Thickness

One of the first things to consider is the size and thickness of the material you’ll be working with. If you plan to cut large sheets of material, you’ll need a machine with a large working area. Conversely, for smaller projects, a compact machine may be sufficient.

Production Volume

If you’re running a business that requires high-volume production, you’ll need a machine that can handle larger workloads efficiently. This might mean opting for a larger machine that can process materials faster and in greater quantities.

Workspace and Space Availability

Consider the amount of space you have available in your workshop or facility. Larger machines require more space, not just for the machine itself but also for operation and maintenance.

Precision and Detail Requirements

The level of precision and detail you need in your cuts can also influence your choice. Smaller machines often provide higher precision for intricate designs, while larger machines are built for more substantial cuts and faster production.

Common Sizes of Laser Cutting Machines

For small-scale metal fabrication, a machine with a cutting bed size of around 300mm x 300mm may suffice. This size is suitable for cutting small parts, prototypes, and intricate designs. However, for larger-scale production, a machine with a cutting bed size of 1500mm x 3000mm or larger may be necessary.

Small Laser Cutting Machines

Small laser cutting machines typically have a working area of up to 130 x 130 mm 130*250mm 600*600mm. These machines are ideal for hobbyists, small businesses, and educational institutions. They are perfect for cutting small parts, intricate designs, and detailed engravings.

Medium Laser Cutting Machines

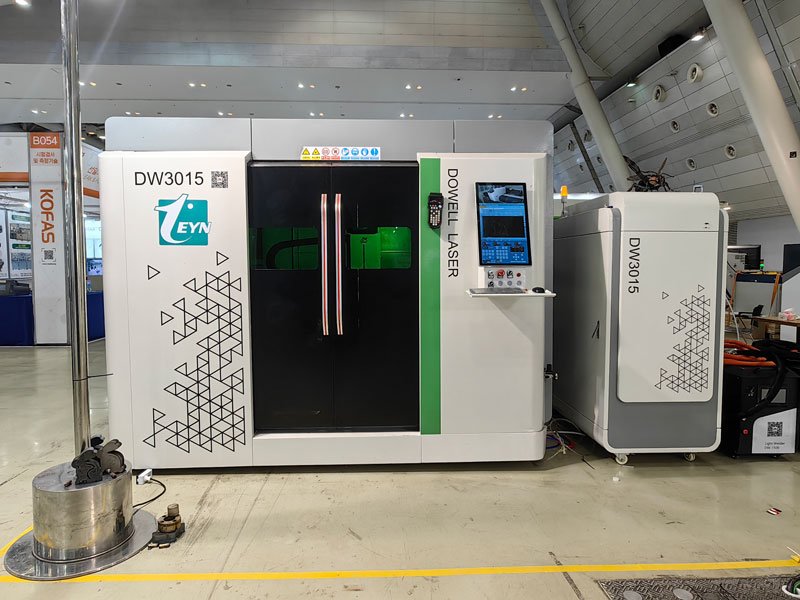

Laser cutting machine for medium-size have working areas ranging from 3000 x 1500 mm , 4000 x 2500 mm ,6000 x 1500 mm,6000 x 2500 mm,8000 x 2500 mm. They offer a balance between size and capability, making them suitable for medium sized businesses and workshops. They can handle a variety of materials and are versatile for different applications.

Large Laser Cutting Machines

Large size laser cutting machines come with working areas that exceed 12000 x 2500 mm,14000 x 2500 mm. These machines are designed for heavy-duty industrial applications, capable of cutting large sheets of material with high efficiency. They are perfect for manufacturing industries that require high-volume production.

Benefits of Different Sizes

Advantages of Small Laser Cutting Machines

- Portabilität: Small machines are easy to move and fit into compact spaces.

- Präzision: Ideal for intricate designs and detailed work.

- Cost-Effective: Generally more affordable, making them accessible for hobbyists and small businesses.

Advantages of Medium Laser Cutting Machines

- Vielseitigkeit: Suitable for a wide range of materials and applications.

- Balance: Offers a good balance between size and capability, making it a versatile choice for many users.

