Traditional industrial cleaning has many disadvantages. It not only damages the surface of metal materials but also has some risk problems that are difficult to solve. The advent of laser cleaning machine has entered a revolutionary era, providing accurate, efficient and safe cleaning solutions. But many customers have a lot of questions about Clean Laser Machine Price. This article delves into everything you need to know about handheld laser cleaning machines, their features and the factors that affect their price tags.

What is a Handheld Laser Cleaning Machine?

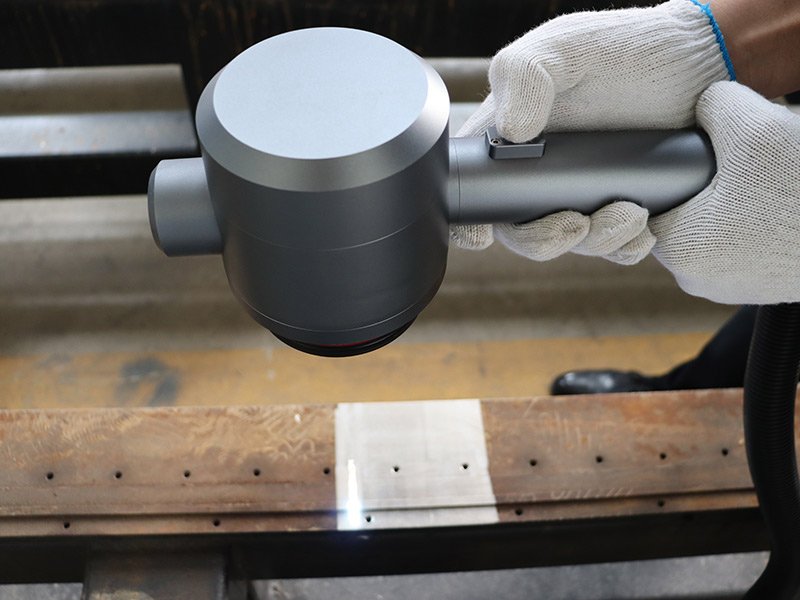

A handheld laser cleaner is a portable device that uses a concentrated laser beam to remove surface contaminants. Unlike traditional cleaning methods that rely on chemicals or abrasives, laser cleaning uses a highly focused laser beam to precisely vaporize and remove dirt, rust, paint, oil and other unwanted materials without damaging the underlying substrate.

Fiber Laser Cleaning Machine Industries:

- Fabrication: Removes weld scale, spatter and rust from metal.

- Automotive: Clean engine parts, remove paint and primer, and restore vehicle exteriors.

- Mold Remediation: Removing mold and mildew from surfaces.

- Shipbuilding and Marine: Cleaning welds, hulls and decks.

- Electronics: Repair precision electronic components and circuit boards.

- With their versatility and precision, handheld laser cleaners are quickly becoming the cleaning method of choice across many industries.

How Does a Handheld Laser Cleaning Machine Work?

The core functionality of a handheld laser cleaning machine revolves around the principle of photoablation. Here’s a breakdown of the working process:

- Laser Beam Generation: The machine’s internal laser source generates a high-powered laser beam.

- Beam Delivery: The laser beam is channeled through a fiber optic cable towards the handheld cleaning gun.

- Scanning System: The cleaning gun houses a scanning system that directs the laser beam onto the target surface.

- Photoablation: Upon contact with the surface, the laser beam’s energy is absorbed by the contaminant material. This concentrated energy rapidly heats and vaporizes the targeted material, effectively removing it from the underlying surface.

The precise nature of the laser beam allows for controlled cleaning, minimizing the risk of damage to the substrate. Additionally, the adjustable parameters like pulse duration and power density enable operators to tailor the cleaning process to specific materials and contaminants.

Laser Cleaning Machine for Sale

With the growing demand for clean laser machines, numerous manufacturers and distributors offer various models. Here are some key aspects to consider when searching for laser cleaning machines for sale:

- Power Source: Laser cleaning machines come in two primary types – continuous wave (CW) and pulsed. Choose based on your specific cleaning needs (discussed in a later section).

- Power Output: The power output of the laser directly impacts its cleaning efficiency. Higher power machines remove tougher materials faster.

- Portability: Consider the size and weight of the machine for optimal maneuverability in your workspace.

- Safety Features: Ensure the machine incorporates essential safety features like protective eyewear and emergency shut-off switches.

- Warranty and Support: Reliable after-sales support and warranty coverage are crucial for long-term investment protection.

By researching reputable vendors and comparing these factors, you can find the ideal laser cleaning machine for your specific application and budget.

How Much Is a Handheld Laser Cleaning Machine Price?

- Low power pulse handheld laser cleaning machine: $5,000 – $10,000

- High power continuous wave (CW) laser cleaner: $7,000 – $15,000

Factors Affecting Laser Cleaning Machine Price

The price of a handheld laser cleaning machine can vary significantly depending on several factors, including:

- Power Output: Machines with higher power outputs naturally come with a higher price tag.

- Pulse vs. Continuous Wave (CW): Pulsed laser machines are generally more expensive than CW machines of similar power.

- Brand and Manufacturer: Reputable brands with advanced technology might command a premium price.

- Additional Features: Machines with advanced features like automatic cleaning head adjustments or integrated fume extraction systems will cost more.

- Customization: Custom-built machines tailored to specific applications may have a higher price tag.

