As laser cleaning technology advances, Pulse Industries laser systems ( pulse industries laser paint remover) revolutionize traditional metal cleaning rules. Business owners are looking to become more competitive and reduce costs, so figuring out how much Pulse Industries lasers cost is key.

Whether you’re a professional looking to tweak your budget, or a newbie looking for the perfect laser technology, this detailed look at Pulse Industries laser costs will guide you in making an informed choice.

What is Pulse Industries Laser Systems

Pulse Industries Laser Systems (laser paint removal) deploy a laser source capable of delivering pulse energy. This results in a gentle light emission laser beam that cleans delicate surfaces without causing any damage.

Pulsed Laser Cleaners Working Principle

The idea of pulse laser cleaners is to get rid of things you don’t want on surfaces by using short bursts from a laser. Not only does this tech work well without causing damage, it’s also great at cleaning delicate materials. Industries that need things to be precise and clean have made the tool essential for day-to-day tasks. They’re nice because they’re environmentally friendly, non-contact, and super efficient. This makes them a really handy thing to have in your toolbox for all sorts of projects.

Types of Laser Cleaning System

The classification of laser cleaning machines (also called laser rust removers) can be mainly divided from their working principles, operating methods and application fields.

The classification of laser cleaning machines (also called laser rust removers) can be mainly divided from their working principles, operating methods and application fields.

According to the working principle

Laser cleaning machines are mainly divided into continuous laser cleaning machines, pulsed Gaussian laser cleaning machines and pulsed flat-top laser cleaning machines.

Continuous laser cleaning machines are mainly used for rust removal, oil removal, coating oxide layer removal, etc. on metal surfaces, and are highly cost-effective.

Operation method

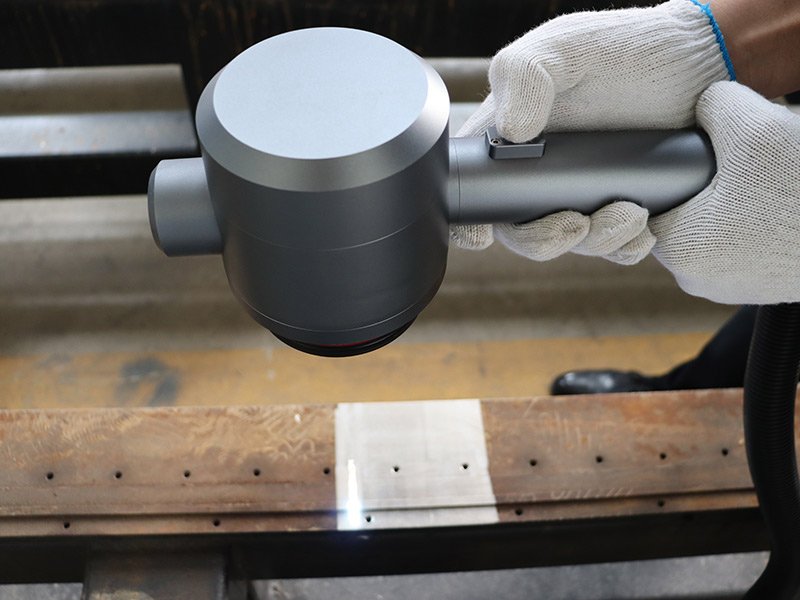

Laser cleaning machines can be divided into handheld, semi-automatic and fully automated laser cleaning equipment.

The handheld device can be widely used for non-standard and irregular paint removal, rust removal, contamination and scale removal, etc.

Semi-automatic laser cleaning equipment uses guide rails to install the scan head on the spindle driven by a servo motor to achieve semi-automatic operation.

Fully automated laser cleaning equipment further improves the automation of operations.

Laser cleaning machines are classified according to application areas

Mechanical parts laser cleaning machine mainly uses high-frequency and high-energy laser pulses to irradiate the surface of the workpiece to instantly evaporate or peel off oil stains, rust spots or coatings on the surface to achieve the purpose of cleaning.

This type of equipment usually has the characteristics of green cleaning, non-destructive cleaning, precision cleaning, and automatic cleaning. It can be widely used in many fields such as metal surface rust removal, surface paint removal treatment, rubber mold residue cleaning, and other fields.

Components of Pulse Laser Cleaners

- 1. Laser generator: The laser cleaning machine’s soul. It creates intense and fast beams.

- 2. Optical system: Like a director, it tells the laser’s beams Wo to go and how to get there.

- 3. Scanning head: The scanning head makes sure every inch is cleaned, acting as an invisible hand for the laser beam to follow.

- 4. Control system: This is like a conductor of an orchestra that brings everything together harmoniously – its purpose is to regulate the laser generator, optical system, scanning head, and more.

