large format bed laser cutter machine for sale

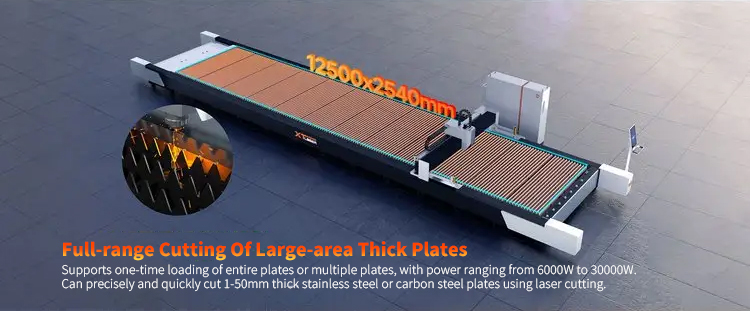

Large format metal laser cutting machine, large workbench, suitable for laser equipment above 3000w, the format can be customized.

The cutting speed of big laser cutting machine is twice that of carbon dioxide laser cutting machine with the same power.

Power:3000w 6000w 10kw 12kw 15kw 20kw 30kw 60kw

Einführung

The large bed laser cutter is suitable for cutting large-format metal sheets in the industrial market, saving time and improving work efficiency. It adopts gantry structure machine tools, aluminum alloy beams, high-precision grinding helical gear racks, high-precision linear It is a high-tech product that uses a combination of professional cutting CNC systems. In terms of cutting, large-format laser cutting machines have the characteristics of fast cutting speed and low maintenance costs.

large bed laser cutter video

14031 large format laser cutting machine

12000w universal large laser cutter

Paramètres techniques

- Marke: Dowell Laser

- Leistung: 3000 W – 60 kW

- Working width (mm):12000*2500

- Workbench load: 10000kg

- Positioning accuracy: ±0.03mm/m

- Repeat positioning accuracy: ±0.02mm/m

- Maximum speed: 120m/min

- Anpassbare Designs

- Maximum acceleration: 1.2G

- Stromversorgung: dreiphasig 380 V/50/60 Hz

- Lieu de production : Chine

- Anpassbares Supergroßformat

Features & Advantages

- Double wire feed laser welding machine

- 3KW Double wire feed laser welding machine

- Laser power: 3000W

- Fiber Length :Standard10m Maximum 15m

- Laser Wave Length :1070 Nm

- A scrap cart is installed at the bottom of the cutting area and can be pulled out regularly.

Laser Head: Wobble Combined Laser Welding & Cleaning Head

The 3kw Dual Wire Feeding Laser Welding Machine is a powerful handheld fiber laser welding machine that combines laser welding and wire feeding functions in one portable device. The dual wire feeding system can send two wires at the same time. Extensive material compatibility, welding up to 12mm (1/2 inch) thick metal laser cutting, weld cleaning, fiber laser cleaning and other integrated functions.

A double wire feed laser welding machine is a type of laser welding equipment designed to use two separate wires simultaneously during the welding process. This configuration enhances the welding performance and efficiency for specific applications.

benefits of double wire feed laser welding machines

1. The weld seam is more uniform: The power output of swing laser welding is relatively uniform, making the shape of the molten pool more symmetrical. After welding, the weld surface is smoother and of better quality.

2. Faster welding speed: Oscillating laser welding can increase the welding speed and improve production efficiency.

3. During the swing welding process, the laser stirs the molten pool, which also increases the shape and diameter of the laser hole. The keyhole and molten pool become stable, which is conducive to the discharge of keyhole gas and reduces the generation of pores. Compared with single laser, they all have different degrees of inhibition. Sequential circular, counter-circular, parallel and vertical trajectories have a more obvious inhibitory effect on stomata, among which vertical stomata have the lowest rate.

Welding system: Touch screen control panel

Line width:

Contact us to get the latest Welding speed range:0~120 mm/s Welding thickness recommendations :0.5-4mm

FAQ

Welding gap requirements: ≤0.5mm

Working environment temperature:15~35 ºC

Working Voltage: AC380V, 50/60Hz, three phases

Double swing laser welding features:

Enhanced Deposition Rate: By feeding two wires at once, the deposition rate is increased, allowing for faster welding speeds and higher productivity compared to single wire feed systems .

Improved Weld Quality: The use of double wire feed can improve the mechanical properties and quality of the weld by ensuring a more uniform and stable arc, leading to better control over the weld pool and reduced defects such as porosity and cracking .

Versatility: This type of welding machine can be used for a variety of materials and thicknesses, making it suitable for applications in industries like automotive, aerospace, shipbuilding, and heavy machinery where strong and precise welds are required .

Cost-Effective: Although the initial investment may be higher, the increased efficiency and reduced need for rework or repairs can result in long-term cost savings. The machine's ability to handle more complex welding tasks also adds value by expanding the range of possible applications .

Automation and Integration: Double wire feed laser welding machines can often be integrated with robotic systems, enhancing automation and reducing the need for manual intervention. This can lead to more consistent results and further improvements in productivity.

Fiber Laser source

Photoelectric conversion rate is greatly improved, laser power is enhanced, has better welding effect, can according to the needs of customers with different configurations to meet customer needs.

Portable single wobble handheld welding head

Supports Dual & single wire feeding, Light shape, economic deign, instead of fixed weling head, it offers so much welding convenience for welding big, or heavy or complex structure articles.

laser welding system

The human-machine interface mode is easy to operate. The touch screen realizes powerful software functions and can edit and remember functions and welding widths of workpieces. It solves the shortcomings of small laser welding spots and provides better welding shapes.

Double wire feed system