With the rapid development of technology, handheld laser engraving machines are very popular in our lives. For many DIY users, laser engraving of acrylic is very popular among users. However, many users are not very clear about the use of settings and other parameters after buying it.

This article will explain the parameters of laser engraving transparent acrylic, I hope it will be helpful to you.

Types of acrylic materials

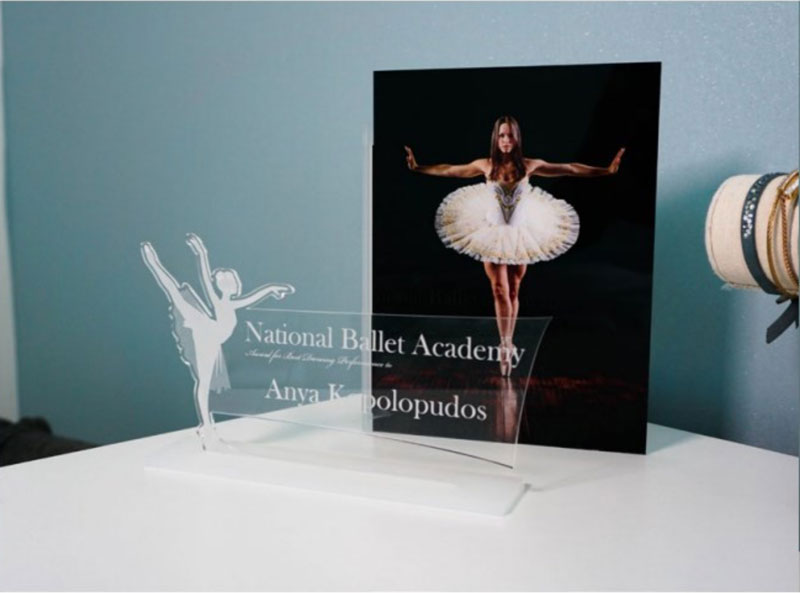

- Cast acrylic: Suitable for engraving, can produce a clear frosted effect. Suitable for awards and decorations.

- Extruded acrylic: More suitable for cutting, the edge is smooth after cutting, but the engraving effect is not as obvious as cast acrylic.

It is easier to manufacture extruded acrylic than cast acrylic, which makes it cheaper. In addition, extruded acrylic laser engraves clean and smooth, and the edges are flame-polished. Laser engraved products look sharp, rather than the frosted appearance of cast acrylic. It is also softer and tends to stick during rotary engraving.

Clear Acrylic for Laser Engraver Setting Parameters

Power:

For clear acrylic, a lower power setting is usually required. This is because clear acrylic has a relatively low density and too high a power setting may cause the material to deform or burn.

A laser power of 20% – 50% is generally recommended, depending on the thickness and type of acrylic.

Speed:

Higher speeds are generally used for engraving to achieve better results. A setting of 300 – 600 mm/s is recommended to ensure that too much heat is not generated during the engraving process, reducing the risk of deformation.

For thicker acrylic, the speed may need to be reduced to ensure the depth and quality of the cut or engraving.

Frequency:

Using a higher frequency (e.g. 10,000 – 20,000 Hz) works best for cast acrylic, while lower frequencies (e.g. 2,000 – 5,000 Hz) can be used for extruded acrylic.

Engrave Acrylic Laser Operation Tips

Before engraving, it is recommended to remove the protective film on the back of the acrylic, but keep the protective film on the front to prevent scratches.

Ensure that the workbench is at an appropriate height to avoid reflections affecting the engraving quality. This can be achieved by raising the acrylic sheet with a support.

Using an air assist system can help cool the material and reduce the impact of smoke and gas on cutting quality

What Is the Best Focal Length for Laser Engraving Clear Acrylic?

General focal length range

For laser engraving transparent acrylic, the focal length is usually between 50 – 70mm. However, this is only a rough range, and factors such as different laser engraving machine models and acrylic material thickness will affect the optimal focal length.

Engraver power and material thickness adjustment

Power factor: If the laser engraving machine has low power, a shorter focal length may be required to concentrate energy to achieve a better engraving effect. For example, for a low-power laser engraver of 10 – 20W, when engraving 2 – 3mm thick transparent acrylic, the optimal focal length may be around 50 – 55mm. For a high-power laser engraver (such as 50 – 100W), the focal length can be appropriately extended to 60 – 70mm, because the high power can still provide enough energy for engraving at a slightly longer focal length.

