When purchasing laser welding machines, many customers are not sure about the choice of single swing welding gun head or double swing welding gun head. Now this blog will explain it in detail, I hope it will be helpful to you.

Movement form

The single pendulum welding head can only do reciprocating swinging motion in one plane to form a linear weld.

The double pendulum welding head can do reciprocating swinging motion in two vertical planes at the same time, and can form various geometric welds, such as points, lines, circles, triangles, 8-shaped, etc.

Speed:

The double pendulum handheld laser welding head has a different speed than the single pendulum welding head. The biggest difference between the single pendulum and the double pendulum of laser handheld welding is their movement mode. The single pendulum is a unidirectional linear motion, that is, the welding head can only move in one direction, and the welding angle must be adjusted continuously during the welding process to meet the requirements of the welding surface. This mode is suitable for welding of small areas because it requires relatively high skills of welders.

The double pendulum handheld laser welding head is more flexible than the single pendulum. It can move in the horizontal and vertical directions, which makes it suitable for welding of large areas and work that requires welding smooth surfaces. The movement mode of the double pendulum is more complicated and requires some experienced welders to operate.

Flexibility and scope of application

The single pendulum handheld laser welding head has a single movement form and is suitable for occasions where the weld shape is simple.

The double pendulum welding head has flexible and changeable movement, which can meet the needs of complex weld shapes and has a wider range of applications.

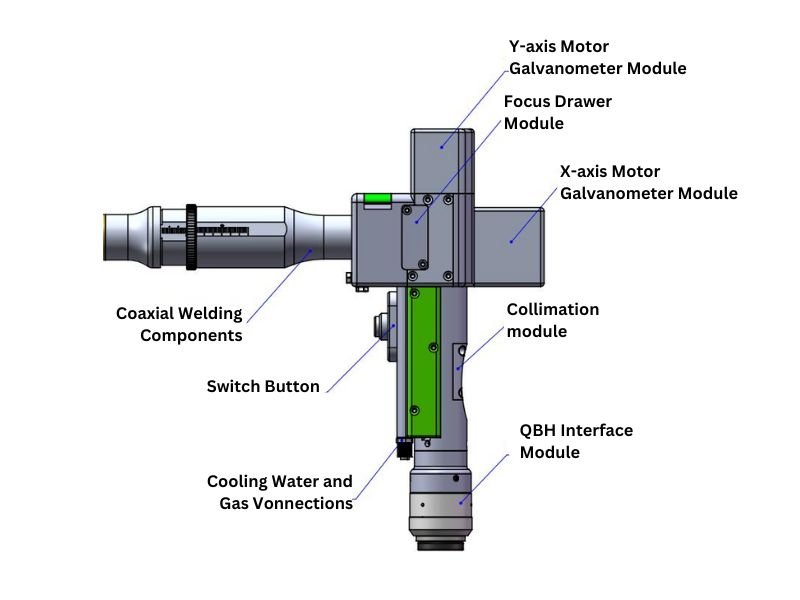

Structure and price

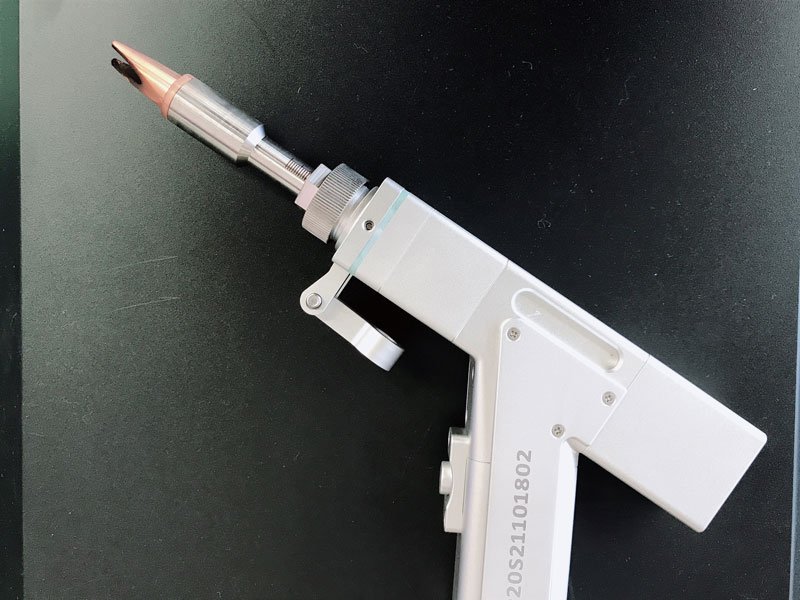

The single pendulum handheld laser welding gun has a relatively simple structure and a low price.

The double pendulum handheld laser welding gun has a complex structure and requires two independent motion systems, so the price is higher.

Application scenarios:

Single pendulum handheld laser welding head

Thin plate welding

The single-swing handheld welding gun has only one beam swing, and the weld shape is relatively simple, which is suitable for welding thin plate materials. Thin plates are easy to deform and require higher welding stability. The single-swing welding gun can meet this requirement.

Precision parts welding

For some precision parts, the welds require fineness and accurate position. The linear motion mode of the single-swing welding gun can better control the weld quality and ensure welding accuracy.

Small area welding

Due to the limited range of motion of the single-swing welding gun, it is more suitable for local welding of small areas. For large-area welding, the single-swing mode is less efficient.

Occasions with high requirements for welding stability

The single-swing welding gun has only one beam swing, and the motion trajectory is simple. It can achieve a relatively stable welding process and is suitable for application scenarios with high requirements for welding stability.

Single pendulum handheld laser welding head

Large area welding

The double-swing welding gun can move in both horizontal and vertical directions, which is suitable for large-area welding operations. It has high welding speed and processing efficiency, and has advantages in large-scale welding tasks such as automobile manufacturing and construction.

Need to weld smooth surfaces

The complex movement of the double-swing welding gun is suitable for work that requires welding smooth surfaces. It can achieve smoother weld transitions and meet high requirements for weld appearance quality.

Complex welding process

Due to the flexible and changeable movement of the double-swing welding gun, various geometric welds can be formed, which is suitable for occasions with more complex welding processes. Experienced welders can skillfully operate the double-swing welding gun to complete complex welding.

High requirements for welding efficiency

Compared with the single pendulum, the double-swing welding gun has a faster welding speed and higher processing efficiency, which is suitable for application scenarios with higher requirements for welding efficiency.

Conclusion

The double pendulum welding head has higher flexibility and applicability than the single pendulum welding head, but the structure is complex and the price is more expensive. When choosing, you need to weigh the pros and cons according to the specific welding requirements.

Related Article

- How To Choose Single Pendulum And Double Pendulum Handheld Laser Welding System

- How Much Is A Quick And Easy Laser Welding Tool Price?

- Features About China Shenzhen Qilin Laser Welding Head

- How To Reduce The Loss Of The Handheld Laser Welding Head

- What Are The Different Types Of Welding Machines Processes