As the manufacturing industry continues to evolve, the demand for precision and efficiency in cutting processes has surged. CNC laser pipe cutting machines have emerged as a revolutionary solution, offering unparalleled accuracy and speed in cutting various types of pipes.

In this article, we will delve into the workings of CNC laser pipe cutting machines, exploring their principles, types, benefits, and how to choose the right one for your needs.

What is a CNC Laser Pipe Cutting Machine

A CNC (Computer Numerical Control) laser pipe cutter is an advanced cutting tool designed to cut and shape metal pipes with high precision. This machine utilizes a laser beam to perform the cutting process, which is controlled by a computer to ensure accuracy and consistency. CNC laser pipe cutters are used in various industries, including automotive, aerospace, construction, and Herstellung, due to their ability to produce intricate cuts with minimal waste.

Principle of Metal Pipe Laser Cutting Machine

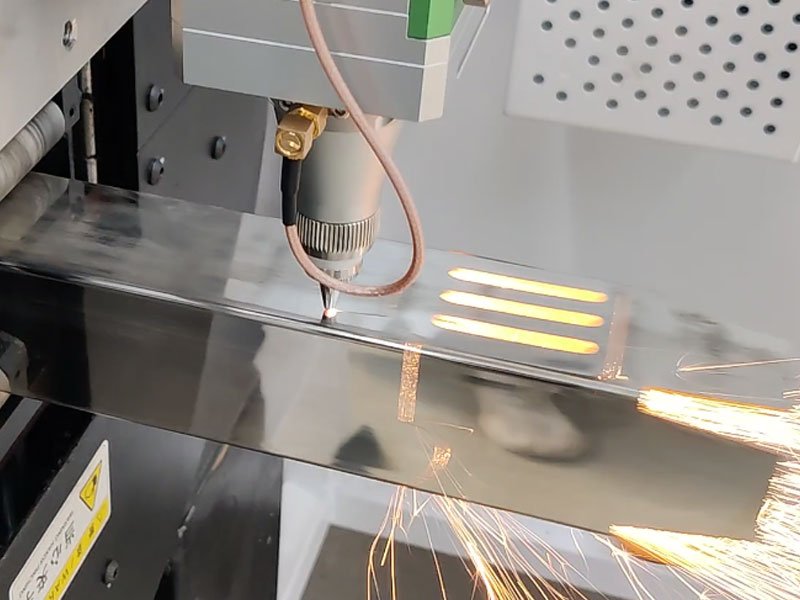

The core principle of a metal pipe laser cutting machine is the use of a high-powered laser beam to melt, burn, or vaporize the material being cut. The laser beam is generated by a laser source, typically a fiber laser, which is then directed through a series of mirrors or fiber optics to the cutting head.

The cutting head focuses the laser beam onto the surface of the pipe, heating it to a point Wo the material can be precisely removed. The movement of the pipe and the cutting head is controlled by a computer, allowing for complex shapes and patterns to be cut with extreme precision.

Types of Pipe Laser Cutter

- Faserlaserschneider: These use a solid-state laser to cut materials and are known for their efficiency and low maintenance costs. They are particularly effective for cutting thin to medium-thickness pipes.

- Hochleistungs-Rohrlaserschneider:This is a powerful laser cutter designed to handle thick-walled tubes and pipes made from various metals. It can withstand the extra weight and pressure required for cutting these sturdier materials.

- Seitlich montierter Laser-Rohrschneider:This type of laser cutter has the laser source mounted on the side of the machine, allowing for more flexibility in cutting longer pipes or accommodating larger workpieces.

- Automatic Tube Laser Cutter:This laser cutter features automation for loading, unloading, and cutting the tubes. This eliminates the need for manual intervention, improving efficiency and production speed.

- H-Strahl-Laserschneidemaschine: This machine is specifically designed to cut H-beam profiles, which are commonly used in structural steel applications. It can handle the complex geometry of these beams and ensure precise cuts.

Benefits of Laser Pipe Cutting Machine

- High Precision: CNC laser pipe cutters provide exceptional accuracy, enabling the production of complex geometries and intricate designs.

- Geschwindigkeit und Effizienz: These machines can cut materials at high speeds, significantly reducing production time and increasing throughput.

- Vielseitigkeit: Capable of cutting a wide range of materials and thicknesses, CNC laser pipe cutters are versatile tools suitable for various applications.

- Reduced Waste: The precision of laser cutting minimizes material waste, resulting in cost savings and more efficient use of resources.

- Clean Cuts: Laser cutting produces clean edges with minimal burring, reducing the need for secondary finishing processes.

Factors Should Be Considered When Maintaining a Cnc Laser Pipe Cutting Machine?

- Regular Cleaning: Ensure the machine’s lenses, mirrors, and cutting head are clean to maintain optimal laser performance.

- Scheduled Inspections: Conduct routine inspections to check for wear and tear on components such as the laser source, cooling system, and drive mechanisms.

- Software Updates: Keep the machine’s software updated to benefit from the latest features and improvements.

- Lubrication: Proper lubrication of moving parts is essential to reduce friction and prevent mechanical failures.

- Technical Support: Choose a machine with reliable technical support and readily available spare parts to minimize downtime in case of any issues.

How to Choose a Fiber Laser Pipe Cutting Machine

- Material and Thickness Compatibility: Ensure the machine is compatible with the types of materials and thicknesses you intend to cut.

- Leistung und Geschwindigkeit: Consider the laser power and cutting speed, as these factors will influence the machine’s performance and productivity.

- Software und Steuerungssysteme: Look for machines with user-friendly software and advanced control systems that offer flexibility and ease of use.

- Wartung und Support: Evaluate the maintenance requirements and the availability of technical support and spare parts.

- Cost and Return on Investment (ROI): Assess the initial cost of the machine against the potential benefits and savings it can provide in your specific application.

By understanding the intricacies of CNC laser pipe cutting machines, you can make informed decisions to enhance your Herstellung processes, ensuring precision, efficiency, and overall productivity.

FAQ

What Materials Can a Cnc Laser Pipe Cutting Machine Cut?

A CNC laser pipe cutting machine can cut a wide range of materials including stainless steel, carbon steel, aluminum, brass, copper, and other metal alloys. The versatility of these machines makes them suitable for various applications across different industries such as automotive, aerospace, and construction.

How Does a Cnc Laser Pipe Cutting Machine Improve Manufacturing Efficiency?

CNC laser pipe cutting machines significantly improve manufacturing efficiency by providing high cutting speeds, precision, and automation. The use of computer numerical control (CNC) ensures consistent and accurate cuts, reducing the need for manual intervention and minimizing errors. Additionally, the ability to cut complex shapes and patterns quickly allows for faster production cycles and increased throughput, leading to higher overall productivity.

Advantages of Using a Fiber Laser over a Co2 Laser for Pipe Cutting?

- EffizienzКитай Разработка Портативного Лазерного Сварочного аппарата

- Wartung: Fiber lasers have fewer moving parts and require less maintenance compared to CO2 lasers, resulting in lower maintenance costs and less downtime.

- Schneidgeschwindigkeit: Fiber lasers can cut thinner materials faster than CO2 lasers, increasing productivity for certain applications.

- Strahlqualität: The beam quality of fiber lasers is typically better, allowing for more precise and cleaner cuts, especially on thinner materials.