Material thickness effect: Thinner acrylic materials (such as 1 – 3mm) usually require a shorter focal length, generally 50 – 60mm. This is because thinner materials require more concentrated energy for effective engraving, and a shorter focal length allows the laser beam to focus more tightly on the surface of the material. When the thickness of the acrylic material increases (such as more than 5mm), in order for the laser to penetrate and engrave evenly, the focal length may need to be appropriately extended to about 65-70mm to ensure that the laser energy can act evenly inside the material.

Test method to determine the best focal length

- Use a test paper with a fine grid or pattern to assist in determining the best focal length. Lay the test paper flat on the engraving platform and place the acrylic material on the test paper.

- Start with an estimated focal length, such as 50mm, and perform a simple engraving test, such as engraving a small circle or straight line. Observe the clarity and depth of the engraving, and then gradually adjust the focal length, each adjustment can be 2-3mm.

- When the engraved lines are clearest and the depth is most uniform, this focal length is the value closer to the best focal length.

- In the process of adjusting the focal length, you should also pay attention to keeping other parameters (such as power, speed, etc.) unchanged, so that the best focal length can be accurately tested.

What are the benefits of using air assist when laser engraving acrylic?

Remove molten material and debris:

Air assist can effectively blow away molten material and debris generated during the engraving process, preventing them from accumulating in the cutting area, thereby reducing burn marks and improving cutting quality.

Reduce thermal effects:

By providing a cooling effect, air assist can reduce the risk of overheating of the material, preventing acrylic from deforming or causing unnecessary thermal damage during the engraving process.

Protect the optical lens:

Using air assist can prevent smoke and other contaminants from adhering to the optical lens of the laser, thereby extending the life of the equipment and reducing the frequency of maintenance.

Improve cutting quality:

Since the flow of air helps to keep the cutting edge clean, using air assist can improve the smoothness of the cut surface and reduce the need for post-processing.

Economic benefits:

Compared with other gases (such as nitrogen or oxygen), air is less expensive as an auxiliary gas, which helps to reduce overall processing costs.

How Do Power and Focal Length Affect Acrylic Laser Engraving?

The effect of power on laser engraving acrylic

- Engraving depth: The power directly determines the engraving depth that the laser can achieve on acrylic materials. When the power increases, the energy transmitted to the acrylic by the laser increases, which can increase the amount of material vaporized or melted, thereby deepening the engraving depth.

- This is because higher power can overcome the vaporization threshold and melting threshold of acrylic materials, allowing more material to be removed.

- Engraving speed and quality: Properly increasing the power can allow for increased engraving speed to a certain extent while ensuring engraving quality. If the power is low, in order to achieve a certain engraving depth, the engraving speed needs to be reduced to allow the laser to have enough time to act on the material.

- Detail performance: For the engraving of fine patterns, the power also needs to be carefully controlled. Excessive power may destroy the details of the pattern.

The effect of focal length on laser engraving acrylic

Energy concentration: The focal length determines the energy concentration of the laser on the surface of the acrylic material. When the focal length is accurate, the laser beam can focus into a small spot on the surface of the material, and the energy is highly concentrated.

Uniformity of engraving effect: The appropriate focal length helps to ensure the uniformity of the engraving effect over the entire engraving area. If the focal length is too short, the laser energy is too concentrated on the surface of the material, which may cause the engraving depth in the center of the engraving area to be too deep, while the engraving depth at the edge is insufficient, resulting in unevenness with deep in the middle and shallow at the edge.

Balance between engraving range and depth: The focal length will also affect the balance between engraving range and depth. Although a shorter focal length can concentrate the energy and deepen the depth easily, the engraving range is relatively small; while a longer focal length disperses the energy, the engraving depth becomes shallower, but a larger engraving range can be obtained. In the actual engraving process, it is necessary to select the appropriate focal length according to the size of the engraving pattern and the required depth.

Conculsion

When laser engraving clear acrylic, proper adjustment of power, speed and frequency is the key to ensuring good results. At the same time, choosing the right material type and following operating tips will also significantly improve the engraving quality.