In the industrial market, co2 laser and fiber laser are the most commonly used fiber laser sources, but they are more commonly used in metal cutting, engraving and marking, and there are still many differences.

This article mainly focuses on laser welding brass vs co2. I hope it will help you choose the appropriate fiber laser.

Волоконно-лазерный станок для резки металла может быть более дорогостоящим в приобретении по сравнению с другими технологиями резки, что может удержать некоторые малые предприятия от инвестиций в них.

Fiber lasers are optical fibers whose active gain medium is doped with rare earth elements such as erbium, yttrium, neodymium, antimony, neodymium, thorium, and holmium. These elements provide the necessary light amplification without the need for external reflectors.

How fiber lasers work

The laser beam can be delivered to the target directly from the fiber or via a flexible cable, allowing high precision and flexibility in a variety of applications such as cutting, welding, and marking.

Fiber lasers are highly efficient, provide a large cooling surface area, and allow interaction between the pump light and the gain medium. The laser system is compact, energy-efficient, and capable of producing high-quality laser beams.

What is a CO2 laser

A gas-filled tube surrounding it serves as the laser medium. The gas mixture usually contains carbon dioxide (CO2) and other gases such as nitrogen (N2), helium (He), and sometimes hydrogen (H2) or xenon (Xe).

Fiber laser vs co2

| Factor | Faserlaser | CO2 Laser |

|---|---|---|

| Anwendungen | Metals, some non-metals, cutting, marking, welding | Non-metals, some metals, cutting, engraving, marking |

| Materialkompatibilität | Highly effective on metals, limited on non-metals | Highly effective on non-metals, less effective on metals |

| Cutting Speed and Precision | High speed and high precision | Moderate speed, high precision |

| Strahlqualität | High (very focused beam, minimal divergence) | Good (larger spot size than fiber lasers) |

| Power Consumption and Efficiency | Lower power consumption, higher efficiency | Higher power consumption, lower efficiency |

| Maintenance Requirements | Lower (solid-state, fewer moving parts) | Higher (gas refills, alignment checks) |

| Cost (Initial and Operational) | Higher initial cost, lower operational cost | Lower initial cost, higher operational cost |

Co2 vs fiber laser wave length

- CO2 Laser: Operates at a longer wavelength, typically around 10.6 micrometers (µm).

- Совместимость программного обеспечения: Operates at a much shorter wavelength, typically around 1.06 micrometers (µm).

This significant difference in wavelength directly impacts the types of materials each laser can effectively cut and process.

Fiber laser cut quality vs co2 laser

- Thinner materials: Fiber lasers excel at cutting thin materials with exceptional precision, producing clean edges with minimal dross and burrs.

- Thicker materials: While both can cut thicker materials, CO2 lasers often have a slight edge in terms of edge quality, providing smoother finishes.

- Materialtyp: The type of material also influences cut quality. Fiber lasers are particularly effective on reflective metals, while CO2 lasers tend to perform better on non-metals.

Factors Affecting Cut Quality:

- Laserleistung: Higher power typically leads to better cut quality.

- Nozzle type: The correct nozzle is crucial for optimal cut quality.

- Assist gas: The type and flow rate of assist gas can significantly impact results.

Fiber laser vs co2 laser speed

Thin materials: Fiber lasers cut thin materials much faster than CO2 lasers.

Thick materials: The difference in cutting speed between the two laser types becomes less pronounced for thicker materials, with CO2 lasers sometimes offering comparable speeds.

Factors Affecting Cutting Speed:

- Nozzle type and gas flow: The correct nozzle and gas settings optimize cutting speed.

- Material thickness: Thinner materials are cut faster with both types of lasers, but the advantage is more pronounced for fiber lasers.

- Materialtyp: The type of material being cut influences cutting speed. For instance, fiber lasers excel at cutting conductive materials like metals.

- Laserleistung: Higher laser power typically results in faster cutting speeds.

