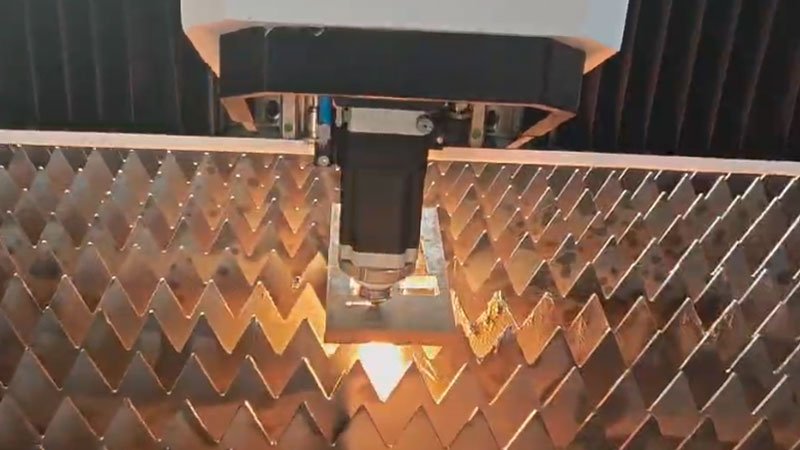

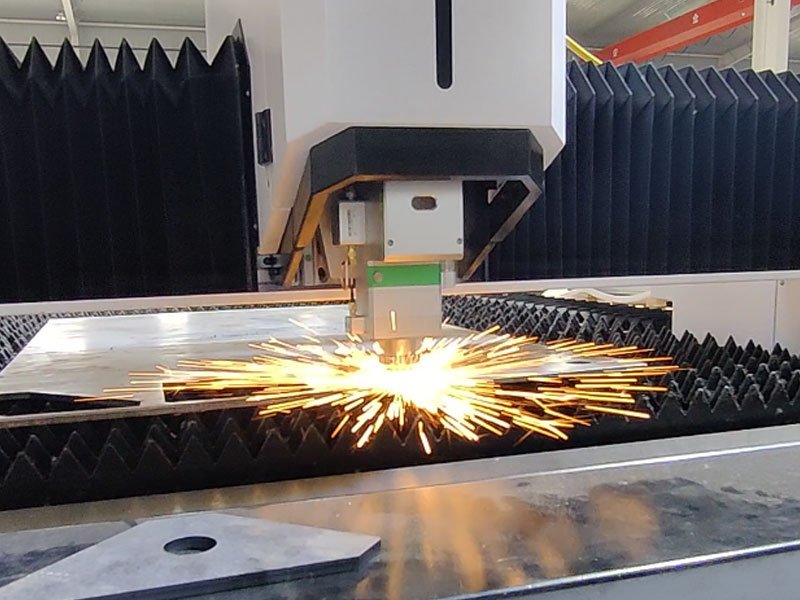

As a manufacturer of Faserlaser-Schneidemaschinen, we understand that the quality of laser cutting is paramount to our customers’ satisfaction and success. Whether you are in the automotive, aerospace, or metal fabrication industry, achieving precise, clean cuts is critical to maintaining high standards in your production process.

In this blog post, we will delve into the factors that influence laser cutting quality and how our fiber laser cutting machines are designed to meet and exceed these demands.

In today’s competitive manufacturing landscape,

laser metal cutting machines

- Präzisionhave become indispensable tools for businesses looking to enhance precision, speed, and efficiency in their operations. However, one of the most crucial factors in deciding whether to invest in this technology is understanding the true cost of a laser metal cutting machine.

- This comprehensive guide will delve into the various aspects of laser metal cutting machine costs, helping you make an informed decision for your business.Initial Purchase Price: More Than Just a Number

- ConsistencyHidden Costs: What Lies Beneath the Surface

- 1. Installation and Setup2. Operating Costs

3. Consumables and Spare Parts

- 4. Software and Upgrades

- Factors Affecting Long-term Costs1. Material Types and Thicknesses

- 2. Production Volume3. Operator Skill Level

- Strahlqualität

- 4. Maintenance PracticesCost Comparison: Laser Cutting vs. Traditional Methods

- Laser Cutting vs. Plasma CuttingLaser Cutting vs. Waterjet Cutting

- Return on Investment (ROI): Justifying the Cost

- Cost-Saving Strategies for Laser Cutting OperationsFinancing Options: Making the Investment Manageable

- Future-Proofing Your InvestmentConclusion: Balancing Cost and Value

- considering the laser sheet metal cutting machine cost, the first figure that comes to mind is usually the initial purchase price. However, this is just the tip of the iceberg. The price of laser cutting machines can vary widely, typically ranging from $100,000 to over $1,000,000, depending on several factors:

- Assist Gas: Higher wattage machines generally cost more but offer increased cutting capabilities.

- Cutting Area: Larger cutting beds allow for bigger workpieces but come at a premium.

- Technology Type

- Materialtyp: Fiber, CO2, and other laser types have different price points.

- MaterialstärkeBrand and Origin

: Well-known brands and machines from certain countries may command higher prices.

- : Automation, advanced software, and other extras can significantly increase the cost. Hidden Costs: What Lies Beneath the Surface

- Beyond the sticker price, several hidden costs can impact your total investment: Professional installation is crucial for optimal performance and safety. Costs can include:

- Anpassbare Einstellungen Site preparation

- Electrical work Ventilation systems

- Training for operators These expenses can add 5-15% to the initial machine cost.

Abschluss

Electricity