Dowell Bevel Laser Cutting Machine for sale

- Brand:DOWELL LASER

- Power:4000w-30kw

- Cutting angle: 0-45 degrees

- Equipment bed can be customized

- OEM ODM available

- Place of origin: Chinese manufacturer

- Transportation method: Sea freight

Introduction

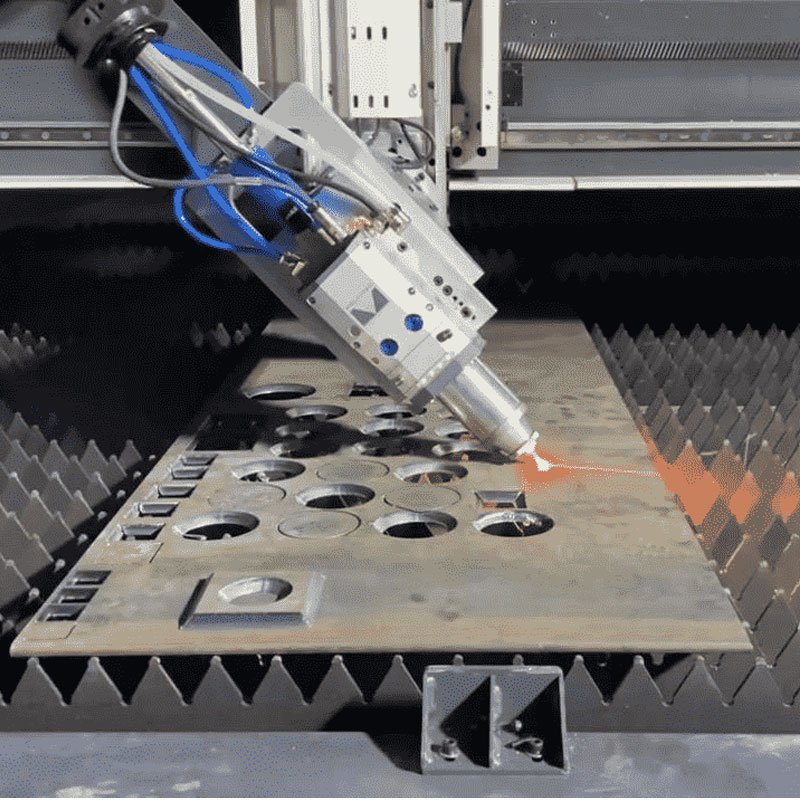

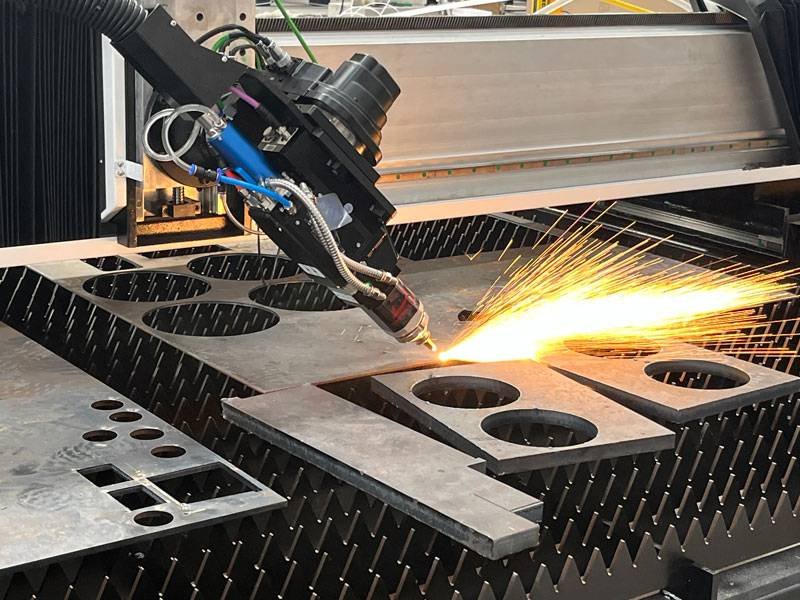

A bevel laser cutting machine is designed to cut materials at different angles, typically ranging from 0 to 45 degrees. Unlike standard laser cutting machines that cut perpendicular to the material’s surface, bevel laser cutters can make angled cuts, which are crucial for creating chamfers, beveled edges, and complex geometrical shapes.