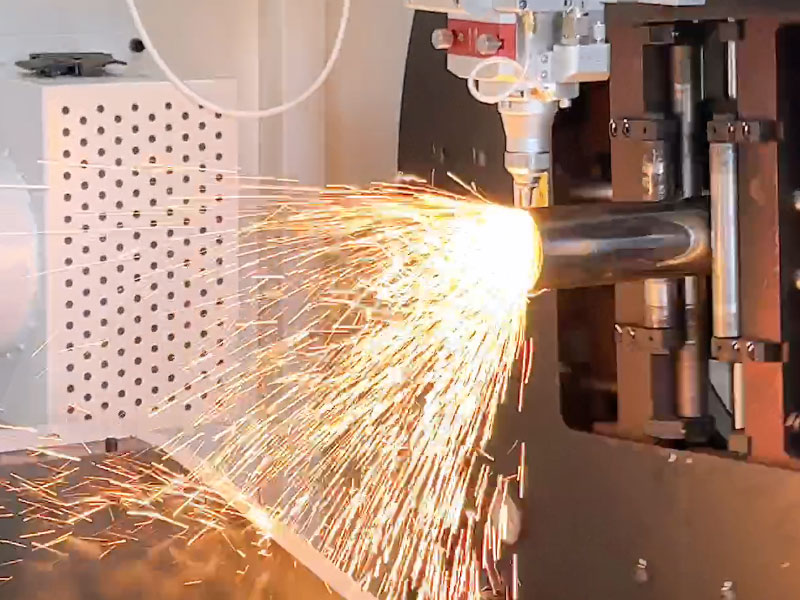

- Lasergeschnittenes Rohr

| Factor | Fiber Laser Cutting | CO2 Laser Cutting |

|---|---|---|

| Heat Affected Zone | Klein | Groß |

| Kerf Width | Klein | Groß |

| Schneidgeschwindigkeit | Fast | Slow |

| Strahlqualität | Good | Poor |

| Lebensdauer | Long | Short |

| Equipment Cost | Hoch | Niedrig |

| Cutting Edge Quality | Average | Good |

| Applicable Materials | Metalle | Non-metals |

| Applicable Thickness | Thin | Thick |

Co2 vs fiber laser wave length

CO2 Laser: Operates at a longer wavelength, typically around 10.6 micrometers (µm).

Совместимость программного обеспечения: Operates at a much shorter wavelength, typically around 1.06 micrometers (µm).

This significant difference in wavelength directly impacts how these lasers interact with materials and their suitability for different applications.

Advantage of fiber laser vs co2 laser

| Besonderheit | Beschreibung |

|---|---|

| Cutting Performance | |

| Higher Cutting Speed | Significantly faster cutting, especially for thin materials. |

| Superior Cut Quality | Produces cleaner cuts with minimal dross and burrs. |

| Vielseitigkeit | Effective on a wider range of materials, including metals. |

| Efficiency and Cost-Effectiveness | |

| Lower Energy Consumption | More energy-efficient, leading to lower operating costs. |

| Reduced Maintenance | Less frequent maintenance due to fewer components. |

| Longer Lifespan | Components generally have a longer lifespan. |

Disadvantages of co2 laser vs fiber optic laser

- Fiber laser cutting: Not suitable for cutting certain non-metallic materials, such as wood and plastic.

- CO2 laser cutting: The cutting speed is slow, the heat affected zone is large, and the cutting edge quality is poor.

Co2 vs fiber laser nitrogen consumption

| Besonderheit | CO2 Laser | Faserlaser |

|---|---|---|

| Nitrogen Consumption | Generally lower | Generally higher |

| Reasons | * Cutting process typically requires less nitrogen. * Material types often require less nitrogen. |

* Cutting process often requires a higher flow rate. * Material types like stainless steel demand more nitrogen. |

| Other Factors | * Laser power * Material thickness * Cutting speed * Nozzle type |

* Laser power * Material thickness * Cutting speed * Nozzle type |

Choose the right laser

Applying:

When selecting the right fiber laser, you need to determine whether you are performing laser cutting, laser engraving, or marking. The choice of material is crucial, as lasers have a significant impact on different materials.

Materialkompatibilität:

Some highly reflective materials require special processing options for lasers. Make sure the selected laser interacts effectively with the material you require.

Schnittgeschwindigkeit und Genauigkeit:

To determine the project, optical fiber, and carbon dioxide can meet the different needs of users in terms of cutting accuracy and speed.

Budget Fiber laser vs co2 laser cost:

When choosing the right fiber laser, it is necessary to have a certain budget, the cost of fiber laser vs CO2 is relatively higher, and it is more inclined to be used in the industrial market.

Fazit:

The main differences between fiber optic and CO2 lasers are materials, wavelengths, application fields, cutting quality and speed. If you want to choose the right laser, you need to choose the right laser according to your own needs and budget. If you want to know more about lasers, you can contact us or contact us Dowell laser.