We Build Your Dream

Dowell Laser will create greater laser processing value for you, not best, only better!

Or You Can Use Font Awesome Icons

Customize It The Way You Want!

- Lottie Animations

- Font Awesome Icons

- Upload a Custom Image

Employees

Events

Projects

Followers

Box with icon hover Style

Insert your Icon box with hover style and this widget will show exactly how you want it.

Brief Introduction

One-stop metal forming equipment vonder and supplier

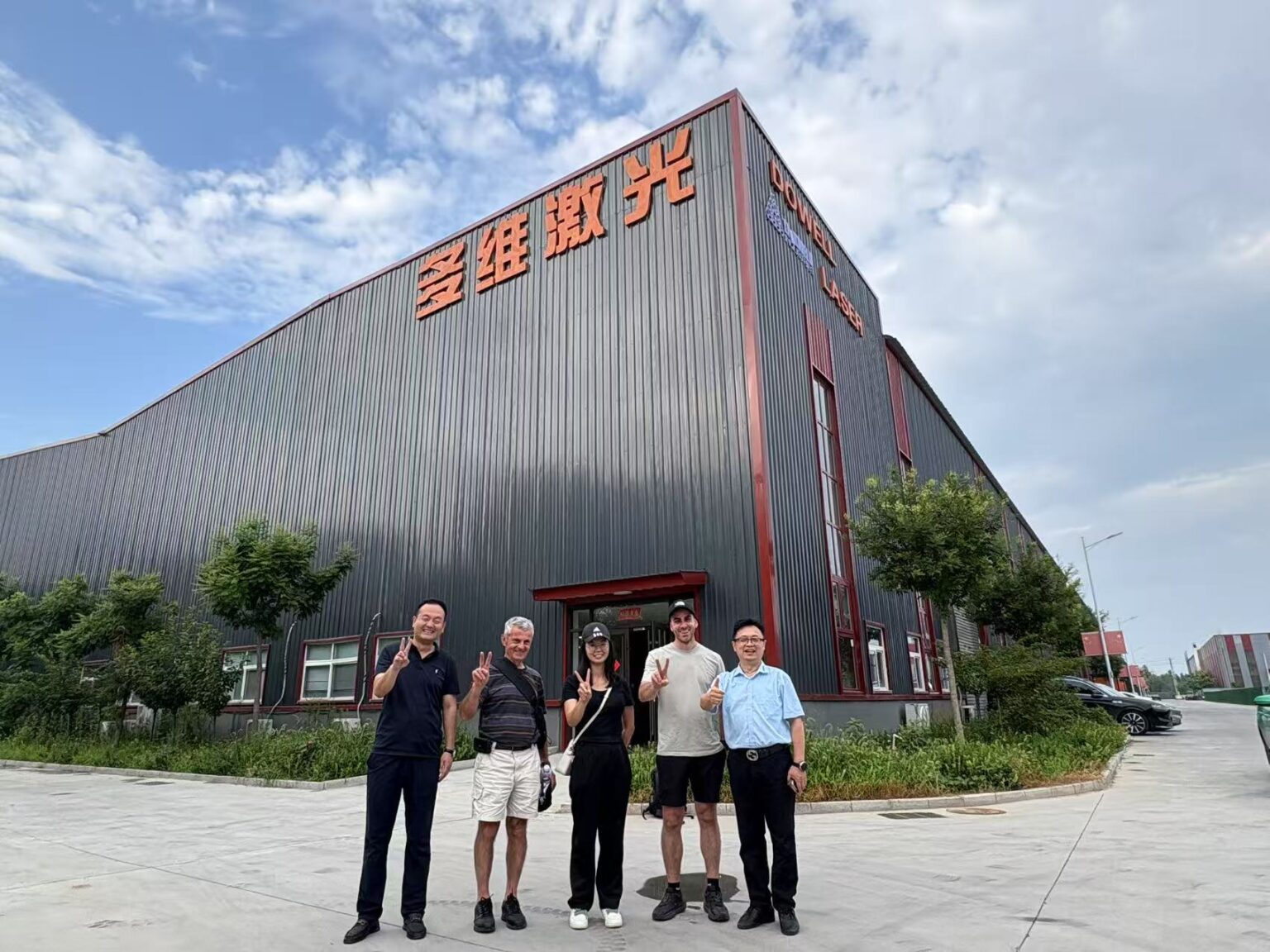