Features of Laser Rust Removal Machine

Industrial laser cleaning machine excel at rust removal due to several unique features that make them a superior choice over traditional methods. Here’s a breakdown of some key features that contribute to their effectiveness:

- Precise Cleaning: Unlike abrasive methods like sandblasting or wire brushing, laser cleaning utilizes a highly focused laser beam. This allows for pinpoint removal of rust without affecting the surrounding material. This precision is crucial for cleaning delicate components, intricate geometries, and areas with tight tolerances.

- Minimal Substrate Damage: The laser beam interacts with the rust through a process called photoablation. During photoablation, the laser light is absorbed by the rust, causing it to rapidly heat and vaporize. Since the laser beam is precisely targeted, the minimal heat transfer to the underlying metal minimizes the risk of warping or damaging the substrate. This is a significant advantage compared to traditional methods that can gouge or scratch the surface.

- Controlled Ablation Depth: The power density and pulse duration of the laser beam can be precisely controlled. This allows operators to tailor the cleaning process to remove only the desired depth of rust without affecting the underlying healthy metal. This control is particularly beneficial for applications where preserving the original surface profile is critical.

- Reaches Inaccessible Areas: The focused nature of the laser beam allows for cleaning in hard-to-reach areas and complex geometries. Traditional methods like grinding or sandblasting often struggle to reach these areas effectively. This makes laser cleaning ideal for cleaning internal components, weld zones, and intricate parts with tight spaces.

- Fast and Efficient Cleaning: Laser cleaning machines offer rapid cleaning speeds, significantly reducing cleaning times compared to manual methods. This translates to increased productivity and cost savings.

- Environmentally Friendly: Laser cleaning eliminates the need for harsh chemicals or abrasive media. This reduces the risk of hazardous waste disposal and creates a safer work environment for operators. Additionally, the minimal energy consumption of laser cleaning makes it an environmentally friendly solution.

- Versatility: Laser cleaning machines are not limited to just rust removal. They can effectively remove various contaminants like paint, oil, grease, and weld spatter from a wide range of metals, including ferrous and non-ferrous alloys. This versatility makes them a valuable tool for various industrial applications.

- Automated Cleaning: Many laser cleaning machines offer automated cleaning functionalities. These include features like automatic cleaning head adjustments, scanning patterns, and integration with robotic arms. Automation allows for consistent cleaning results, reduces operator fatigue, and improves overall cleaning efficiency.

Advantages of Laser Rust Cleaning

Laser rust cleaning offers several compelling advantages over traditional rust removal methods:

- Effective on Various Surfaces: Laser cleaning can effectively remove rust from a wide range of metals, including ferrous and non-ferrous alloys.

- Reaches Inaccessible Areas: The precise laser beam can reach hard-to-reach areas and intricate geometries, unlike traditional methods.

- No Secondary Abrasives or Chemicals: Laser cleaning eliminates the need for hazardous chemicals or abrasive media, reducing environmental impact and safety concerns.

- Minimal Surface Preparation: Laser cleaning often requires minimal or no surface preparation, saving time and effort.

- Cost-Effective in the Long Run: While the initial investment in a laser cleaning machine may be higher, the long-term cost savings due to reduced labor, material usage, and environmental compliance can be significant.

How to Choose Between Continuous and Pulse Laser Cleaning Machine?

The choice between a continuous wave (CW) and pulsed laser cleaning machine depends on the specific application and the type of contaminant to be removed:

Continuous Wave (CW) Laser Cleaning Machines:

Suitable for: Removing soft contaminants like paint, organic matter, and polymer coatings.

Advantages: Efficient for removing large areas of contaminants, typically offer lower cost per watt.

Pulsed Laser Cleaning Machines:

Suitable for: Removing hard contaminants like rust, weld spatter, and scales.

Advantages: Effective in breaking down and removing tightly bonded contaminants, minimize thermal damage to the substrate.

In general, pulsed laser machines are better suited for rust removal due to their ability to shatter and vaporize hard materials. However, CW machines can be a cost-effective option for removing softer contaminants over large surface areas.

How Finding Reliable Suppliers for Clean Laser Machines

Finding a reliable supplier of cleaning laser machines is critical to ensuring the quality, performance, and long-term support of your investment.

Industry Reputation: Research the supplier’s reputation in the laser cleaning industry. Check out online reviews, industry forums, and testimonials from existing customers.

Experience and expertise: Make sure the supplier has experience providing laser cleaning solutions for applications similar to yours.

Product Quality: Ask about the quality of laser components, safety features and overall machine construction.

Technical Support: Evaluate the vendor’s ability to provide responsive and knowledgeable technical support before, during, and after the sale.

Warranty and Service: Confirm the warranty coverage and service options offered by the supplier.

By carefully considering these factors, you can find a reliable supplier who can provide a high-quality laser cleaning machine and the necessary support to ensure its effective operation for years to come.

FAQ

1.How to Clean Laser Machine Lens?

Laser rust removal machines offer a precise, efficient, and safe solution for rust removal in various industrial applications. They are becoming increasingly popular due to their ability to protect delicate components, reduce cleaning times, and minimize environmental impact.

2.Are there any discounts or promotions available for purchasing clean laser machines?

Certainly!

When looking to purchase a cleaning laser machine, it’s always a good idea to keep an eye out for discounts and promotions offered by manufacturers or suppliers. These discounts can help you save on the overall cost of your machine, making it more affordable for your business. It is recommended to contact different vendors and inquire about any ongoing promotions or upcoming sales.

3.Which Platforms to Buy Cheapest Laser Cleaning Machine

When looking to buy the cheapest laser cleaning machine, consider popular online platforms like Alibaba, eBay, and Amazon to get competitive prices. These platforms offer a wide selection from different sellers, allowing you to compare prices and features to find the best deal.