In today’s fast-paced manufacturing world, efficiency and precision are key. One technology that embodies these qualities is tube laser cutting. If you’re new to this concept, don’t worry. This blog post will introduce you to the basics of tube laser cutting, its benefits, and why it might be the perfect solution for your business needs.

What is Tube Laser Cutting?

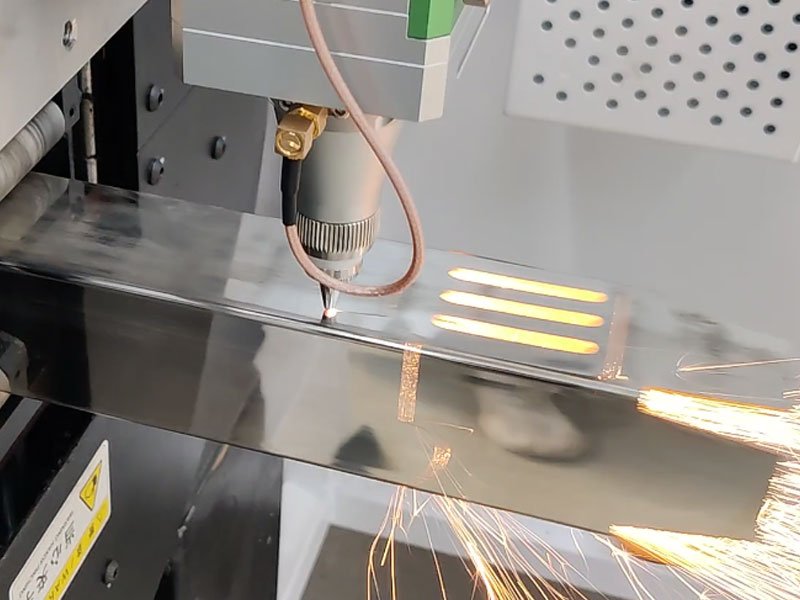

Tube laser cutting is a method of using a laser to cut and shape tubes of various materials, such as steel, stainless steel, aluminum, brass, and more. This technology allows for precise cuts and intricate designs, making it a versatile tool for many industries.

How Does Tube Laser Cutting Work?

- Laser Source: A fiber laser source generates a high-powered laser beam.

- Guiding System: The laser beam is directed through a series of mirrors and lenses to the cutting head.

- Cutting Head: The cutting head focuses the laser beam onto the material.

- Movement System: The material is held in place by chucks that rotate and move to ensure the laser cuts precisely where needed.

- Control System: A CNC (Computer Numerical Control) system directs the laser and material movement, following a pre-programmed design.

Laser Tube Cutting Material

Laser tube cutting technology is highly versatile and can work with a wide range of materials, making it suitable for various industrial applications.

- Carbon Steel

- Properties: Strong, durable, and relatively inexpensive.

- Applications: Widely used in construction, automotive parts, and machinery manufacturing.

- Stainless Steel

- Properties: Corrosion-resistant, strong, and aesthetically pleasing.

- Applications: Ideal for medical instruments, kitchen appliances, and decorative elements.

- Aluminum

- Properties: Lightweight, corrosion-resistant, and highly conductive.

- Applications: Commonly used in aerospace components, automotive parts, and lightweight structures.

- Brass

- Properties: Highly malleable, corrosion-resistant, and has a low melting point.

- Applications: Frequently used in musical instruments, plumbing fixtures, and decorative hardware.

- Copper

- Properties: Excellent electrical and thermal conductivity.

- Applications: Used in electrical components, heat exchangers, and plumbing systems.

- Titanium

- Properties: High strength-to-weight ratio, corrosion-resistant, and biocompatible.

- Applications: Suitable for aerospace parts, medical implants, and high-performance automotive components.

Laser tube cutting machines can handle various shapes, including round, square, and rectangular tubes, and are capable of producing complex geometries and precise cuts. This flexibility in material compatibility makes laser tube cutting a preferred method in many industries.