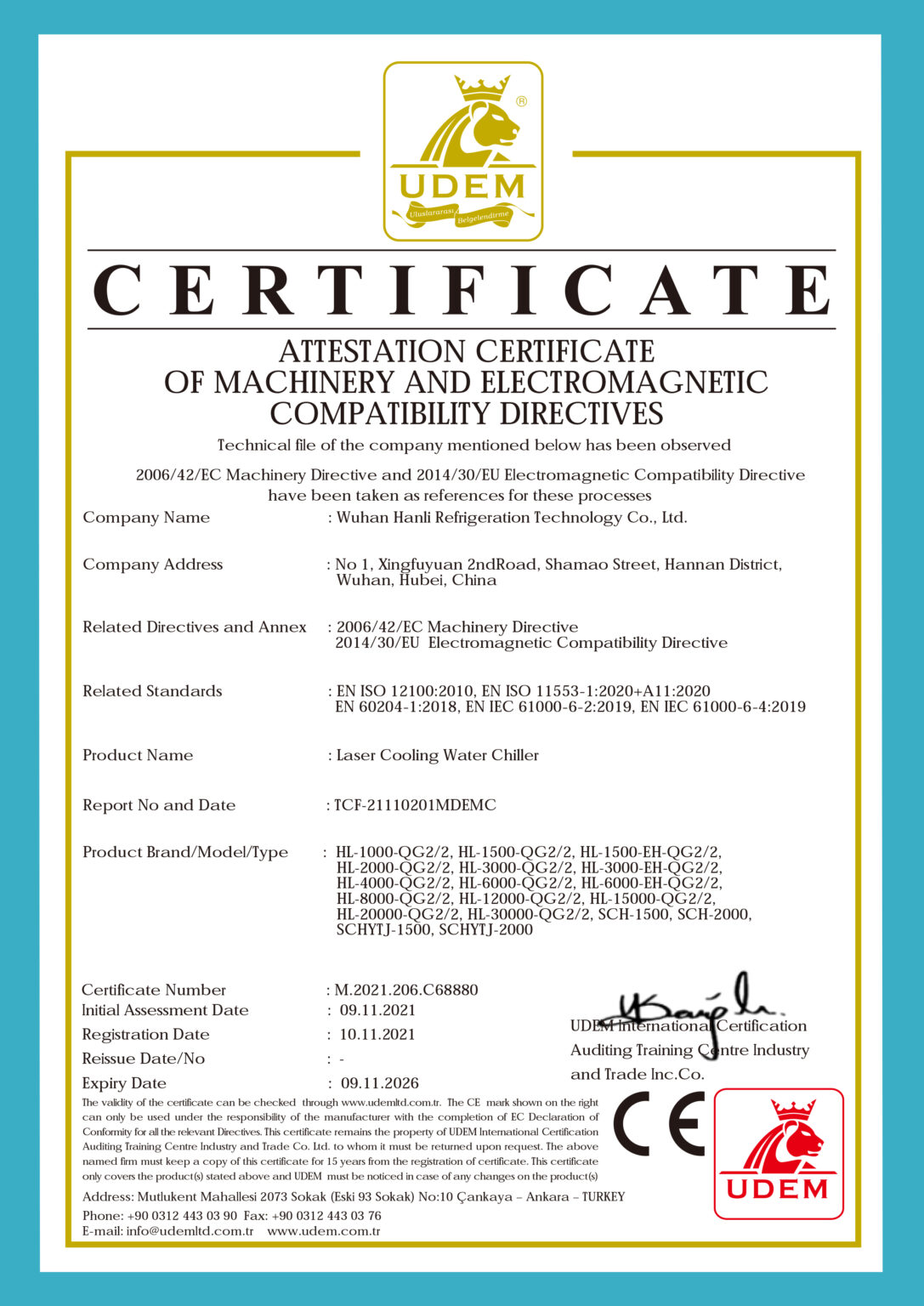

Jinan Dowell Optoelectronic Equipment Co., LTD., after 15 years of professional commitment to optical fiber laser cutting machine, laser pipe cutting machine, laser welding machine and other laser cutting equipment production, research and development, sales work, to provide one-stop laser equipment solutions, is one of the domestic industry with few independent research and development capabilities, the company’s whole series of products have passed CE, FDA and other international certification.

