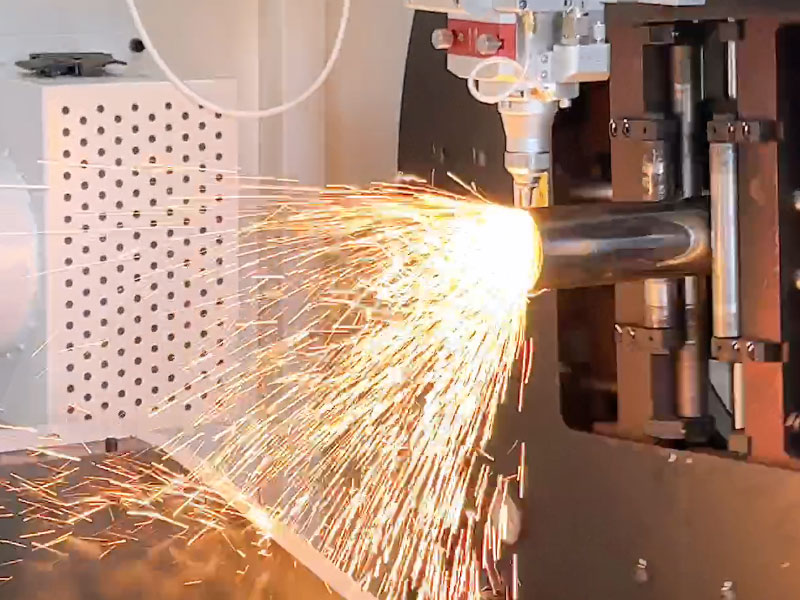

Laser technology is increasingly important in industrial manufacturing, especially in applications such as metal cutting, engraving, and marking. Common industrial lasers in the market include fiber optic and CO2 lasers.

This article mainly focuses on fiber laser vs co2. I hope it will help you choose the appropriate fiber laser.

What is a fiber laser?

How fiber lasers work

A fiber laser is a type of laser in which the active gain medium is an optical fiber doped with rare earth elements such as erbium, yttrium, neodymium, antimony, neodymium, thorium, and holmium. These elements provide the necessary light amplification without the need for external reflectors.

The laser beam can be delivered to the target directly from an optical fiber or via a flexible cable, allowing for high precision and flexibility in a variety of applications including cutting, welding and marking.

Fiber lasers are highly efficient due to the unique properties of fiber, which provide a large surface area for cooling and allow for long interaction lengths between the pump light and the gain medium. This results in a laser system that is compact, energy-efficient and capable of producing a high-quality laser beam.

Main features of fiber lasers :

- Wavelength: fiber laser vs co2 wavelength is shorter, resulting in better beam quality and cutting accuracy.

- Beam quality: Focused and narrow beam, suitable for complex designs and thin materials.

- Energy Efficiency: High efficiency, lower operating costs.

- Maintenance: fiber laser cutting vs co2 laser cutting, requires minimal maintenance.

What is a CO2 laser

How CO2 lasers work

A gas-filled tube surrounding it serves as the laser medium. The gas mixture usually contains carbon dioxide (CO2) and other gases such as nitrogen (N2), helium (He), and sometimes hydrogen (H2) or xenon (Xe).

Features of CO2 laser:

- Wavelength: co2 vs fiber laser wave length is longer, provides better material absorption, and is suitable for specific materials such as plastics and wood.

- Beam Quality: Wider and less focused beam, suitable for thicker materials and non-metal cutting/engraving.

- Cost: cost of fiber laser vs CO2, the overall upfront cost is lower.

Fiber laser vs co2

| Factor | Fiber Laser | CO2 Laser |

|---|---|---|

| Applications | Metals, some non-metals, cutting, marking, welding | Non-metals, some metals, cutting, engraving, marking |

| Material Compatibility | Highly effective on metals, limited on non-metals | Highly effective on non-metals, less effective on metals |

| Cutting Speed and Precision | High speed and high precision | Moderate speed, high precision |

| Beam Quality | High (very focused beam, minimal divergence) | Good (larger spot size than fiber lasers) |

| Power Consumption and Efficiency | Lower power consumption, higher efficiency | Higher power consumption, lower efficiency |

| Maintenance Requirements | Lower (solid-state, fewer moving parts) | Higher (gas refills, alignment checks) |

| Cost (Initial and Operational) | Higher initial cost, lower operational cost | Lower initial cost, higher operational cost |

Advantage of fiber laser vs co2 laser

Advantages of fiber laser cutting include:

- Smaller heat-affected zone: Fiber lasers have higher beam quality and stronger energy density, so the heat-affected zone during cutting is smaller. This reduces material deformation and thermal stress, improving cutting accuracy and surface finish.

