Are you looking for the best fiber laser cutting machines for industrial applications? I will help you determine if you really need fiber optic laser cutting machines. This article will introduce the most affordable fiber laser cutter on the market in detail, hoping to help you make the right choice.

I recommend the 3015 1000w fiber metal laser cutting machine to most users. This product is relatively affordable and has a high usage rate in the industrial market, and is available in different sizes to fit your workspace.

What is the Best Fiber Laser Cutter?

Fiber laser cutting machine is a high-precision and high efficiency cutting equipment that uses a high-energy beam generated by a fiber laser to cut materials.

The best fiber laser cutting machine usually has the following characteristics:

- High power and high precision: high quality fiber laser cutting machines are usually equipped with high-power lasers (such as 1kW to 10kW), which can handle thicker materials and maintain high precision in the cutting of thin materials.

- Stable performance: using advanced fiber laser technology to ensure stability and consistency during the cutting process. High quality fiber lasers have longer service life and lower maintenance requirements.

- Efficient cutting speed: high quality fiber laser cutting machines can cut at a higher speed while ensuring cutting quality, greatly improving production efficiency.

- Wide range of material adaptability: capable of cutting a variety of materials, such as stainless steel, carbon steel, aluminum, copper and other metal materials, and performs well on materials of different thicknesses.

- Advanced software control system: equipped with an intelligent CNC system, the operation interface is friendly, easy to program and adjust, and supports precision cutting of complex graphics.

The Best CNC Fiber Laser Cutting Machines Brand in China – Ranked

1.Bodor Fiber Laser Cutter P-Series 3015

Advantages:

- High cost performance, suitable for small and medium-sized enterprises.

- Equipped with intelligent operating system, easy to use.

- High-efficiency laser source, guaranteed cutting quality.

- Stable mechanical structure, durable and reliable.

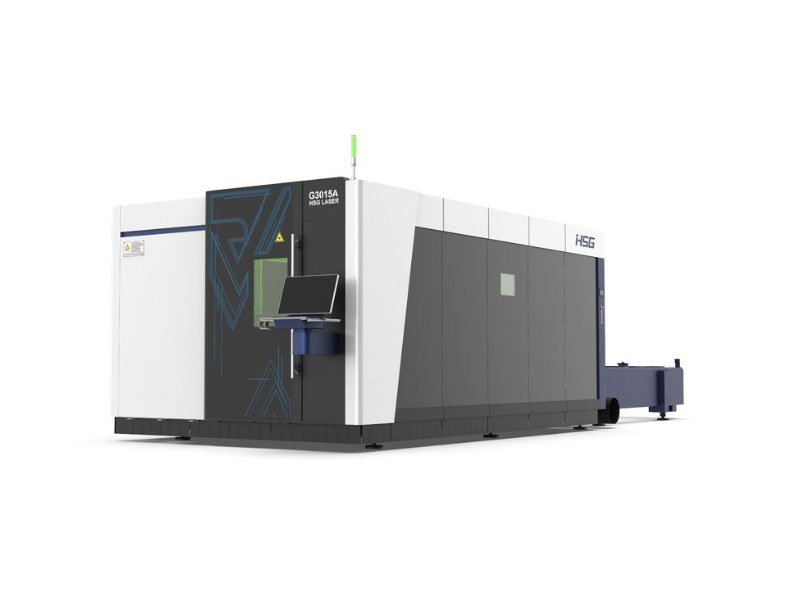

2.HSG Laser G3015A

Advantages:

- Affordable price, low operating cost.

- Suitable for high-precision cutting of various metal materials.

- Equipped with intelligent operation interface, easy to operate and maintain.

- Fast cutting speed, improve production efficiency.

3.GWEIKE LF3015GA

Advantages:

- High cost performance, reliable quality.

- Equipped with automatic focusing system to improve cutting efficiency.

- Support cutting of various metal materials, widely used.

- Low maintenance cost and long

4.SENFENG SF3015G

Advantages:

- Affordable price, suitable for small and medium-sized enterprises.

- Compact structure, small footprint.

- High-efficiency laser cutting, smooth cutting edge.

- Intelligent control system, simple operation.

5.DOWELL LASER DW3015

Advantages:

- High cost performance, suitable for enterprises with limited budget.

- Adopt high-quality fiber laser source, good cutting effect.

- High stability, suitable for long-term continuous work.

- Easy maintenance, reducing the cost of use.

How to Choose a Best CNC Fiber Laser Cutting Machine?

- Power requirement: Select the appropriate laser power according to the type and thickness of the material to be cut. For cutting thick and heavy metals, a high-power laser needs to be selected, while for thinner materials, a lower-power laser can be selected to save costs.

- Cutting speed and accuracy: Different models of fiber laser cutting machines have different cutting speeds and accuracy. It is necessary to select equipment that can ensure both cutting quality and production efficiency according to actual production needs.

- Brand and after-sales service: Choosing a fiber laser cutting machine from a well-known brand can usually ensure the quality and stability of the equipment. At the same time, good after-sales service can also provide guarantees in equipment maintenance and troubleshooting.

- Software functions: Understand the functions and ease of use of the control software equipped with the equipment to ensure that operators can quickly get started and make full use of the software functions to improve production efficiency.

- Cost and budget: When choosing equipment, it is necessary to consider the purchase cost, operating cost and maintenance cost of the equipment. Choose the most cost-effective fiber laser cutting machine according to the budget.

Can I Buy a Second-Hand Fiber Laser Cutting Machine?

Equipment status and service life:

Check the equipment’s usage history, operating hours, and maintenance records to ensure that the equipment is still in good working condition and that its remaining service life is sufficient to meet production needs.

Performance and technical support:

Confirm whether the performance of the second-hand equipment can meet current production requirements, and understand whether the supplier provides technical support and maintenance services to deal with possible problems with the equipment.

Upgrade and compatibility:

Understand whether the equipment can be upgraded to adapt to possible changes in production needs in the future. At the same time, ensure that the equipment’s parts and consumables are easily available in the market for daily maintenance and repair.

Price and cost-effectiveness:

Comprehensively evaluate whether the price of the second-hand equipment is reasonable, compare it with the performance gap of the new equipment and the possible maintenance costs, and ensure that the second-hand equipment finally selected has a high cost-effectiveness.

With the above considerations, buying a second-hand fiber laser cutting machine can be a cost-effective option, but it is necessary to fully understand the specific situation of the equipment before purchasing to ensure that it can meet production needs and maintain stable working performance.

Article associé

- Top 10 High Quality Laser Cutter Factories in the World

- Top 10 Jinan Fiber Laser Cutting Machine Fabricants

- Ultimate Guide To Choosing A Fiber Laser Cutting Machine Supplier

- Industrial Laser Cutters: A Comprehensive Guide

- Chine Wholesale 1530 Fiber Laser Cutting Machine Factories

- Top 10 Chine Fiber Laser Cleaning Machine Fabricants

- 2024 Top 10 Best Laser Cutting Machine In Chine