With the development of laser cutting technology, custom furniture is no longer a problem in the furniture manufacturing industry. Many metal furniture manufacturers have adopted this high-tech technology. Interior designers often use laser-cut metal panels to create unique and eye-catching feature walls.

This article will explore why laser cut furniture can completely change the industry and provide a lot of opportunities for companies.

How Laser Cutting Works

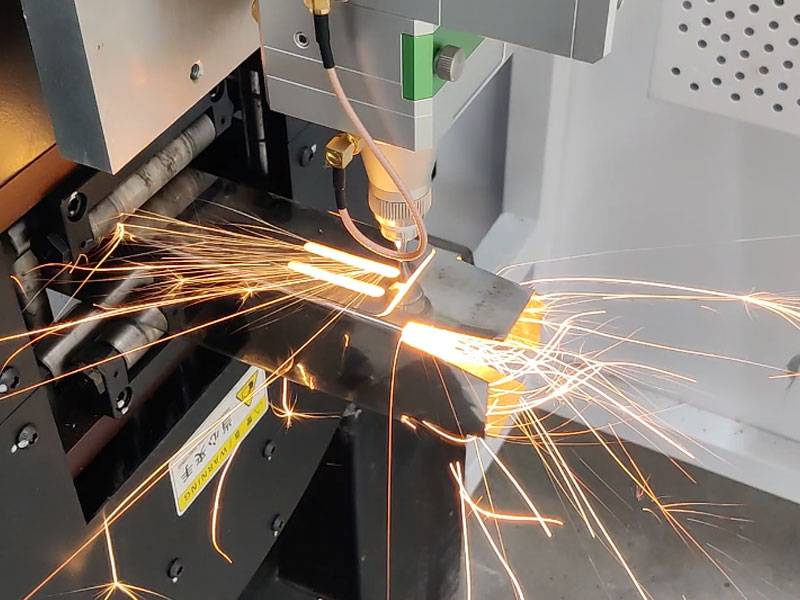

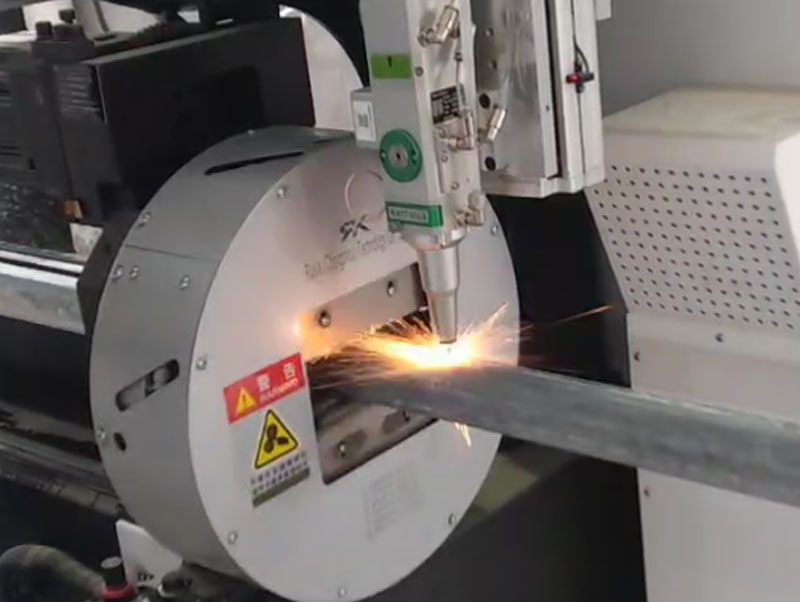

Laser cutting is a technology that uses a high-energy laser beam to cut materials. The laser is focused to a very small point through a focusing lens, generating high temperatures that melt or vaporize the material. Common types of lasers include CO2 lasers, fiber lasers, and solid-state lasers, each of which has its own specific application scenarios and advantages and disadvantages.

Common Materials for Laser Cutting

- Metalle: such as stainless steel, aluminum, copper, etc., suitable for making fine metal furniture.

- Holz: can be used to create complex wooden furniture designs.

- Acrylic: suitable for making transparent or colored decorative furniture.

Laser Equipment for Laser Cutting Furniture

- Leistung: 1000 W, 1500 W, 2000 W, 3000 W.

- Cutting materials: stainless steel, carbon steel, brass

Advantages of Laser Cutting Technology

- High precision and high efficiency

- Precise cutting: The laser cutting process can achieve extremely high cutting accuracy, whether it is a complex pattern or a small detail, it can be accurately presented.

- Schnelle Schnittgeschwindigkeit: Compared with traditional cutting methods, laser cutting is faster, which greatly improves production efficiency.

- No burrs: The laser cutting cut is smooth, no secondary processing is required, saving time and cost.

- Strong material adaptability

- Wide material compatibility: The laser cutting process is suitable for a variety of metal materials, such as stainless steel, aluminum alloy, carbon steel, etc., to meet different design requirements.

