Rust is very common in our lives, especially after the rusting of metal utensils, it is a headache to deal with, and the only cutting-edge technology that can remove stubborn rust is fiber laser cleaner rust removal, which can remove metal surface debris accurately and efficiently without pollution. This new technology is a new revolution in the field of rust removal.

This blog post delves into the fascinating world of fiber laser cleaner rust removal technology and its impact on the rust removal process. Let’s explore it together.

What is Fiber Laser Cleaner Technology

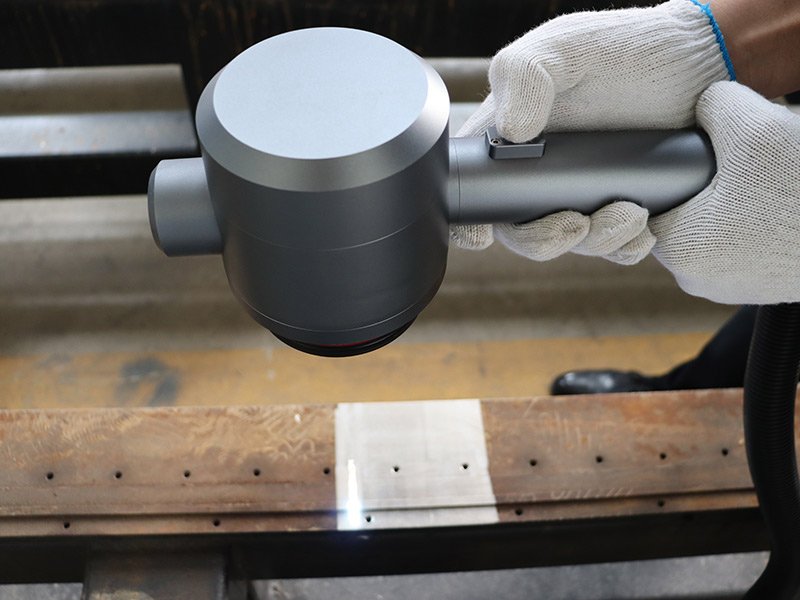

The fiber laser cleaning system is a new rust removal method that uses laser beams to eliminate corrosion on metal surfaces. Unlike traditional cleaning methods, fiber laser cleaning technology provides a more effective and precise solution. By directing a high-intensity laser beam into areas of rust, the technology vaporizes rust without damaging the underlying metal.

Function of handheld fiber laser cleaning machine

- Surface Preparation: Machines can prepare surfaces by removing dirt, grease, oil and other contaminants before painting, welding or coating processes.

- Rust and corrosion removal: It can effectively remove rust and corrosion on metal surfaces, and remove metal rust paint.

- , to restore it to its original state.

- Paint and coating removal: This machine can remove old paint, coatings and residues on the surface, and remove rust paint oxide without damaging the base material.

- Cleaning Delicate Surfaces: Precise control of the laser beam can gently clean delicate surfaces such as historical artifacts without causing damage.

- Eco-Friendly Process: Unlike traditional cleaning methods that use chemicals or abrasives, laser cleaning is a non-contact, eco-friendly process that produces no harmful fumes or waste.

- Increase productivity: Handheld fiber laser cleaners are portable, easy to use, and can get into hard-to-reach areas, making cleaning tasks more efficient and reducing downtime.

What is a pulsed laser cleaning system?

A pulsed laser cleaning system is a type of fiber laser cleaner technology that operates by emitting short pulses of high-energy laser light onto the surface being cleaned. These pulses rapidly heat up and vaporize the rust or contaminants on the surface, causing them to disintegrate into fine particles. The process is highly controlled and does not generate any harmful byproducts or residue.

Pulsed laser cleaning systems are particularly effective for removing tough rust or other stubborn contaminants from metal surfaces. They can be used on various materials such as steel, aluminum, copper, and more.