Dowell Laser’s existing technical personnel more than 130+ research and development staffs, and 20, 5000 square meters of modern factory building, located in convenient transportation, Shandong province, Jinan City, and has set up in Guangzhou, Shanghai, Beijing, Zhejiang, Fujian and other places with more than 20 distribution, in more than 30 countries and regions set up agents, products are exported to the United States, Russia, Germany, Turkey, southeast Asia, more than 60 countries and regions. The company fully absorbs the advanced ideas in the international laser field and independently develops a series of laser cutting products. High quality is our pursuit, advanced manufacturing technology, large-scale production, high standards of testing, perfect after-sales service, has won the support and trust of the majority of customers, “customer first, reputation first” is the highest faith that we have always pursued, Dowell laser is willing to work with all over the world, businessmen of all countries to create a brilliant tomorrow!

Our Years Of Journey: A Path Of Growth & Innovation

Establishment and Development

In 2010, Dowell Laser was established in Jinan City.

In 2012, obtained the BACL certification certificate issued by an American laboratory.

In 2013, passed the EU CE certification, and its equipment officially entered the mainstream European and American markets.

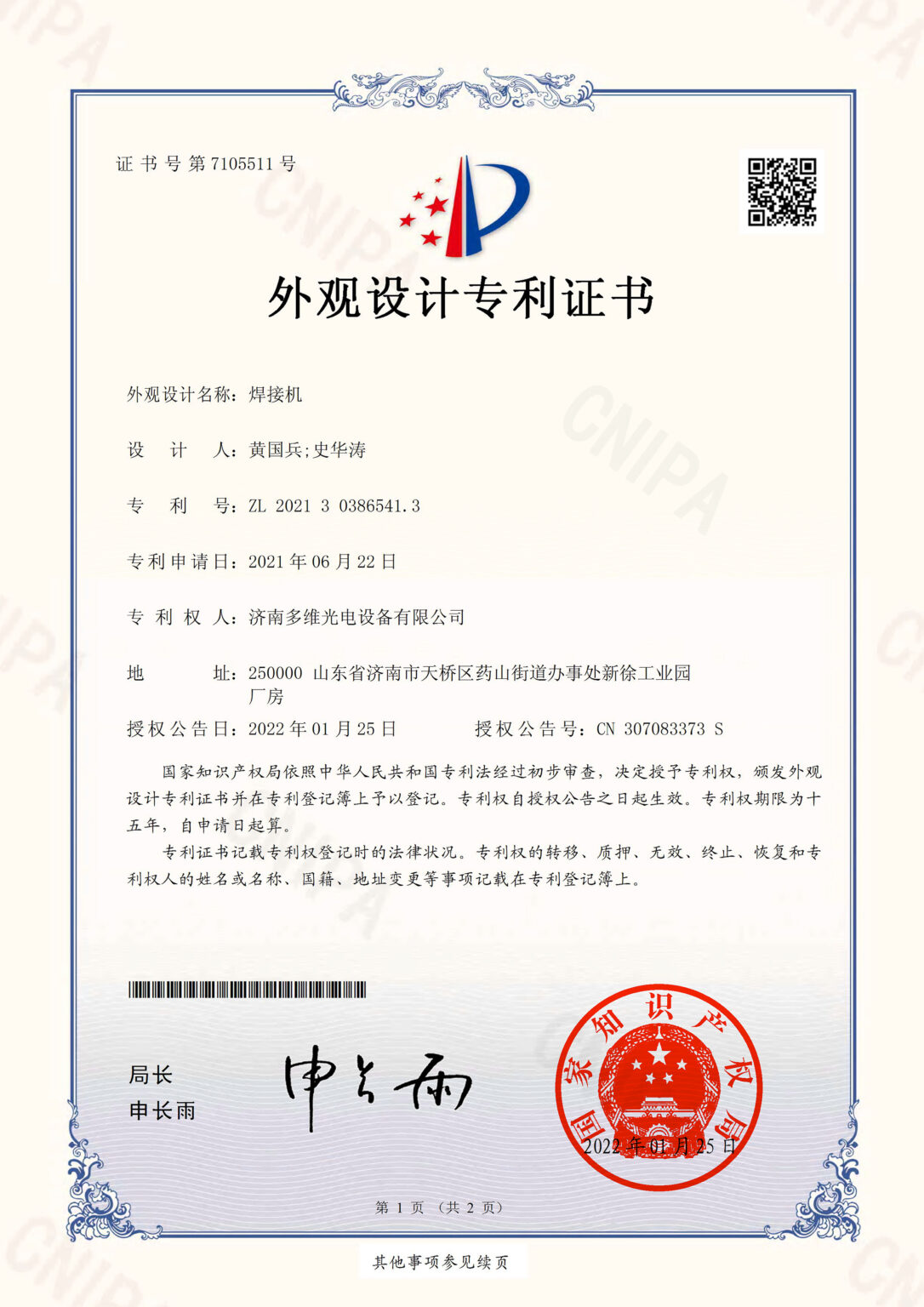

In 2014, obtained 16 patents for utility models and design patents.

In 2015, obtained global import and export rights for laser equipment and received the national-level high-tech enterprise certificate.

Building Core Technological Barriers

Dowell Laser has obtained two core patents for automatic line changing system for pipe laser cutting and tailless cutting system for pipe laser cutting machine. Through hardware structure innovation and software algorithm collaboration, it provides a high-end solution of "unmanned and zero waste" for pipe processing, accelerating the transformation of pipe processing towards efficiency, intelligence, and low cost.