- Smaller cutting slit: Fiber lasers have a narrower beam, so the cutting slit is smaller. This can reduce material waste and improve material utilization.

- Higher cutting speeds: Fiber lasers have higher power density, resulting in faster cutting speeds. This can improve production efficiency and reduce production costs.

Advantages of CO2 laser cutting include:

- Better cutting edge quality: The CO2 laser has a longer wavelength and can be better absorbed by non-metallic materials, so the cutting edge is smoother and more beautiful.

- Lower Equipment Cost: CO2 laser cutting machines generally cost less than fiber laser cutting machines.

Disadvantages of co2 laser vs fiber optic

- Fiber laser cutting: Not suitable for cutting certain non-metallic materials, such as wood and plastic.

- CO2 laser cutting: The cutting speed is slow, the heat affected zone is large, and the cutting edge quality is poor.

Co2 vs fiber laser nitrogen consumption

Although both carbon dioxide and fiber lasers can use nitrogen as an auxiliary gas during the cutting process, there are significant differences in their nitrogen consumption rates.

Carbon dioxide laser:

This is because CO2 lasers have weaker beams, resulting in more wasted energy, and require higher airflows to remove molten material and prevent oxidation.

It is estimated that CO2 lasers consume an average of 20% more oxygen and 40% more nitrogen than fiber lasers

Fiber optic laser:

Due to its highly focused and powerful beam, less nitrogen is used. This results in a cleaner cut, minimizes dross, and reduces reliance on assist gas to remove material.

While nitrogen consumption varies by material and thickness, overall nitrogen consumption is generally lower for fiber lasers compared to CO2 lasers.

Factors affecting nitrogen consumption:

Material being cut: Different materials require different gas flow rates. For example, cutting thicker metal may require a higher nitrogen flow rate compared to thin plate.

Cutting speed and thickness: Faster cutting speeds or thicker materials generally require more assist gas.

Machine settings: Gas flow rates and pressures are adjustable for both laser types, affecting nitrogen consumption.

Precautions:

Air can be used as an alternative assist gas for certain materials and CO2 laser applications, further reducing nitrogen consumption. However, air may affect cut quality and introduce oxidation and requires careful consideration.

Nitrogen cost can be an important factor Choosing the right laser type and optimizing cutting parameters can result in significant cost savings in the long run.

Fiber laser vs co2 laser speed quality

| Factor | Fiber Laser Cutting | CO2 Laser Cutting |

|---|---|---|

| Heat Affected Zone | Small | Large |

| Kerf Width | Small | Large |

| Cutting Speed | Fast | Slow |

| Beam Quality | Good | Poor |

| Lifespan | Long | Short |

| Equipment Cost | High | Low |

| Cutting Edge Quality | Average | Good |

| Applicable Materials | Metals | Non-metals |

| Applicable Thickness | Thin | Thick |

Choose the right laser

Applying:

When selecting the right fiber laser, you need to determine whether you are performing laser cutting, laser engraving, or marking. The choice of material is crucial, as lasers have a significant impact on different materials.

Material Compatibility:

Some highly reflective materials require special processing options for lasers. Make sure the selected laser interacts effectively with the material you require.

Cutting speed and accuracy:

To determine the project, optical fiber, and carbon dioxide can meet the different needs of users in terms of cutting accuracy and speed.

Budget Fiber laser vs co2 laser cost:

When choosing the right fiber laser, it is necessary to have a certain budget, the cost of fiber laser vs CO2 is relatively higher, and it is more inclined to be used in the industrial market.

Conclusion:

The main differences between fiber optic and CO2 lasers are materials, wavelengths, application fields, cutting quality and speed. If you want to choose the right laser, you need to choose the right laser according to your own needs and budget. If you want to know more about lasers, you can contact us or contact us Dowell laser.