As the industrial environment evolves, demand for cutting-edge technologies such as laser tube cutters continues to skyrocket. Tube laser cutters have revolutionized the way we shape and create with metal. This article delves into the world of Rohrlaserschneidmaschine prices, exploring the factors that affect cost, the different machine types, and where to find the best options.

What is Tube Laser Cutting Machines

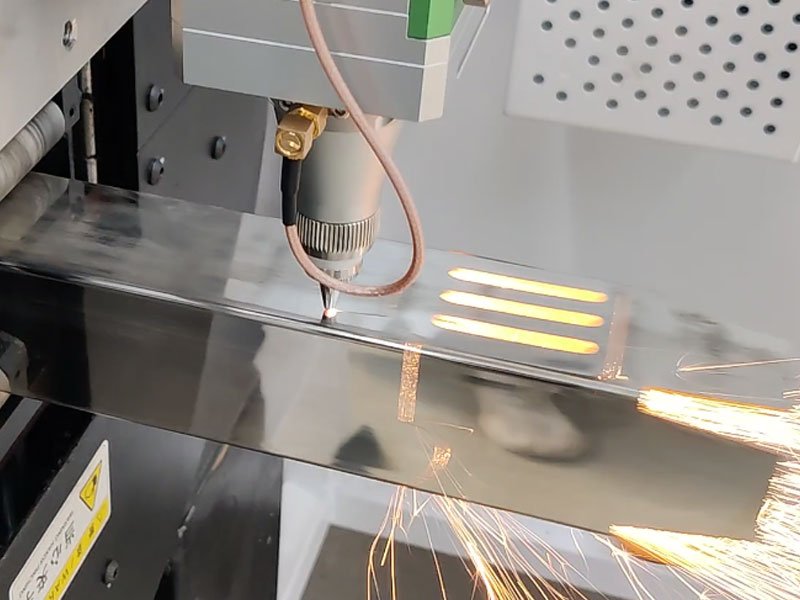

A tube laser cutting machine utilizes a focused laser beam to cut intricate shapes and profiles into hollow metal tubes. Unlike traditional cutting methods that generate heat and warping, laser cutting offers unmatched precision and clean cuts. This technology empowers Herstellung shops and Hersteller to create complex designs in various metal tubes, streamlining production and creating high-quality components.

Unlike traditional cutting methods that involve manual labor or mechanical cutting tools, tube laser cutting machines offer unparalleled precision. They can create intricate designs, complex shapes, and smooth edges on metal tubes with ease. This level of precision makes them ideal for industries that require high-quality cuts, such as automotive, aerospace, architecture, and more.

The operation of a tube laser cutting machine involves directing a focused laser beam onto the surface of the metal tube. The intense heat generated by the laser melts or vaporizes the material along the desired cutting path. The machine’s computer-controlled system ensures precise movements and accurate cuts based on pre-programmed designs or patterns.

Metal Laser Tube Cutting Machine Cost:

The cost of a metal pipe laser cutter typically ranges from $60,000 to $200,000 USD. Here’s a breakdown:

- Basic Models ($60,000 – $100,000): These entry level laser tube cutters handle moderate cutting capacities and offer basic features. They are suitable for small shops or those starting with laser cutting technology.

- Mid-Range Models ($100,000 – $150,000): These cnc laser tube cutters offer increased cutting power and capacity, along with some automation features, making them ideal for higher production volumes.

- High-End Models ($150,000 – $200,000+): These top-tier machines boast advanced features, high laser power, and the ability to handle large-diameter and thick-walled tubes. They cater to demanding applications in heavy industries.

Costs of Different Tube Laser Cutters

Beyond the basic metal tube laser cutting machine categories, there are additional factors influencing price based on specific needs:

- Fiber vs. CO2 Laser Cutting Machines: Fiber laser cutters are the dominant technology, offering efficiency, speed, and a wider material compatibility compared to CO2 lasers. While generally more expensive, fiber lasers provide a superior return on investment in the long run.

- 3-Axis vs. 5-Axis Laser Cutting Machines: 3-axis machines offer basic cutting capabilities on straight tubes. For intricate cuts on complex angles, 5-axis machines are necessary, but they come at a higher cost.

Factors Influencing Laser Tube Cutting Machine Price

The price of a tube laser cutting machine can vary significantly depending on several factors. Understanding these factors is crucial for businesses looking to invest in this technology:

Kraft und Leistung:

The power output of a tube laser cutting machine plays a significant role in determining its price. Higher-powered machines are capable of handling thicker and tougher materials but come at a higher cost.

Size and Capacity:

The size and capacity of the machine also impact its price. Machines with larger work areas or higher load capacities tend to be more expensive due to their ability to handle larger projects.