Empowering Intelligent Manufacturing

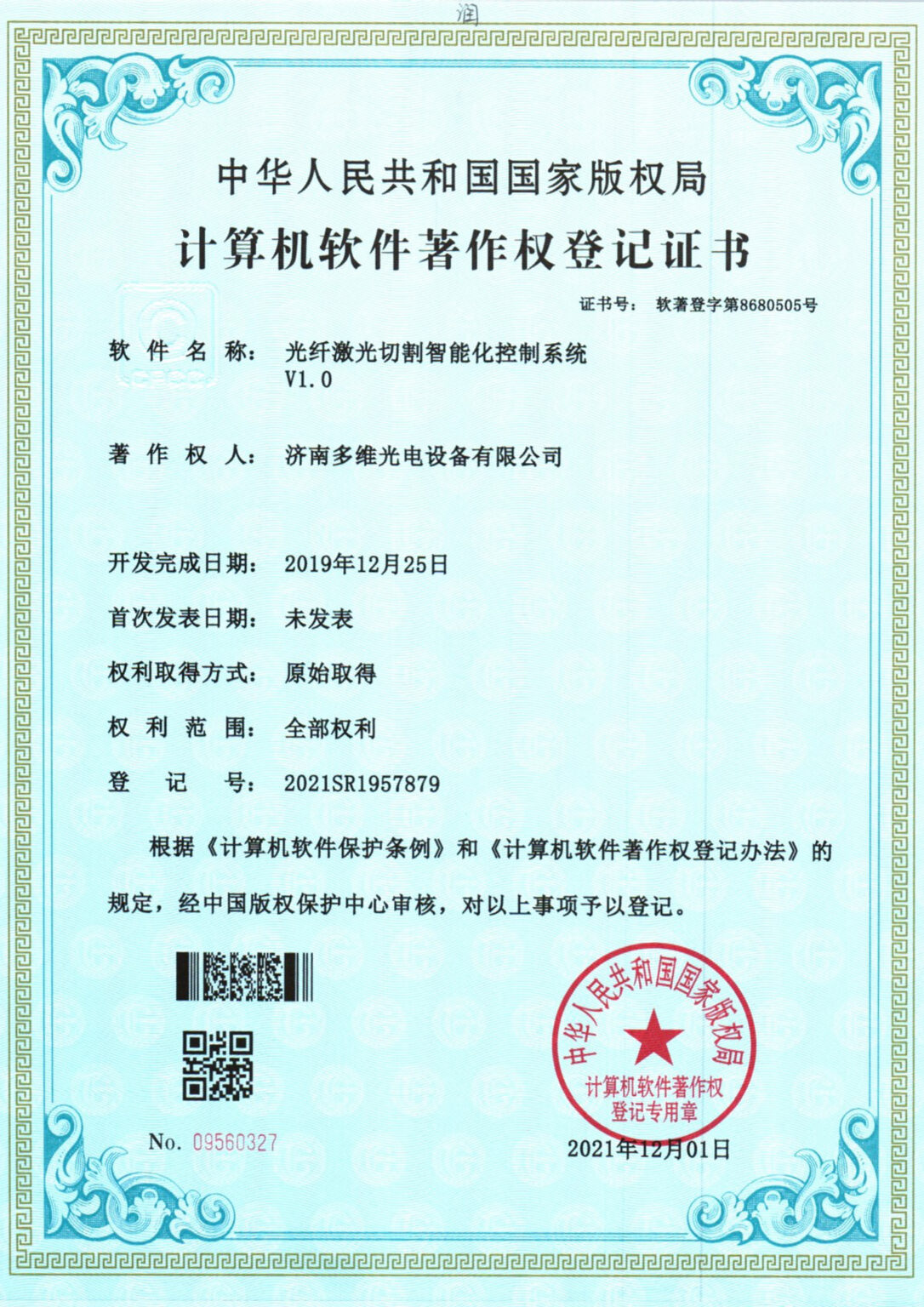

Leveraging its core technology R&D capabilities, Dowell Laser has obtained multiple software copyrights for laser cutting machines, covering key areas such as CNC systems, intelligent processes, and automation collaboration, thus building a complete and independently controllable software ecosystem.

Core Breakthrough of 3D 5Axis Technology

Dowell Laser independently developed 3D five-axis laser cutting technology, driving down the price of similar foreign products by more than 20%, overcoming the limitations of traditional processing methods for complex curved workpieces, and providing high-end localized solutions for industries such as automotive, aerospace, and construction machinery.

Sheet Metal Bending R&D

Flexible bending centers and multi-sided bending machines developed for the sheet metal processing industry have obtained production patents, further expanding the product range for complete one-stop metal forming production lines.

Laser Tube Cutting Product Upgrades

Addressing the market challenge of time-consuming and labor-intensive material handling in laser tube cutting machines, we have completed the production, research and development, and market launch of entirely new categories of laser tube cutting machines featuring fully automatic loading and unloading, bundle loading and unloading, and four-chuck systems.

Entering the Field of Structural Steel Processing

The professional production line for H-beam and I-beam laser processing centers was launched, completing the independent research and development and production of an integrated cutting machine for structural steel, plates, and pipes.

At the same time, a brand-new production line was established at the Yucheng production base.

Independent Innovation High-end & High-speed

Dowell Laser will unveil its independently developed high-speed laser cutting machine featuring a marble rigid base and linear motor direct-drive module. This machine will push the "speed, precision, and stability" of high-speed cutting to new industry heights, providing a "fast, accurate, stable, and cost-effective" high-end cutting solution for industries such as 3C electronics, new energy vehicles, and precision sheet metal, which demand both high processing efficiency and precision.

