Many customers will ask about the power when consulting the Laser-Rohrschneidemaschine. This article will comprehensively introduce you to the information about the 1kw fiber laser pipe cutting machine. I hope it will be helpful to you.

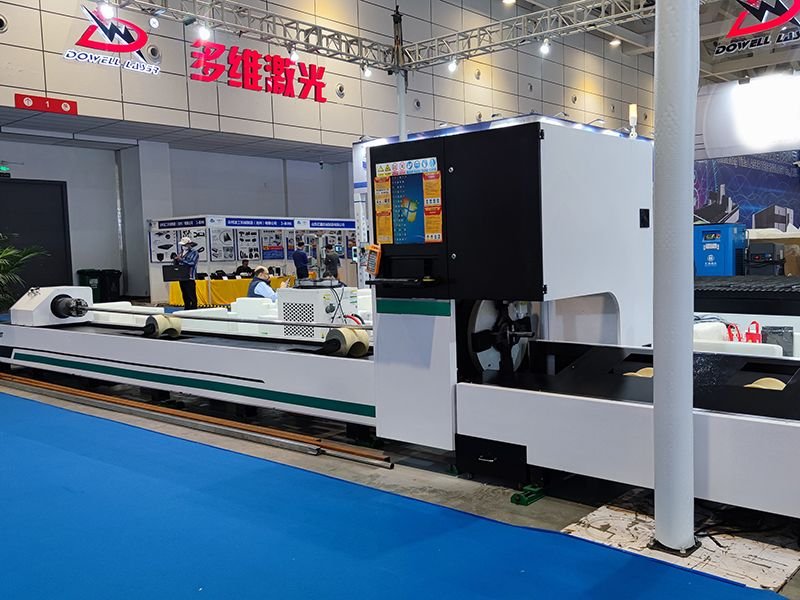

1kw fiber laser pipe cutting machine composition

The laser pipe cutting machine system generally consists of a fiber generator, pipe cutting machine cutting head, (external) beam transmission component, workbench (machine tool), CNC cabinet, chiller and computer (hardware and software).

Benefits of Metal Pipe Laser Cutting Machine

Accuracy

1000 watts of power helps deliver smooth, clean cuts on thick stainless steel pipe, ensuring impeccable edges – for industries with stringent measurement requirements.

Geschwindigkeit

Laser machines operate much faster than traditional cutting methods such as sawing or plasma cutting. Increased efficiency means shorter production times, resulting in faster turnaround and increased productivity.

Improve production efficiency and reduce costs

Streamline processes by eliminating manual labor intensive tasks. Automation minimizes errors, guarantees consistent results, and improves operational efficiency while reducing labor costs.

1000w Laser Pipe Cutting Machine Cuts Multi-Thick Stainless Steel Pipes

| Wall Thickness | Pipe Diameter |

|---|---|

| 0.5 mm | 20 mm – 60 mm |

| 1.0 mm | 20 mm – 100 mm |

| 1.5 mm | 20 mm – 120 mm |

| 2.0 mm | 20 mm – 150 mm |

Top 1kw Fiber Laser Pipe Cutting Machine Manufacturers

Here are some manufacturers of Fiber Laser Pipe Cutting Machines:

| Hersteller | Location | Key Features | Anwendungen |

|---|---|---|---|

| Hans Laser | Chine | High precision, high efficiency, high stability | Aerospace, automotive, machinery, electronics |

| Raycus-Laser | Chine | High performance, high cost-effectiveness | Global market |

| Maxphotonics | Chine | High speed, high precision | Sheet metal processing, machinery Herstellung, automotive Herstellung |

| Goldener Laser | Chine | High reliability, high adaptability | Aerospace, military, electronics |

| HGTECH | Chine | High precision, high efficiency, high stability | Aerospace, automotive, machinery, electronics |

| Bosel Laser | Chine | High speed, high precision | Sheet metal processing, machinery Herstellung, automotive Herstellung |

| Jaguar Laser | Chine | High reliability, high adaptability | Aerospace, military, electronics |

| IPG Photonik | USA | High performance, high cost-effectiveness | Global market |

| Kohärent | USA | High precision, high efficiency, high stability | Aerospace, automotive, machinery, electronics |

| Prima Power | Italy | High flexibility, high automation | Aerospace, automotive, machinery, electronics |

These manufacturers are known for producing high quality CNC laser tube cutting machines that are used in various industries for precise and efficient cutting of pipes and tubes.

How Much Does a 1kw Fiber Laser Pipe Cutting Machine for Sale Cost?

There is no specific price for a 1000w fiber laser pipe cutting machine, as it depends on the reputation of the brand, machine specifications, additional features and after-sales support. On average, you can purchase a high quality 1000w CNC tube laser metal cutting machine at $20,000 to $200,000.

It is important to consider your requirements and budget when selecting a CNC laser tube cutting machine. However, cost should not be the only determining factor. Instead, it would be best if you found a machine with the right combination of price and performance that will ensure long term return on investment.

Pipe Fiber Laser Cutting Machines Applications

Automobilindustrie: Used for cutting exhaust pipes, chassis parts, and other metal parts in the automotive industry. The machine’s precision and speed ensure high-quality cuts for efficient production.

Baugewerbe: From structural components to piping systems, the construction industry plays a vital role. They can easily cut pipes of different materials and sizes, making them an essential tool for construction projects.

Möbelherstellung : Creating intricate designs and patterns on metal pipes. This allows unique custom furniture to stand out in the market.

Luft-und Raumfahrtindustrie: Used to cut pipes on aircraft frames, engine components, and other critical components with extremely high precision.

Safety Guidelines When Operating a Pipe Fiber Laser Cutting Machine

- While operating the machine, make sure you wear suitable personal protective equipment (PPE), which includes safety glasses, gloves, and ear defenders.

- Ensure that the workplace is fully ventilated to avoid fume exposure from the cutting process.

- Periodically inspect and maintain machines based on manufacturer’s guidelines for best performance and to reduce risks.

- Train your operators on proper maintenance procedures and provide them with regular training whenever necessary. By adhering to these safety regulations you can make a secure workspace while getting the most out of your pipeline fiber laser cutter.