Tube Pro Laser Cutting Software

Effective laser tube cutting not only relies on the hardware but also heavily on the software that controls the cutting process. Tube Pro is one such advanced software solution designed to optimize and streamline laser tube cutting operations.

User-Friendly Interface

- Feature: Intuitive and easy-to-navigate interface.

- Benefit: Reduces the learning curve, allowing operators to quickly become proficient in using the software.

Advanced Nesting Algorithms

- Feature: Optimizes the arrangement of parts to minimize material waste.

- Benefit: Increases material utilization and reduces production costs.

Comprehensive Design Tools

- Feature: Supports a wide range of design file formats and provides tools for creating complex geometries.

- Benefit: Enhances design flexibility and ensures compatibility with various CAD programs.

Real-Time Monitoring and Diagnostics

- Feature: Provides real-time feedback on the cutting process and machine status.

- Benefit: Helps in identifying and addressing issues promptly, ensuring smooth operation and reducing downtime.

Automated Features

- Feature: Includes automatic loading and unloading, automatic centering, and focusing functions.

- Benefit: Streamlines the production process, increases efficiency, and reduces the need for manual intervention.

Customizable Settings

- Feature: Allows for customization of cutting parameters based on material type and thickness.

- Benefit: Ensures optimal cutting quality and efficiency for different materials and applications.

Support and Updates

- Feature: Regular software updates and customer support.

- Benefit: Keeps the software up-to-date with the latest features and improvements, providing ongoing support to users.

By integrating Tube Pro laser cutting software with your laser tube cutting machine, you can significantly enhance the precision, efficiency, and overall productivity of your cutting operations. This powerful combination ensures that you can meet the diverse and demanding requirements of modern manufacturing.

Benefits of Tube Laser Cutting

- Precision: Tube laser cutting offers exceptional precision, with cutting accuracy up to ±0.03mm. This allows for the creation of complex shapes and intricate designs that would be difficult or impossible to achieve with traditional cutting methods.

- Efficiency: The high cutting speed (up to 100 meters per minute) and automation capabilities significantly reduce production time, making it ideal for high-volume manufacturing.

- Versatility: Tube laser cutting machines can handle a wide range of materials and tube shapes, including round, square, and rectangular tubes. This versatility makes it suitable for various industries such as automotive, aerospace, construction, and furniture manufacturing.

- Cost-Effectiveness: By reducing the need for additional processing steps and minimizing material waste, tube laser cutting can lower overall production costs. The precision also reduces the likelihood of errors, saving time and resources.

- Automation: Many tube laser cutting machines come with features like automatic loading and unloading systems, real-time monitoring, and diagnostic systems, which streamline the production process and reduce the need for manual intervention.

Applications of Tube Laser Cutting

- Automotive Industry: Creating components such as exhaust systems, chassis, and intricate parts that require high precision.

- Furniture Manufacturing: Producing metal furniture frames and decorative elements with intricate designs.

- Aerospace: Cutting high-strength materials for aircraft components, ensuring they meet stringent industry standards.

- Construction: Cutting structural components like beams and columns for buildings and bridges.

- Medical Devices: Creating precise and detailed components for medical instruments and devices.

Why Choose Tube Laser Cutting?

If your business involves working with tubes and pipes, investing in a tube laser cutting machine can offer numerous advantages. The precision, efficiency, and versatility of this technology can enhance your production capabilities, improve product quality, and reduce costs.

Conclusion

Tube laser cutting is a powerful technology that has transformed the manufacturing landscape. Its ability to provide precise, efficient, and versatile cutting solutions makes it an invaluable tool for a wide range of industries. Whether you’re in the automotive, aerospace, construction, or furniture manufacturing industry, understanding and utilizing tube laser cutting can give your business a competitive edge.

If you’re interested in learning more about tube laser cutting or exploring our range of cutting-edge machines, feel free to contact us. We’re here to help you find the perfect solution for your manufacturing needs.