Type of fiber laser cleaner rust removal

Continuous laser cleaning machines and pulsed laser cleaning machines are two types of laser cleaning equipment used to remove contaminants, coatings, oxides, rust and other unwanted materials from surfaces.

| Feature | Continuous Laser Cleaning | Pulsed Laser Cleaning |

|---|---|---|

| Laser Beam | Continuous | Pulsed |

| Power | Lower | Higher |

| Cleaning Process | Gradual material ablation | Rapid material vaporization |

| Accuracy | High | Lower |

| Consistency | High | Lower |

| Speed | Slower | Faster |

| Best Applications | Precision cleaning,Cultural relics restoration | Removing tough coatings, thick contaminants |

Features of Handheld Laser Cleaning Machine

Fiber laser cleaners come with a range of features that contribute to their effectiveness and versatility. Some notable features include:

- Adjustable Power Settings: Handheld fiber laser cleaning machines allow users to adjust the power settings according to the specific cleaning requirements. This flexibility ensures optimal results for different types of rust or contaminants.

- Multiple Cleaning Modes: These laser cleaner metal machines often offer various cleaning modes, such as pulse mode or continuous wave mode, allowing users to adapt the cleaning process based on the surface and level of rust.

- Real-time Monitoring: Many portable fiber laser cleaner have built-in monitoring systems that provide real-time feedback on the cleaning process. This allows operators to make adjustments if necessary and ensures consistent and efficient results.

- Ease of Use: Laser cleaning rust is designed with user-friendliness in mind. They often feature intuitive interfaces and ergonomic designs, making them accessible even for operators with minimal training.

How Does fiber laser cleaner rust removal Work?

- Generate laser energy: Use a laser to generate a high-energy laser beam.

- Energy transmission: The laser beam is transported to the laser cleaning gun head through an optical fiber cable, and the gun head scans the substrate in a certain width through the scanning system.

- Surface interaction: When the laser beam irradiates the surface of the object, it interacts with oxides, rust or contaminants on the surface of the substrate. The high energy of the laser beam vaporizes, ablates or breaks down the rust, leaving the underlying material clean and intact.

- Cleaning process: The scanning system moves the laser beam across the surface in a controlled manner, ensuring that the entire area is evenly cleaned. Operators can adjust parameters such as laser power, scan speed and spot size to optimize the cleaning process for different types of materials and contaminants.

- Debris removal: When rust or contaminants are removed from a surface, they either evaporate into the air or turn into fine dust. Dust collection systems are often used to collect and process waste materials to ensure a clean working environment.

Fiber laser cleaner rust removers provide a fast, precise and environmentally friendly way to remove rust and other unwanted materials from a variety of surfaces including metal, stone and plastic.

How much fiber laser cleaner rust removal

The cost of cleaning metal rust can vary depending on various factors such as power output, features, and brand. The general price of laser cleaning machines on the market ranges from US$8,000 to US$100,000. Due to the different fiber laser selections of the machines and the different brand influence of the manufacturers, the prices also vary greatly.

Consult the supplier or manufacturer for accurate product information. Considering labor costs, post-maintenance and increased productivity, investing in fiber laser rust removal machine technology can prove to be very beneficial in the long run.

Fiber Laser Source Technology VS Traditional Methods

Fiber laser cleaner technology offers unmatched precision and efficiency compared to traditional rust removal methods. Unlike abrasive techniques like sandblasting, which can damage the underlying material, fiber laser cleaning precisely targets only the rusted area while leaving the rest of the surface intact.

Furthermore, fiber laser cleaning machines can reach intricate or hard-to-reach areas that may be challenging for traditional methods. This ensures a thorough cleaning process and eliminates any potential for residual rust or contaminants.

Fiber Laser Cleaner VS Traditional Methods

| Feature | Description | Benefit |

|---|---|---|

| Precision & Control | Precisely removes contaminants without damaging the underlying surface. | Reduces risk of over-cleaning and damage compared to traditional methods. |

| Environmentally Friendly | Non-contact, non-abrasive cleaning eliminates the need for harsh chemicals or abrasives. | Safer for the environment compared to traditional methods that use harmful materials. |

| Efficiency | Quickly and effectively removes contaminants or coatings. | Saves time and effort compared to traditional methods. |

| Safety | Reduces risk of operator injury from hazardous chemicals, dust, or noise. | Creates a safer work environment. |

| Cost-Effectiveness | May have higher upfront cost, but lower maintenance and operating costs in the long run. Increased efficiency saves labor and material costs. | Potentially more cost-effective than traditional methods over time. |

Fiber laser cleaning has many advantages over traditional cleaning methods in terms of accuracy, controllability, environmental protection, efficiency, safety, and cost-effectiveness. It is a modern and advanced cleaning technology that is increasingly adopted by various industries because of its excellent cleaning capabilities.