Advantages of Large Size Fiber Laser Cutting Machines

- Effizienz: Can handle large volumes of work quickly.

- Capability: Suitable for heavy-duty applications and large materials.

- Skalierbarkeit: Ideal for businesses looking to scale up production.

Applications Based on Machine Size

Small Machine Applications

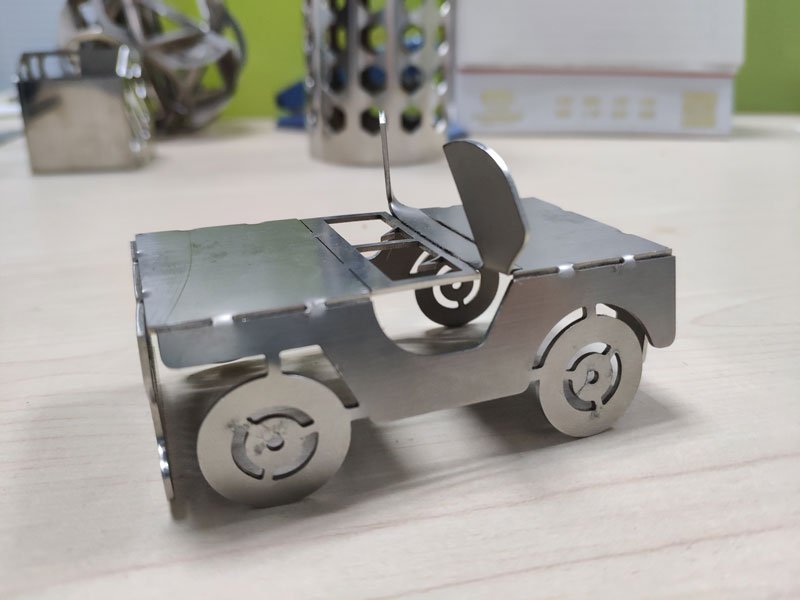

- Crafts and Hobbies: Perfect for creating small, detailed items such as jewelry, model parts, and Brauch engravings.

- Prototyping: Useful for producing prototypes and small batch production runs.

Medium Machine Applications

- Signage: Ideal for creating signs, plaques, and display items.

- Fabrication: Suitable for fabricating medium-sized parts and components.

Large Machine Applications

- Industrial Manufacturing: Essential for cutting large sheets of metal, plastic, and other materials in Herstellung.

- Automotive and Aerospace: Used for cutting parts and components in the automotive and aerospace industries.

Choosing the Right Laser Cutting Machine Size for Metal

Assessing Your Requirements

Start by evaluating the specific needs of your projects. Consider the types of materials you’ll be working with, the size of those materials, and the level of detail required.

Consulting with Experts

Don’t hesitate to consult with experts or Hersteller to get personalisiert advice. They can provide insights based on their experience and help you make an informed decision.

Considering Future Growth

Think about your future needs. If you anticipate growth in your production volume or the types of projects you’ll undertake, choose a machine that can accommodate that growth.

Abschluss

Choosing the right size laser cutting machine is essential for optimizing your workflow and achieving the best results. Whether you’re a hobbyist, a small business owner, or running an industrial operation, understanding the benefits and applications of different machine sizes will help you make the right choice.

FAQs

What is the ideal size for a hobbyist?

For hobbyists, a small laser cutting machine with a working area of up to 600 x 400 mm is typically ideal. It offers precision for detailed work and is cost-effective.

Can small laser cutting machines handle thick materials?

Small laser cutting machines can handle certain thick materials, but their capabilities are limited compared to larger machines. For thicker materials, medium or large machines are recommended.

How much space do I need for a large laser cutting machine?

A large laser cutting machine requires a significant amount of space, including room for operation and maintenance. Ensure you have ample space in your workshop or facility before purchasing.

What are the maintenance requirements for different sizes?

Maintenance requirements vary based on the size and type of machine. Generally, larger machines may require more frequent and detailed maintenance due to their complex components and higher usage rates.

How do I upgrade my laser cutting machine if my production needs change?

If your production needs change, you can upgrade by either purchasing a new machine that meets your new requirements or consulting with the Hersteller about possible upgrades or modifications to your existing machine.