Metal square tubes are relatively expensive in the industrial market. “How to cut steel square tubes” is a topic that everyone is more concerned about. Finding a reasonable, effective, economical and affordable CNC automation equipment is the best way.

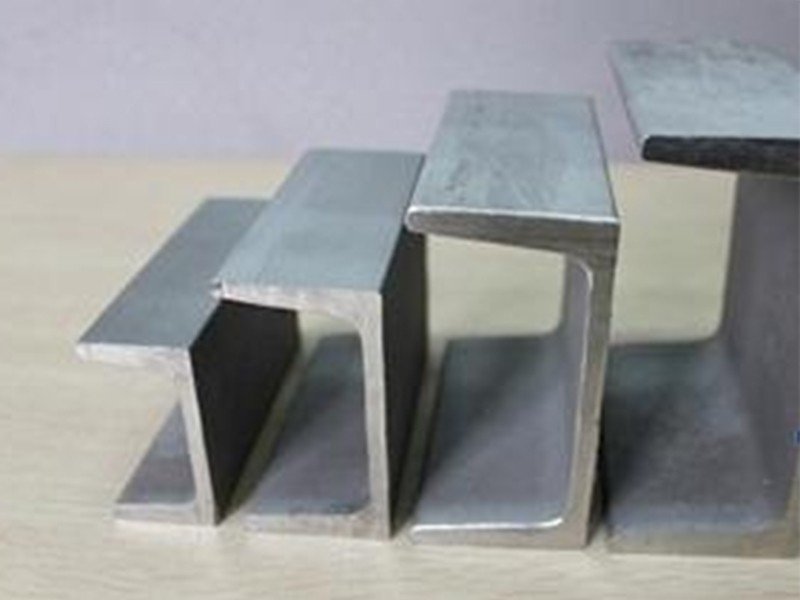

What is Steel Square Tubes

Square steel pipe, also known as a square steel pipe, is a steel pipe with a hollow middle and square crosssection around it. The sides are equal in length and are rolled just after processing. It has the characteristics of light weight, high strength, corrosion resistance and easy processing and molding.

Metal Laser Cutting Technology

Laser cutting technology is the most efficient and precise metal cutting solution currently used in the industrial field. A high-power laser beam is used to melt or vaporize material, allowing for precise and efficient cutting. Laser square tube cutting offers many advantages over traditional cutting methods, such as increased speed, reduced waste, and improved accuracy.

Factors to Consider Before Laser Cutting

Several factors should be considered before laser cutting steel square tubes. First and foremost is the thickness of the material. Laser cutting machines have limitations regarding the maximum thickness they can cut effectively. Additionally, the type of steel being used should be taken into account as different alloys may require specific laser settings.

Types of Laser Cutting Steel Tubes

Several laser cutting techniques can be employed for steel square tube cutting:

| Type of Laser Cutting | Description | Advantages | Common Applications |

|---|---|---|---|

| CO2 Laser Cutting | Uses CO2 gas to generate the laser beam; known for its versatility and ability to cut non-metallic materials, metals, and steel tubes. | High precision, good for thick materials, versatile. | Cutting, boring, engraving |

| Fiber Laser Cutting | Utilizes a solid-state laser source that creates a beam through fiber optic cables; highly efficient with metals, including steel tubes. | High efficiency, excellent precision, energy-saving. | Cutting thin to medium-thick steel tubes |

| Nd:YAG/Nd:YVO4 Lasers | Solid-state lasers using neodymium-doped crystals; Capable of producing high energy for precise cutting. | High energy, focused cutting, good for detailed work. | High-precision cutting, welding, engraving |

| Disk Lasers | Features a disk shaped laser medium, combining the benefits of fiber and CO2 lasers, suited for high-quality cuts on thick steel tubes. | High power efficiency, excellent beam quality. | Cutting thick steel tubes, high-quality cuts |

Advantages of Laser Cutting Steel Square Tubes

Laser cutting steel square tubes offers several advantages over traditional cutting methods:

- Precision: Allows for precise cuts with minimal deformation, ensuring precise dimensions and tight tolerances.

- Speed: Much faster than manual or mechanical cut square tubing methods, saving labor and improving productivity. We can add auxiliary equipment to achieve batch square tube cutting,quickly cut square.

- Versatility: Can handle a variety of materials and thicknesses, making it suitable for a variety of applications.

- Minimal Waste: Minimize material waste, thereby saving costs and reducing environmental impact.

Selecting the Right Laser Cutting Machine for Steel Square Tubes

CNC square tube cutting machine power output, bed size, maximum thickness capacity and compatibility with different types of steel square tubes. Laser cut square tube budget, it is recommended to consult an expert or square tube laser cutting machine manufacturer to determine the best machine for your specific project requirements.