Technical Parameters

- Brand: Dowell Laser

- Power: 3000w-60kw laser cutter

- Working width (mm):3015/4025/6025/8025/12025

- Maximum load weight: 374 lbs.

- X/Y axis single axis maximum positioning speed (m/min): 170

- X/Y axis maximum linkage speed (m/min): 240

- Z-axis travel: 100mm

- Customizable designs

- Maximum positioning acceleration: 2.4G

- Power supply: three-phase 380V/50/60Hz

- Production place: China

- Customizable super large format

Laser Bevel Cutting video

3D 5 Axis Laser Bevel Cutting Machine video

Bevel Tube Fiber Laser Cutting Machine video

Laser Bevel Cutting type

Bevel CNC Fiber laser cutting machine for sale

5 axis laser tube cutting Machine for sale

Advantages of Bevel Laser Cutting Machines

Precision and Accuracy

- Bevel laser cutting machines offer unparalleled precision, allowing for the creation of complex shapes and angles with high accuracy. This precision reduces the need for additional machining and finishing processes.

Versatility

- These machines can cut a wide range of materials, including metals, plastics, and composites. This versatility makes them suitable for various industries and applications.

Efficiency

- The advanced technology used in bevel laser cutting machines ensures fast cutting speeds and high productivity. Automated features further enhance efficiency by reducing manual intervention.

Quality

- The cuts produced by bevel laser machines are clean and smooth, minimizing the need for secondary processing. The high-quality cuts also ensure better fitment and assembly of parts.

Cost-Effectiveness

- While the initial investment in a bevel laser cutting machine may be high, the long-term benefits of increased productivity, reduced material waste, and lower labor costs make them a cost-effective solution for many industries.

Configuration

The cutting head can be swiveled

The cutting head has a large swing angle, and both axes can swing not less than ±50°, which can satisfy bevel cutting at any angle;

Aluminum alloy swing arm

The swing arm is made of high-strength aluminum alloy casting, which is light in weight and has good rigidity to ensure the flexibility of the swing axis during cutting;

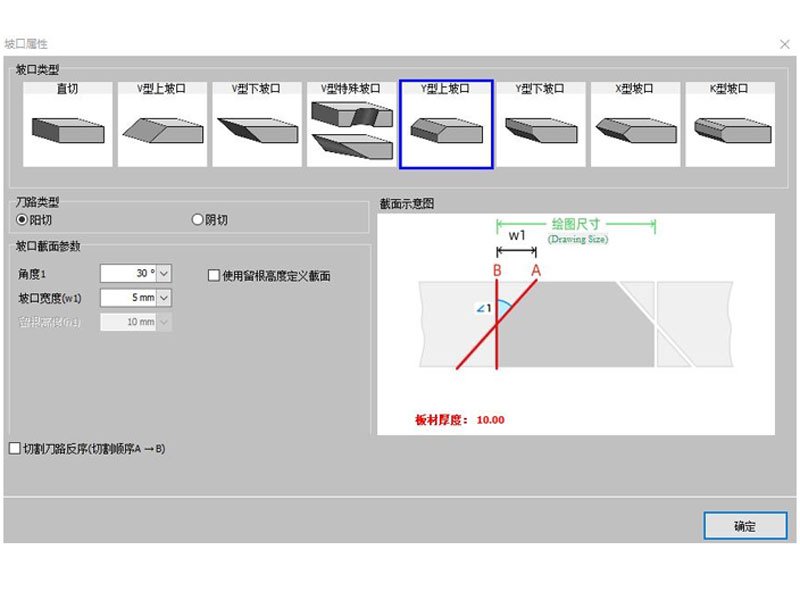

Professional plane groove cutting system

Professional programming nesting software for nesting layout and programming of bevel cutting, easy to operate

laser bevel cutting machine Features

Multi-Axis Control

- These machines are equipped with multi-axis control systems that allow the laser head to move and tilt at various angles. This capability is essential for achieving precise bevel cuts.

Advanced Laser Technology

- Bevel laser cutting machines typically use CO2 or fiber lasers. Fiber lasers are preferred for their efficiency and ability to cut through various materials with high precision.

Dynamic Focus Control

- This feature ensures that the laser beam remains focused on the cutting point, even when the cutting head is tilted. Dynamic focus control is crucial for maintaining cut quality and precision.

