For many users who purchase metal tube laser cutting equipment, choosing the right tube laser cutting machine is important, but choosing the right tube laser cutting machine is more important.

This blog post will focus on the two common forms of laser cutting pipe equipment : Stereoscopic Cutting Vs Vertical Cutting. I hope it will be helpful to you.

Before Purchasing a Tube Laser Cutting Machine, You Need to Know

1.Understand your needs

For example, factors such as the shape and size of the tube, the requirements for cutting graphics, and after-sales service. Industrial processing equipment is not as ubiquitous as car repair.

2.The cost of tube laser cutting machine

Purchase the ideal laser tube cutting equipment within the cost range that you can afford.

Stereoscopic Cutting Vs Vertical Cutting

Among the cutting methods of laser tube cutting machines, there are currently three common forms of laser cutting machines on the market. Stereoscopic cutting and vertical cutting are the most common methods used in laser cutting machines. The biggest difference is mainly in the movement mode and applicable scenarios of the fiber cutting head.

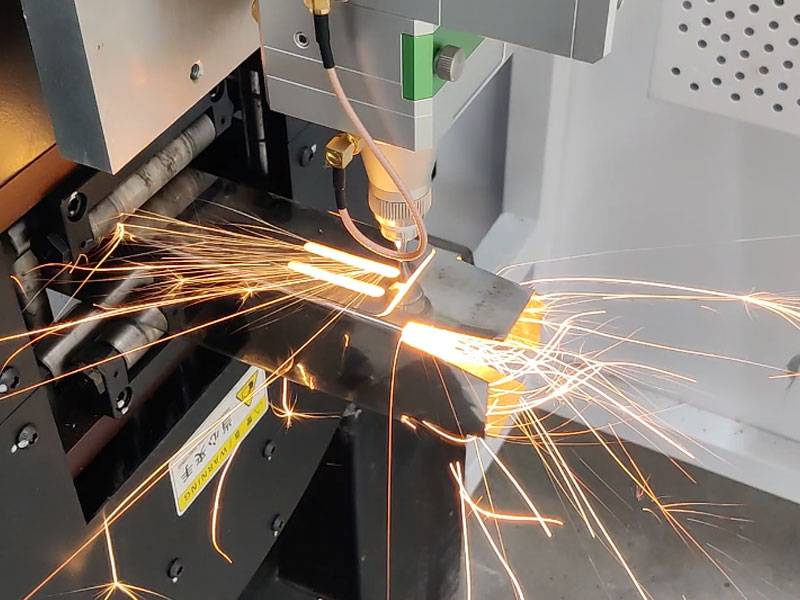

1.Vertical cutting

The laser cutting head can only move up and down, which is mainly suitable for cutting round tubes, mainly to achieve cutting power.

Advantages: high efficiency and high cost performance

Disadvantages: single processing method

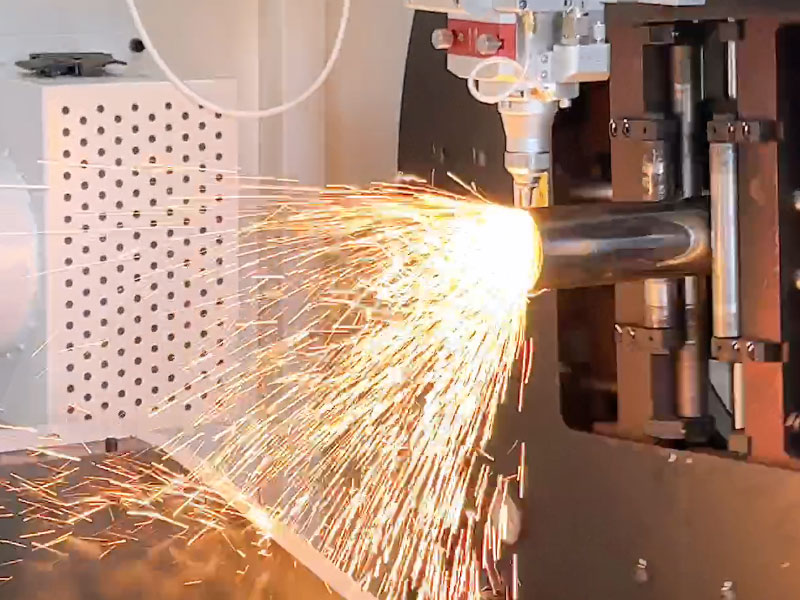

2.Stereoscopic cutting

On the basis of vertical cutting, horizontal and vertical cutting are added to suit the vertical cutting of square tubes, special-shaped tubes, round tubes, etc. on the surface of metal tubes.

Advantages: It can meet a variety of processing needs, and realize cutting and punching on metal tubes.

Disadvantages: Corner splicing requires special treatment, and three-dimensional drawing personnel are required to cooperate.