How to use Laser Cutting Steel Square Tubes

The following are the cutting steps using square tube laser cutting:

Prepare the Material:

Ensure that the steel square tube is clean and free from any contaminants that may affect the laser cutting process.

Set Up the Machine:

Adjust the laser settings according to the material type and thickness. This includes selecting appropriate power levels, focal lengths, and feed rates.

Positioning:

Securely position the steel square tube on the machine’s bed or fixture to prevent movement during cutting.

Test Cut:

Perform a test cut on a scrap piece of material to verify that all settings are correct before proceeding with the actual cut.

Start Cutting:

Initiate the laser cutting process by activating the machine’s controls or software program. Monitor the cut progress closely to ensure accuracy and quality.

Cutting square tube Process

The process of using a laser pipe cutting machine to cut pipes requires multiple tests to ensure the accuracy of the cutting.

Test Cuts

- Perform test cuts on scrap material to fine-tune the machine settings.

- Adjust laser power, cutting speed, and focus if necessary to achieve the desired cut quality.

Material Alignment

- Securely position the steel square tube on the laser cutter’s bed.

- Ensure the material is flat and stable to prevent any movement during cutting.

Cutting Execution

- Initiate the cutting process by starting the laser cutter, following the prepared design path.

- Monitor the cutting to ensure it follows the desired pattern and to quickly respond to any potential issues.

Quality Checks

- Regularly inspect the first few pieces for accuracy, edge quality, and overall finish.

- Adjust machine settings if the initial pieces do not meet the required specifications.

Traditional cutting metal square tube method

Cutting steel pipes can be accomplished using various methods, including:

Hacksaw:

A hacksaw is a manual cutting tool that can be used to cut through steel pipes. It requires physical effort and may not be suitable for large-scale projects.

Angle Grinder:

An angle grinder equipped with a metal cutting disc can quickly and efficiently cut through steel pipes. However, caution must be exercised to ensure safety during the process.

Pipe Cutter:

A pipe cutter is a specialized tool designed specifically for cutting pipes. It utilizes a sharp wheel that gradually cuts through the pipe as it is rotated around it.

How to cut aluminium square tube

Cutting thin metal pipes made of copper or aluminum can be achieved using similar methods as cutting steel pipes:

- 1. Hacksaw: A hacksaw with a fine-toothed blade can effectively cut through thin metal pipes without causing excessive damage or deformation.

- 2. Tubing Cutter: A tubing cutter is an ideal tool for cutting thin metal pipes as it provides clean and precise cuts without distorting the material.

What are some alternatives to using a hacksaw for cutting metal tubing?

While hacksaws are commonly used for cutting metal tubing, there are alternative methods available:

- Reciprocating Saw: A reciprocating saw, also known as a “Sawzall,” equipped with a metal-cutting blade can quickly and efficiently cut through metal tubing.

- Band Saw: A band saw with a suitable blade designed for cutting metal can provide accurate and clean cuts on various sizes of metal tubing.

How to cut steel square tube 22.5 degrees

| Method | Advantages | Disadvantages | Tools Needed |

|---|---|---|---|

| Using a Miter Saw | Most accurate and efficient method | Requires a miter saw | Miter saw, safety glasses, clamps, marker |

| Manually Marking and Cutting | Does not require a miter saw | Less precise | Safety glasses, gloves, marking tools (marker, square, protractor), cutting tool (hacksaw, reciprocating saw, or angle grinder) |

Using a Miter Saw

- Set the miter saw angle to 22.5 degrees.

- Clamp the square tube to the miter saw bed.

- Mark the cutting line on the square tube with a marker.

- Turn on the miter saw and slowly lower the blade into the square tube along the marked line.

Manually Marking and Cutting

- Clamp the square tube to a secure work surface.

- Use a square to draw a straight line along the length of the tube where you want to make the cut.

- Using the protractor or angle finder, measure and mark a 22.5-degree angle from the reference line on either side of the square tube.

- Use a straight edge to connect the two angle markings across the width of the square tube. This line represents your cutting line.

- Following the marked line, carefully cut through the square tube using your chosen cutting tool.

How to cut square tube 45 degrees

| Method | Advantages | Disadvantages | Tools Needed |

|---|---|---|---|

| Using a Miter Saw | * Preferred method for clean and precise cuts. * Quick and easy to use. * Can make multiple cuts with ease. | * Requires a miter saw, which can be expensive. * Not as portable as manual methods. * Can be dangerous if not used properly. | * Miter saw * Safety glasses * Clamps * Marker |

| Manually Marking and Cutting | * Does not require a miter saw. * More portable than using a miter saw. * Can be used in tight spaces. | * Requires more time and effort. * May not be as precise as using a miter saw. * Can be dangerous if not used properly. | * Safety glasses * Gloves * Marking tools (marker, square, protractor) * Cutting tool (hacksaw, reciprocating saw, or angle grinder) |