Automated Material Handling

- Many bevel laser cutting machines come with automated material handling systems that streamline the process of loading and unloading materials, thus enhancing productivity.

CNC Integration

- Computer Numerical Control (CNC) systems are integrated into bevel laser cutting machines to provide precise control over the cutting process. This integration allows for the automation of complex cutting tasks and ensures repeatability and accuracy.

application

Aerospace

- Creating complex components with precise bevels for structural integrity and aerodynamics.

- Cutting materials such as titanium, aluminum, and composite materials.

Automotive

- Manufacturing parts that require angled cuts for better fitment and assembly.

- Producing components like exhaust systems, chassis parts, and structural beams.

Construction and Shipbuilding

- Cutting structural steel and other materials for building frames, supports, and panels.

- Fabricating parts that need precise angles for assembly and welding.

Metal Fabrication

- Creating beveled edges on metal sheets and plates for various industrial applications.

- Producing parts with chamfers and complex geometrical shapes.

How Much is A Bevel laser cutting machine price

The price of a bevel laser cutting machine is generally around US$ 37155.81-141742.52. The higher the power, the higher the price. This is related to brand awareness, manufacturer’s strength, configuration, power size, etc.

Contact us to get the latest metal pipe laser cutting equipment prices and recommend a suitable pipe cutting machine for you.

FAQ

Bevel cutting machine application

Mainly suitable for carbon steel, stainless steel, titanium alloy, aluminum alloy and other different materials in various fields such as aerospace, automobile

What are the advantages of a groove cutting machine?

The bevel laser cutting head has flexible operation and strong scalability; lightweight design, machine tool load; adopts reliable motor and reducer integrated hollow rotary actuator and stable structural design.

Bevel cutting with laser pipe cutter

- Angle bevel cutting, better splicing effect

- When splicing and welding pipes, in order to achieve seamless jointing of the workpieces, there are certain bevel requirements for the cutting ports. The straight pipe cutting process of the traditional pipe cutting machine has problems such as large gaps, missing arcs and round pipes, etc. Subsequent splicing It is difficult to process and requires beveling again.

- Subsequent processing is easier

- Workpieces cut directly by traditional laser pipe cutting machines will have gaps during splicing. These gaps will cause obvious troubles to subsequent welding. They not only increase the welding workload, but also increase the difficulty of the welding process. Affect product quality.

- Reduce labor and material costs

- The bevel cutting process of the pipe laser cutting machine can achieve zero-gap welding. During the subsequent splicing process, there is no need to process again, which reduces the process and greatly reduces labor and material costs.

Why use ultra large format 10,000-watt bevel laser cutting machine

- Breakthrough processing limits

- Solve the four major problems of low processing accuracy, low efficiency, serious waste, and high cost

- Realize benefits in the construction machinery industry

Traditional bevel cutter VS bevel laser cutting machine

The cutting accuracy and speed of the bevel cutting machine are relatively slow and are suitable for scenes that do not require high cutting accuracy;

The bevel laser cutting machine has high cutting accuracy and speed, and is suitable for scenes that require high cutting accuracy.

What materials does the bevel laser cutter cut?

1. Efficient cutting of thick plate bevels

The bevel supports cutting metal plates with a thickness of about 30mm; compared with the traditional bevel cutting process, the efficiency of lzser cutting bevel plates is greatly improved.

2. Improvement of bevel cutting quality

The three-dimensional five-axis lser cutting head can support 45-degree bevel cutting and forming in one step without the need for secondary processing. The workpiece can be directly used for welding, effectively replacing traditional punching dies and trimming processes, shortening the production cycle and reducing manufacturing costs.

3. Stable production and batch processing

Using lzser cutting equipment for bevel cutting can effectively ensure cutting accuracy, stable cutting quality, and reduce processing errors. It is suitable for batch processing and production of bevel parts.

4. Reduce bevel processing costs

Traditional bevel parts processing requires a lot of manual labor to participate in cutting and grinding; using laser cutting equipment for cutting can help companies effectively reduce labor costs and time investment, thereby solving the problem of difficulty in recruiting workers and reducing production costs.

5.Support multi-type bevel cutting

This kind of bevel laser cutting equipment breaks through the conventional straight cutting method and supports cutting K, V, Y and other types of bevels, saving production processes, reducing welding difficulty, and thus improving sheet metal processing efficiency.