Applications for Rust Dust Removal

Fiber laser cleaner technology finds applications in various industries where rust removal is essential. Some common areas where this technology is utilized include:

- Automotive Industry: Removing rust from car bodies, engine components, or other metal parts.

- Aerospace Industry: Cleaning rust from aircraft surfaces, engine parts, or other critical components.

- Metal Fabrication: Preparing metal surfaces for welding or painting by removing rust and contaminants.

- Maintenance and Repair: Restoring old machinery or equipment by eliminating rust and extending their lifespan.

Enhancing Safety Standards: Minimizing Risks in Industrial Cleaning Processes

Fiber laser cleaner technology offers significant safety advantages over traditional methods. By eliminating abrasive materials and chemicals, it reduces the risk of accidents, such as inhalation of harmful substances or injuries caused by abrasive particles.

Furthermore, the non-contact nature of fiber laser cleaning minimizes the chances of surface damage or distortion. This is particularly important in industries where precision and quality are paramount.

Future Innovations and Developments in Laser Cleaning Technology

The field of laser cleaning technology continues to evolve, with ongoing research and development driving further advancements. Some areas of focus for future innovations include:

- Increased Power and Efficiency: Researchers are working on enhancing the power output and efficiency of fiber laser cleaning machines to improve their performance.

- Expanded Material Compatibility: Efforts are being made to expand the range of materials that can be effectively cleaned using fiber laser technology.

- Miniaturization: There is a growing interest in developing smaller, portable fiber laser cleaning devices for applications where mobility is crucial.

How Fiber Laser Cleaner Technology is Revolutionizing Rust Removal

Fiber laser cleaner technology has revolutionized rust removal processes by offering a faster, more precise, and environmentally-friendly solution. Its ability to remove rust without damaging the underlying material makes it highly versatile across various industries.

The adoption of this technology not only improves efficiency but also enhances workplace safety and reduces environmental impact. As industries continue to prioritize sustainability and seek innovative solutions, fiber laser cleaner technology is poised to play a significant role in shaping the future of rust removal processes.

Technical Parameters of Fiber Laser Cleaning Machine

The technical parameters of a fiber laser cleaning machine may vary depending on the specific model and manufacturer. Some common parameters to consider include:

- Power Output: The power output of a fiber laser cleaning machine determines its cleaning capability. Higher power outputs generally allow for more efficient and faster rust removal.

- Pulse Frequency: The pulse frequency refers to the number of laser pulses emitted per second. Higher frequencies can result in faster cleaning speeds.

- Beam Diameter: The beam diameter affects the spot size and precision of the cleaning process. Smaller beam diameters offer higher precision but may require more time for larger surfaces.

- Cleaning Range: The cleaning range indicates the distance between the machine and the surface being cleaned. It is essential to choose a machine with an appropriate cleaning range for the intended application.

It is advisable to consult with manufacturers or suppliers to determine the most suitable technical parameters based on specific rust removal requirements.

In conclusion, fiber laser cleaner technology has emerged as a game-changer in rust removal processes. Its precision, efficiency, and eco-friendly nature make it an attractive alternative to traditional methods. As industries continue to embrace sustainable solutions, fiber laser cleaner technology is set to revolutionize rust removal across various sectors, paving the way for a cleaner and more efficient future.

FAQ

What is the best rust remover for metal?

Fiber Laser Cleaner Technology stands out as one of the best rust removers for metal surfaces. Its precision and efficiency make it an ideal choice for industries where maintaining clean and corrosion-free surfaces is crucial.