- Thickness adaptability: Whether it is a thin plate or a thick plate, the metal sheet cutting laser can do it, providing greater freedom for design.

- High design flexibility

- Any shape cutting: Laser cut furniture can cut patterns of any shape to meet personalized customization needs.

- Complex structure processing: It can easily handle complex structures and details to achieve exquisite furniture design.

- Environmental protection and safety

- No pollution: The laser cutting process is dust-free and pollution-free, meeting environmental protection requirements.

- Safe and reliable: High degree of automation, safe operation, and reduced human errors.

- Reduce costs

- Reduce material waste: High-precision cutting reduces material waste and reduces production costs.

- Shorten production cycle: High-efficiency production process shortens product delivery cycle.

- Improve product quality

- Exquisite appearance: The laser cutting cuts are smooth and neat, which improves the appearance quality of the furniture.

- Accurate size: High-precision cutting ensures the dimensional accuracy of the furniture and improves the overall quality of the product.

Application Scenarios for Laser Cut Furniture

Modern Furniture Design

Many modern metal furniture brands have begun to adopt fiber laser cutting technology. Some designers use laser cutting to create tables and chairs with geometric shapes. These works are not only functional but also have a high visual impact.

- Residential Furniture:

- Showcase examples of laser-cut furniture in living rooms, bedrooms, and dining areas, such as personalized coffee tables, dining tables, and bookshelves.

- Commercial Furniture:

- Introduce applications of laser-cut furniture in office settings, such as partitions, screens, and desks.

- Outdoor Furniture:

- Highlight the durability of laser-cut furniture for outdoor environments and showcase its use in gardens, parks, and recreational areas.

Customized Furniture Solutions

With the rise of personalized consumption trends, the demand for customized furniture is increasing. Using laser cutting technology, manufacturers can provide tailor-made solutions according to customer needs, such as making unique style bookshelves or display cabinets according to drawings provided by customers.

Advantages of Laser Cutting Furniture

Precision and Efficiency:

Explain how laser cutting achieves precise cuts with intricate patterns and fine details, significantly boosting production efficiency.

Compare laser cutting to traditional methods (e.g., waterjet cutting, plasma cutting), highlighting its superiority.

Materialvielfalt:

Discuss the wide range of metal materials (stainless steel, aluminum, carbon steel, etc.) that can be processed using laser cutting to meet diverse design requirements.

Environmental Friendliness and Safety:

Emphasize the low pollution and noise levels of laser cutting, aligning with modern environmental standards.

Design Freedom:

Explain how laser cutting breaks traditional processing limitations, enabling customized designs and fulfilling consumer demand for unique furniture.

Market Prospects for Laser-Cut Furniture

- Customization Trend:

- Analyze the growing consumer demand for personalized and customized furniture and how laser cutting technology fulfills this trend.

- Emerging Design Styles:

- Discuss how laser-cut furniture drives innovation in furniture design and sets new industry trends.

- Market Potential:

- Cite relevant data or market research reports to demonstrate the vast potential of the laser-cut furniture market.

How to Choose the Right Furniture Laser Cutting Machine

- Power Selection:

- Recommend suitable laser power based on material thickness and cutting complexity.

- Feature Selection:

- Introduce various auxiliary functions (e.g., automatic feeding, auto-focus) to help businesses choose the most suitable equipment.

- Brand Selection:

- Provide a brief overview of well-known laser cutting equipment brands and their features.

Future Trends in Metal Furniture Laser Cutting Machine

- Intelligenz:

- Predict the future development of laser cutting equipment towards intelligence and automation.

- New Material Applications:

- Explore the potential of laser cutting technology in processing new metal materials (e.g., titanium alloy, copper alloy).

- Integration with Other Technologies:

- Discuss the integration of laser cutting technology with 3D printing, artificial intelligence, and other technologies to create more innovative possibilities.

Abschluss

Laser cutting technology shows great potential in furniture manufacturing, especially in the field of metal furniture. Through flexible design, efficient production process and rapid response to market demand, enterprises can stand out from the competition. For metal furniture manufacturers, investing in laser cutting technology is not only an important way to improve product competitiveness, but also an inevitable choice for future development.

FAQ

What are the limitations of laser cutting furniture?

High-power laser cutting generates high temperatures, which may cause thermal deformation or discoloration of certain materials. Professionals are required to operate and maintain. Cutting produces smoke and dust, so you need to choose laser cutting equipment with enclosures.

How to control the cost of laser cutting furniture?

Choose the right laser cutting machine to balance performance and cost. Optimize the cutting process to reduce material waste. Batch production to reduce the cost of a single product.

What are the precautions for designing laser-cut furniture?

The characteristics of the material, avoid overly complex designs, and increase the difficulty of cutting. The structural stability of the furniture, ensures safe use. The style and aesthetics of the furniture, meet market demand.

How to achieve mass production of laser-cut furniture?

Use CAD/CAM software for design and programming. Establish standardized production processes. Introduce automated equipment to improve production efficiency.