In the ever-evolving field of metal fabrication, innovation reigns supreme as technology paves the way for cutting-edge advances. Enter the revolutionary field of metal fabrication as we delve into China’s remarkable breakthroughs in fiber laser tube cutting technology.

The Evolution of the Metal Processing Industry

The metal fabrication industry has come a long way from its humble beginnings. From manual techniques to the advent of machinery, the industry has witnessed a remarkable evolution. However, it is China’s large tube laser cutting technology that has truly revolutionized metal fabrication. This groundbreaking innovation has transformed the way we shape and manipulate metal, offering unprecedented precision and efficiency.

Traditionally, metal fabrication involves labor-intensive processes such as cutting, bending, and welding. These methods were time-consuming and often resulted in inconsistencies. With the introduction of tube fiber laser cutting technology, the industry experienced a significant shift towards automation and accuracy.

What is Laser Cutting Technology

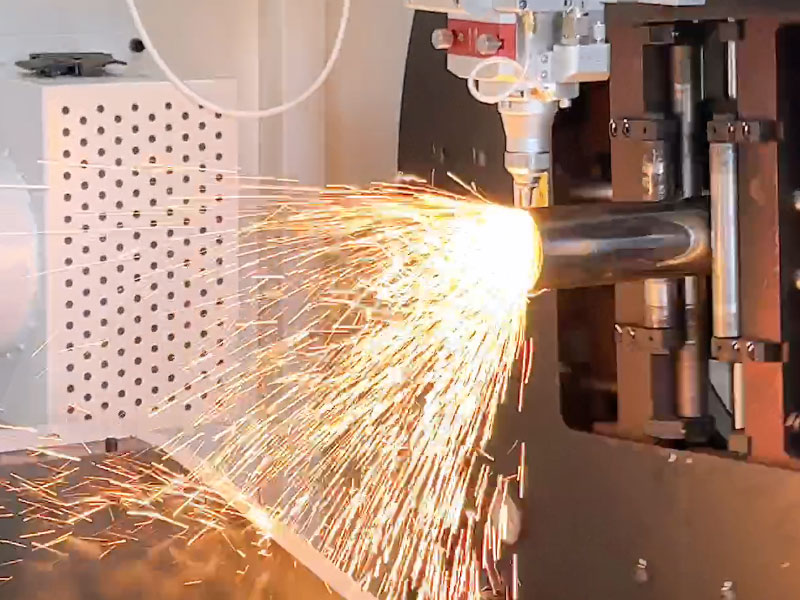

Laser cutting is a technique of making use of a highly powered laser beam to cut through different materials such as metal. The process involves focusing the laser beam on the surface of a material, and then melting or vaporizing it along some predetermined route. Laser cutting has several benefits over conventional methods, among them are accuracy, speed, and versatility.

China’s specialization in large tube laser cutting technology has super-charged the industry by enabling manufacturers with the possibility of extremely complex design work at the highest levels of precision. The utilization of lasers ensures that there is no contact with the material resulting in straight cuts hence minimal chances for destructions or shape-warping.

Advantages of Large Tube Laser Cutting

China’s large tube laser cutting technology offers numerous advantages that have revolutionized metal fabrication processes worldwide:

- Précision: Laser cutting provides unparalleled precision, allowing manufacturers to create intricate designs with exceptional accuracy.

- Efficacité: The speed and efficiency of large tube laser cutting technology significantly reduce production time and costs.

- Polyvalence: Laser cutting can be applied to various types of metals, including stainless steel, aluminum, and copper.

- La flexibilité: The non-contact nature of laser cutting enables manufacturers to work with complex shapes and designs.

China’s Pioneering Role in Metal Fabrication

China has emerged as a global leader in metal fabrication, thanks to its pioneering role in large tube laser cutting technology. The country’s investment in research and development has led to groundbreaking innovations that have transformed the industry.

Chinese manufacturers have harnessed the power of large tube laser cutting technology to create intricate architectural structures, automotive components, and even aerospace parts. The precision and efficiency offered by this technology have made China a preferred destination for metal fabrication projects worldwide.

Precision and Efficiency in Large Tube Laser Cutting

The precision and efficiency of China’s large tube laser cutting technology are unparalleled. With the ability to cut through thick metal tubes with utmost accuracy, manufacturers can achieve intricate designs that were once considered impossible.

This level of precision is crucial in industries such as aerospace and automotive, where even the slightest deviation can have significant consequences. Large tube laser cutting ensures that every component meets the strictest quality standards, guaranteeing optimal performance and safety.

Applications of Large Tube Laser Cutting Technology

The applications of large tube laser cutting technology are vast and diverse. From architectural marvels to industrial machinery components, this innovative technique has found its way into various industries:

- Architecture: Large tube laser cutting enables the creation of complex metal structures for iconic buildings and landmarks.

- Automotive: This technology is used to fabricate precise components for vehicles, ensuring optimal performance and safety.

- Aérospatial: Big tube laser cutting plays a crucial role in manufacturing aerospace parts with intricate designs and strict tolerances.

- Industrial Machinery: Manufacturers rely on large tube laser cutting to produce high-quality components for machinery and equipment.

Overcoming Challenges in Large Tube Laser Cutting

Large tube laser cutting technology has many advantages; however, it also comes with its fair share of problems. One major problem is that it requires skilled operators to program and operate the cnc laser tube cutting machines effectively.

For a remedy to this challenge, China has made substantial investments in training programs and educational initiatives so as to develop a highly trained workforce able to exploit the full potential of large tube laser cutting technology. This enables manufacturers to optimally utilize this novel technique.

Future Prospects and Innovations in Metal Fabrication

The future of metal fabrication looks promising, with continuous advancements in large tube laser cutting technology. As manufacturers push the boundaries of what is possible, we can expect even greater precision, efficiency, and versatility.

Innovations such as real-time monitoring systems, artificial intelligence integration, and enhanced automation are set to revolutionize metal fabrication processes further. These advancements will not only streamline production but also open up new possibilities for design and creativity.

Global Impact of China’s Large Tube Laser Cutting Technology

The impact of China’s large tube laser cutting technology extends far beyond its borders. Manufacturers worldwide are embracing this innovative technique to enhance their capabilities and stay competitive in the global market.

China’s expertise in large metal tube laser cutter has led to collaborations with international partners, driving innovation on a global scale. The exchange of knowledge and resources has resulted in remarkable advancements that benefit industries across continents.

Conclusion:

China’s large tube laser cutting technology has revolutionized the metal fabrication industry, offering unparalleled precision, efficiency, and versatility. As this innovative technique continues to evolve, we can expect even greater advancements that will shape the future of metal fabrication.