Handheld Laser Cleaning Solutions Advantages

Effizienz

These devices provide precise cleaning capabilities, ensuring that only the target surface is treated without causing damage to the surrounding area, making it environmentally friendly and pollution-free.

Portabilität

Their compact design makes them a versatile tool for a variety of cleaning applications, increasing productivity and reducing downtime.

Long term cost effectiveness

The initial investment may seem higher, but over time, the durability and efficiency of these machines reduce maintenance and operating costs, making them a worthwhile investment for businesses looking to streamline their cleaning processes.

Factors Influencing Pulse laser cleaning machine price

- Laser system technology and specifications. Higher power lasers with advanced features will naturally come at a higher price.

- A manufacturer’s brand reputation and reliability play a crucial role in pricing.

- The size and capacity of the laser machine also affects its cost. Larger machines with higher output capabilities typically cost more due to the increased materials and technology required.

- Customization options, such as specialized software or add-on accessories, may further increase the overall cost of Pulse Industries laser equipment.

Understanding these key factors can help you make informed decisions.

Comparative Analysis: Pulse Laser Cost vs. Competitors

| Besonderheit | Beschreibung | Impact on Cost |

|---|---|---|

| Pulse Laser Type | Excimer, Nd:YAG, Fiber | Excimer > Nd:YAG > Fiber |

| Известен своей надежностью и высокой скоростью резания, идеально подходит для промышленного использования. | Ultrashort, Nanosecond, Picosecond | Ultrashort > Nanosecond > Picosecond |

| Pulse Energy | Higher energy requires more robust components | Higher energy = Higher cost |

| Repetition Rate | Higher rates require faster pumping mechanisms | Higher rate = Higher cost |

| Average Power | Higher power requires more powerful components | Higher power = Higher cost |

| Strahlqualität | Excellent beam quality may come at a premium | Excellent quality = Higher cost |

| Customization | Coutume lasers are more expensive than standard models | Coutume = Higher cost |

Wie verwende ich Rostentfernungsgeräte mit Laserreinigung?

Using a laser cleaning machine for rust removal involves several steps:

Preparation:

- Safety First: Always wear laser safety glasses specific to the wavelength of your machine. Laser radiation can be harmful to your eyes. Additionally, consult the machine’s manual for any other recommended safety gear, like respirators or gloves.

- Workspace Setup: Ensure proper ventilation to remove dust and fumes generated during the cleaning process. You may also need to cover nearby surfaces to protect them from stray laser beams.

- Material Assessment: Identify the type of metal and the severity of the rust. Different metals may require adjustments in laser settings.

Cleaning Process:

- Maschineneinrichtung: Familiarize yourself with the machine’s controls and adjust settings based on the material and rust level. Refer to the manual for detailed instructions.

- Cleaning Technique: Hold the laser cleaning gun at a recommended distance from the surface. Typically, a sweeping motion is used to ensure even cleaning. Avoid staying in one spot for too long to prevent damaging the underlying metal.

- Monitoring and Adjustments: Continuously monitor the cleaning process and adjust settings as needed. Start with a low power setting and gradually increase it if necessary.

Finishing Up:

- Final Inspection: Once the rust is removed, visually inspect the cleaned area to ensure complete removal.

- Machine Maintenance: Follow the Hersteller‘s guidelines for cleaning the laser cleaning gun and performing any routine maintenance after use.

Additional Tips:

- It’s recommended to practice on a scrap piece of metal with similar rust levels before cleaning your actual project.

- Complex shapes or deep rust may require multiple cleaning passes.

- Laser cleaning is not suitable for all types of rust removal. Heavily pitted or uneven surfaces might require additional cleaning methods after laser treatment.

FAQ

Will laser cleaning metals surface damage ?

- Yes, it can, but the risk can be minimized with proper technique and settings.

- Potential damages include:

- Heat warping or melting

- Increased surface roughness

- Further embrittlement of brittle materials

- Ways to reduce the risk of damage:

- Use lower laser power settings and faster scan speeds

- Test on a similar scrap piece to determine optimal settings

- Maintain proper focus and distance

- Have an experienced operator perform the cleaning

- Alternative methods can be chosen for delicate surfaces:

- Media blasting

- Chemical cleaning

- Ultrasonic cleaning

Is it possible to produce a laser pulse that is shorter than its wavelength?

A laser pulse cannot be shorter than its wavelength.

- Wellenlänge: the physical distance between peaks of a light wave.

- Pulse duration: the time the light pulse exists.

It’s like a wave:

- A pulse cannot be shorter than the distance of one wave.

There are technicalities:

- Light can be emitted as wave packets.

- Wave packets have a minimum size related to the wavelength.

But fundamentally:

- A pulse cannot be shorter than its wavelength.