Hello,

We are a happy team. We develop Laser Cutting/Welding/Cleaning/ Cladding application for customers around the world.

Edward Yu

Focusing on international trade of laser equipment for 16+ years, responding to global customer needs 24 hours a day, fluent in English, supporting video factory inspections, real-time demonstrations, and remote meetings. To forge quality with professionalism and create value with integrity, your satisfaction is my eternal pursuit.

April Lv

As a laser industry foreign trade salesman with more than 10 years of experience, I focus on selling laser cutting/welding/cleaning machines to clients worldwide. I manage full sales cycles, offer technology consultations, and handle after-sales support. Detail-oriented and proactive, I stay updated on laser tech to serve clients better.

Lily Jiang

Strong language proficiency; Having experience in data processing and supply chain coordination, able to assist in order follow-up, logistics docking, and other related tasks; Can quickly understand customer needs, assist in product promotion and customer relationship maintenance.

Every honor is a microcosm of customer trust and industry recognition

Enterprise Honor & Certification

Global Agents & Distributors

Embark on a journey of global cooperation, and invite distributors and agents to embark on a new journey of wealth together

4785 Glen Streets

Item content. Click the edit button to change this text.

Mr. Beysembaev

Address: Republic of Kazakhstan, Oblast Abai, Semey Cisty.

Mr. Joe Mahugu Mwihungi

The Authorization Distributor: Kenya Somazar Ltd.

Egypt Branch Company

The Authorization Distributor: Egypt Souqmarket Company

Recognition across mountains and seas

Global Customer Trust and Witness Real Experiences and Evaluations from Global Customers

The inspection of the global market is the touchstone of products and services. Customers from Europe, America, Asia, Africa and other regions witnessed the cooperation scenarios in different industries, and each feedback carries affirmation of our quality and expectations for the future. We value every trust and are committed to passing on this recognition to more global partners.