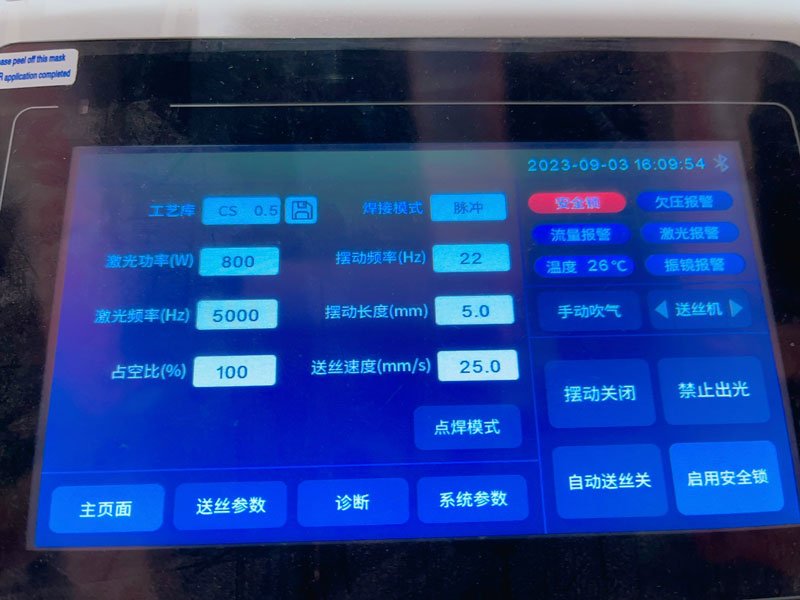

DOWELL light weld 1500 laser machine

lightweld 1500 handheld laser welding system price cost ?

The cost of lightweld 1500 is influenced by several factors including the power of the welding machine, the materials used, the brand, and the budget allocated. Typically, the market price for a lightweld 1500 ranges from US$6,000 to US$10,000. The ipg lightweld 1500 commands a higher price due to its strong brand influence and superior quality.

For further information on lightweld pricing, consider exploring Alibaba or Amazon for a comparison of prices from various manufacturers.