3.Three-dimensional cutting

On the basis of three-dimensional laser cutting, a laser cutting head with tilting function is added. “Five-dimensional laser tube cutting” is the bevel function of the laser tube cutting machine

Advantages: It can realize the bevel and groove cutting functions

Disadvantages: The current market price is expensive and immature compared to ordinary laser cutting heads

Chuck method:

- Single chuck: economical and affordable, but the disadvantage is that the application field is single, mainly used for vertical cutting

- Dual chuck: It can realize automatic feeding and non-automatic feeding functions. It is assumed that metal pipes will have excess tailings in the later stage, causing material loss, and manual cutting and processing are required

- Multiple chucks: It can achieve 0 tailing cutting, but the disadvantage is that there are many brands of fiber lasers, and the market prices are very different.

Comparative Analysis of Stereo Cutting and Vertical Cutting

| Comparison Factor | Stereoscopic Cutting | Vertical Cutting |

|---|---|---|

| Cutting Precision | Excels in cutting complex 3D shapes and surfaces with high precision, but may be influenced by machine calibration. | Offers higher precision in 2D cutting, with stable operation, suitable for simple geometric shapes. |

| Material Utilization | High material utilization, ideal for complex shapes and polyhedral cutting, minimizing waste. | Lower material utilization, may produce more waste when cutting complex shapes. |

| Processing Speed | Slower processing speed due to the complexity of 3D paths, suitable for small batches and high-precision cuts. | Faster processing speed, ideal for mass production and 2D shape cutting, with simpler paths. |

| Operational Complexity | High operational complexity, requiring specialized skills and involves complex 3D spatial control. | Relatively simple operation, suitable for most operators, with standardized processes. |

| Equipment Cost | Higher equipment cost due to complex 3D control systems, with higher maintenance expenses. | Lower equipment cost, with simple design and lower maintenance costs. |

When to choose 3D cutting or vertical cutting

Automotive industry: In the manufacture of automobile exhaust systems, pipes require complex bending and special-shaped cutting, and 3D cutting is more suitable for such high-complexity needs. For frames or other straight pipes, vertical cutting can complete the task quickly and efficiently.

Construction industry: Building support structures or decorative pipes require precision cutting at multiple angles, and 3D cutting is a better choice. When standard steel pipe cutting is used for building support, vertical cutting has an advantage because of its fast speed.

Furniture manufacturing: Furniture frames and brackets usually require standard-sized pipe cutting, and vertical cutting can complete these tasks efficiently. For some unique design elements, 3D cutting may be required to achieve complex shapes.

How to choose the right cutting technology for different pipe processing

3D cutting:

Suitable for cutting pipes with complex shapes and multiple angles, such as cutting exhaust pipes in automobile manufacturing or cutting special-shaped support structures in construction. Three-dimensional cutting can achieve multi-axis linkage, making the cutting curve more precise and complex, meeting the needs of high-end manufacturing.

Three-dimensional cutting is also more advantageous in situations where materials need to be saved and utilization rates need to be improved, because it can maximize the use of each part of the pipe and reduce waste.

Vertical cutting:

More suitable for standard pipe cutting that requires high speed and high precision, such as cutting table and chair brackets in furniture manufacturing or cutting pipe fittings in pipeline engineering. The cutting path of vertical cutting is simple and stable, and can quickly complete mass production.

For medium and low complexity cutting tasks, vertical cutting can provide an economical and efficient solution for most conventional industrial applications.

Future development of laser tube cutting technology

Automation and intelligence: With the development of Industry 4.0, laser tube cutting machines will increasingly integrate automation and intelligent technologies. Automation devices will be able to automatically adjust the position and cutting path of the laser, reduce manual intervention, and improve production efficiency.

Multifunctionality: Future laser cutting machines will not only be limited to cutting functions, but may also integrate other processing technologies such as punching, welding, and marking, enabling the equipment to complete multiple tasks in one stop.

Improvement space for stereoscopic cutting and vertical cutting technology

Stereoscopic cutting:

- Precision improvement: By improving the control accuracy of the laser and the motion system of the equipment, the future stereoscopic cutting technology will be able to maintain high-precision cutting on more complex geometric shapes.

- Speed optimization: Through faster motion control and laser scanning speed, the processing speed of stereoscopic cutting is expected to be further improved, making it more widely used in mass production.

Vertical cutting:

- Material adaptability: With the development of new materials, vertical cutting technology will continue to be optimized to adapt to different types of metal and alloy pipes and improve its cutting quality.

- Energy efficiency improvement: By using more efficient laser sources and optimized cutting paths, vertical cutting will become more energy-saving and environmentally friendly, reducing energy consumption.

Conclusion

Stereoscopic cutting is suitable for complex shapes and multi angle cutting, and is suitable for occasions requiring high precision and high material utilization. Vertical cutting is good at fast cutting of simple shapes, and is suitable for mass production and conventional processing needs.