Markenreputation:

The reputation and brand value of the manufacturer can influence the price of a tube laser cutting machine. Well-established brands with a proven track record often command higher prices due to their reliability and quality.

Zusatzfunktionen:

Extra features such as automatic material feeding systems, advanced software, and integrated safety measures can increase the price of a tube laser cutting machine. These features enhance productivity and user experience, making them desirable for certain industries.

Types of Laser Tube Cutting Machines

Tube laser cutting machines come in different types, each designed for specific applications:

- Fiber Laser Tube Cutting Machines:

Fiber laser tube cutting machines utilize fiber lasers as their energy source. These machines are highly efficient, offering high-speed cutting with exceptional precision. They are suitable for various materials, including stainless steel, aluminum, brass, and more.

- CO2 Laser Tube Cutting Machines:

CO2 laser tube cutting machines use carbon dioxide lasers for cutting metal tubes. While they may not be as fast as fiber lasers, they are still capable of delivering precise cuts on a wide range of materials.

- Hybrid Laser Tube Cutting Machines:

Hybrid laser tube cutting machines combine the benefits of both fiber and CO2 lasers.

They offer versatility and flexibility, allowing users to switch between different laser sources depending on the specific requirements of their projects.

Where to Buy the Best Tube Laser Cutting Machine?

When it comes to purchasing a tube laser cutting machine, it is essential to choose a reputable supplier or manufacturer. The market offers a wide range of options, but not all machines are created equal.

- Manufacturer Reputation: Erforschen Sie die Hersteller‘s track record, customer reviews, and industry certifications.

- Machine Quality: Look for machines built with high-quality components and robust construction for longevity.

- Kundendienst: Reliable after-sales support, including spare parts availability and technical assistance, is essential for smooth operation.

Comparing Entry-Level vs. Industrial-Grade Tube Laser Cutters

When considering a tube laser cutting machine, it is essential to determine whether an entry-level or industrial-grade machine is more suitable for your needs:

Entry-Level Tube Laser Cutting Machines:

Entry level machines are typically smaller in size and have lower power outputs compared to industrial-grade machines. They are ideal for small businesses or those with limited budgets. While they may have certain limitations in terms of capacity and speed, they still offer excellent precision and can handle a wide range of applications.

Industrial-Grade Tube Laser Cutting Machines:

Industrial grade machines are larger, more powerful, and designed for heavy-duty use. They can handle larger workpieces, thicker materials, and operate at higher speeds. These machines are suitable for large-scale manufacturing facilities or businesses that require high-volume production with uncompromising precision.

How Different Industries Benefit from Fiber Tube Laser Cutting Machines

Automobilindustrie:

In the automotive industry, fiber tube laser cutting machines play a crucial role in manufacturing exhaust systems, chassis components, roll cages, and other intricate parts that require precise cuts.

Architecture and Construction:

Tubes cut by laser machines find their place in architectural marvels such as bridges, sculptures, staircases, and decorative elements. The ability to create complex shapes accurately allows architects to bring their designs to life.

Luft-und Raumfahrtindustrie:

Tube laser cutting machines are used in the aerospace industry to fabricate components for aircraft, rockets, and satellites. The precision and reliability of these machines ensure the highest standards of quality and safety.

Möbelherstellung :

In the furniture industry, laser cutting tube machines enable the creation of unique designs and intricate patterns on metal furniture pieces. This technology adds a touch of elegance and sophistication to modern furniture.

Abschluss

Laser tube cutting machines price have revolutionized metal Herstellung, offering unparalleled precision, efficiency, and versatility. The cost of these machines can vary depending on factors like cutting capacity, laser power, features, and brand. However, the investment in a high-quality tube laser cutting machine can bring significant benefits, including increased productivity, reduced waste, enhanced product quality, and expanded business opportunities.

Wann choosing a tube laser cutter, it’s essential to carefully consider your specific needs and budget.

FAQ

Is it Worth Buying a Tube Laser Cutting Machine?

Whether or not a tube laser cutting machine is worth the investment depends on your specific needs and business requirements. If you regularly work with metal tubes and require high-precision, efficient cutting, a tube laser cutting machine can be a valuable asset. These machines can significantly improve productivity, reduce waste, and enhance the quality of your products.

Price Difference Between New and Used Tube Laser Cutters

New tube laser cutting machines typically come with a higher price tag compared to used machines. This is due to the latest technology, reliable components, and Hersteller warranties that new machines offer. However, used machines can be a more budget-friendly option, especially for smaller businesses or those starting with laser cutting technology.

When considering a used tube laser cutting machine, it’s crucial to thoroughly inspect the machine’s condition, maintenance history, and remaining lifespan. It’s also advisable to factor in potential maintenance costs and ensure the availability of spare parts.