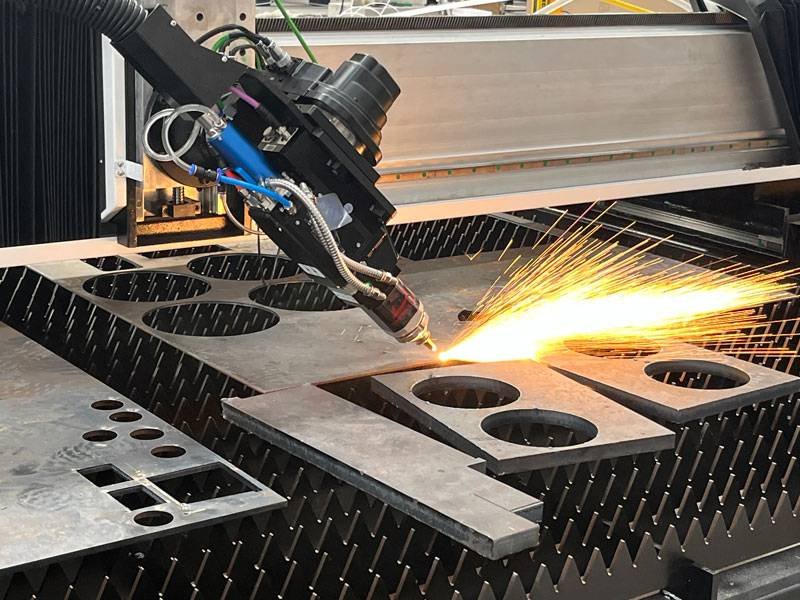

Laser cutting machines play a vital role in modern manufacturing. They are favored by business owners for their high precision and high speed. They are widely used in metal processing, automobile manufacturing, aerospace and other fields in the industrial market.

In these applications, laser cutting machine rate is one of the important factors affecting production efficiency and cost. This article will explore the rate indicators, influencing factors, comparison of different types of laser cutting machines, and technologies to improve the rate of laser cutting machines.

What is Laser Cutting Machine Rate?

The term “laser cutting machine rate” refers to the speed at which a laser cutting machine can cut through materials. It’s typically measured in units such as millimeters per minute (mm/min) or inches per minute (IPM). The cutting rate plays a significant role in determining how fast projects can be completed and how efficient the overall production process is.

The faster the machine can cut, the quicker a manufacturer can turn raw materials into finished products. However, high speed isn’t always ideal if it compromises quality or precision. Hence, understanding the balance between speed and quality is crucial in laser cutting operations.

Factors That Affect Laser Cutting Machine Rate

Materialtyp

Different materials respond to laser cutting in distinct ways. For instance, metals like aluminum and steel often require slower cutting speeds compared to thinner, softer materials like plastic or wood. Here’s a brief overview:

- Metalle: Generally slower due to their density and heat dissipation characteristics.

- Plastics/Acrylics: Faster to cut but require careful adjustments to avoid melting.

- Holz: Cuts quickly, but the rate can depend on moisture content and density.

Materialstärke

The thicker the material, the slower the cutting rate. Thicker materials require more energy to penetrate, reducing the overall speed. For example, cutting through a thin sheet of stainless steel will be much faster than cutting through a thick metal plate.

Laserleistung und -typ

The type and power of the laser used in a machine have a significant impact on the cutting speed.

- CO2 laser : commonly used for non-metallic materials such as wood, plastic and paper. Its cutting speed is generally between 20-100 mm/s, suitable for large area cutting.

- Fiber laser : suitable for metal materials, especially thin metals. Its cutting speed can reach 1000 mm/s, with high efficiency and excellent cutting quality.

- Laser Wattage: Higher wattage increases cutting speed, but it can also lead to higher energy consumption.

Assist Gas (Oxygen, Nitrogen, Air)

The type of assist gas used during laser cutting can influence the rate. For example:

- Oxygen: Promotes faster cutting but may compromise edge quality due to oxidation.

- Nitrogen: Slower but provides cleaner cuts with no oxidation, particularly for metals.

- Air: Can be used for some materials and can strike a balance between speed and quality.

Beam Quality and Focus

A laser’s beam quality and its focus also significantly impact the cutting speed. A well-focused beam can cut materials faster because it concentrates energy on a smaller area, creating a sharper and more efficient cut. Regular maintenance to ensure optimal beam quality is key to maintaining high cutting rates.

Main Speeds that Affect Laser Cutting Machines

Schneidgeschwindigkeit: refers to the speed at which the laser beam moves on the surface of the material, usually expressed in millimeters per second (mm/s).

Moving speed: refers to the speed at which the laser cutting machine moves during the cutting process, including the movement of the laser head and the feed speed of the material.

Acceleration: refers to the acceleration required for the laser cutting machine to reach the maximum speed during the cutting process, usually expressed in g (gravitational acceleration).

Slewing speed: In some applications, the laser cutting machine may need to rotate the cutting head, and the slewing speed refers to the speed at which the cutting head rotates.

Types of Laser Cutting Machines and Speeds

CO2-Laser

CO2 lasers are typically slower when cutting metals but are highly efficient for non-metal materials. The speed varies depending on material thickness, with average rates ranging from 10 mm/sec for thick metals to 200 mm/sec for plastics or thin materials.

Fiber Lasers

Fiber lasers are faster, especially with metals like stainless steel or aluminum. On average, fiber lasers can cut materials at speeds of 20-50 mm/sec for metals and even faster for thinner materials.

Nd Lasers

Although less common, Nd lasers are used in certain industrial applications. These lasers are highly effective for precision cutting, but their speeds are generally slower than fiber lasers.

How to Increase the Speed of Laser Cutting Machine

High power laser: Using higher-power laser can significantly increase the cutting speed, especially when processing thick materials.

High speed CNC system: Using more advanced CNC system, it can quickly calculate and adjust the cutting path to improve overall efficiency.

High speed cutting head: Design a lighter and more efficient cutting head to reduce movement resistance and increase movement speed.

Auxiliary technology: Combining auxiliary cutting technologies such as water jet and plasma can improve cutting efficiency in some cases.

Optimal Cutting Rate for Different Applications

Metal Cutting

When cutting metals like stainless steel or aluminum, fiber lasers are the go-to option due to their higher speeds. A typical fiber laser can cut through 1mm thick stainless steel at a speed of 30-40 mm/sec, while 3mm aluminum might be cut at a speed of 10-15 mm/sec.

Non-Metal Materials

Non-metals, such as acrylics, plastics, or wood, can be cut much faster. CO2 lasers are widely used for these materials, with speeds reaching up to 200 mm/sec for thin acrylic sheets.

Precision vs. Speed

There’s always a trade-off between speed and precision. Cutting at maximum speed may reduce the quality of intricate designs, especially when fine details or tight tolerances are required. For complex designs, operators often reduce the cutting rate to ensure high-quality results.

How to Choose a CNC Laser Cutting Machine Based on Speed

When selecting a laser cutting machine, it’s essential to consider not just the speed but the type of material and precision required. For businesses working primarily with metals, a fiber laser offers the best combination of speed and efficiency. For non-metals, CO2 lasers provide excellent speed at a more affordable price.

Abschluss

The rate of a laser cutting machine is a key factor affecting production efficiency and cost. Drive further development in the manufacturing industry by understanding the factors that affect cutting speed, such as material type, thickness, and laser power. Whether you are cutting metal or non-metal, the right balance between speed and precision is always the key to maximizing performance.