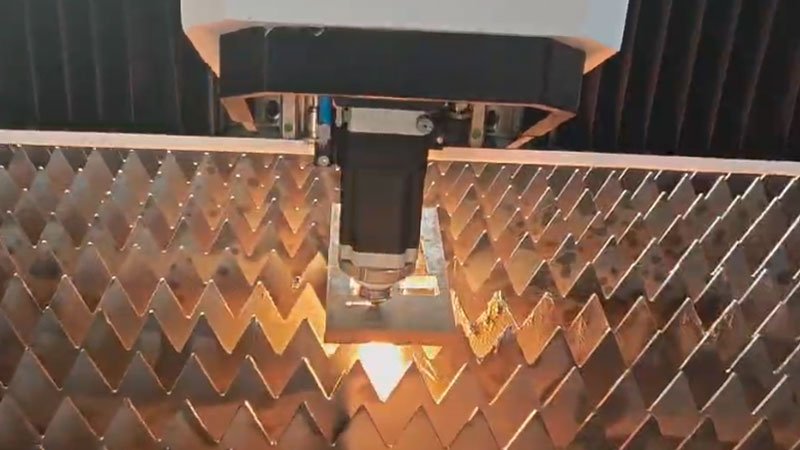

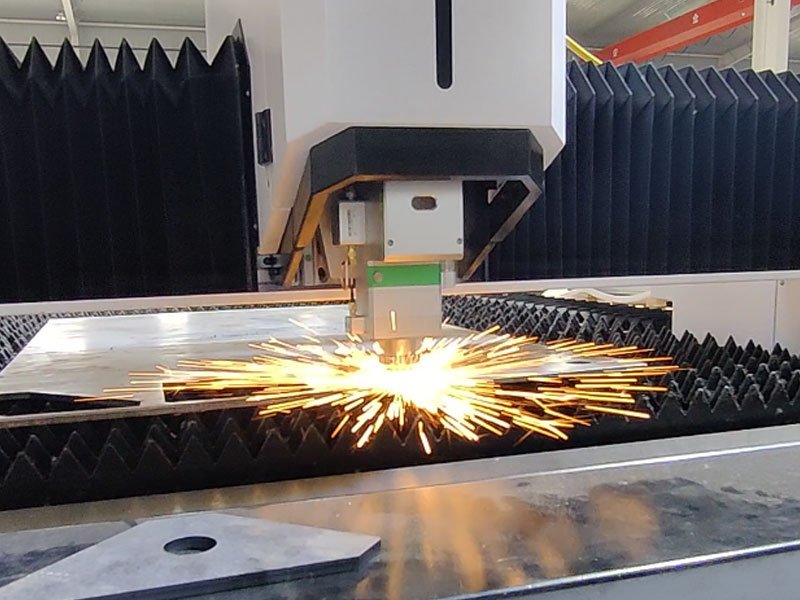

As a manufacturer of fiber laser cutting machines, we understand that the quality of laser cutting is paramount to our customers’ satisfaction and success. Whether you are in the automotive, aerospace, or metal fabrication industry, achieving precise, clean cuts is critical to maintaining high standards in your production process.

In this blog post, we will delve into the factors that influence laser cutting quality and how our fiber laser cutting machines are designed to meet and exceed these demands.

What is Laser Cutting Quality

Laser cutting quality is determined by several key factors that collectively ensure the accuracy, smoothness, and consistency of the cuts. These factors include:

- Precision: The ability to produce cuts with exact dimensions as specified.

- Edge Quality: The smoothness and finish of the cut edges, which should be free of burrs and roughness.

- Consistency: The ability to produce uniform cuts across multiple parts.

- Minimal Heat-Affected Zone (HAZ): Reducing the area around the cut that is affected by heat to preserve the material’s properties.

What Are The Factors Affecting Fiber Laser Cutting Quality?

- Laser Power and Stability

- Power Levels: Sufficient laser power is crucial for cutting through various material thicknesses. Our fiber laser cutting machines are equipped with high-power lasers that can handle a wide range of materials, from thin sheets to thick plates.

- Power Stability: Consistent power output ensures uniform cuts and reduces the likelihood of defects. Our machines are designed to maintain stable power levels throughout the cutting process.

- Beam Quality

- Beam Focus: A well-focused laser beam is essential for achieving precise cuts. Our fiber laser cutting machines utilize advanced optics to maintain a sharp focus, resulting in clean and accurate cuts.

- Beam Mode: The quality of the laser beam mode affects the smoothness of the cuts. Our machines are engineered to produce high-quality beam modes that ensure superior edge quality.

- Cutting Speed and Feed Rate

- Optimal Speed: The cutting speed must be optimized for the material type and thickness to achieve the best quality. Our machines offer adjustable cutting speeds that can be fine-tuned for different materials.

- Feed Rate: The rate at which the material is fed into the laser beam also impacts cut quality. We provide precise control over feed rates to ensure consistent and clean cuts.

- Assist Gas and Nozzle Design

- Assist Gas: The type of assist gas (such as oxygen, nitrogen, or air) and its pressure play a crucial role in the cutting process. Our fiber laser cutting machines are equipped with systems that allow users to choose the appropriate gas and pressure settings for their specific needs.

- Nozzle Design: The design and condition of the nozzle affect the quality of the gas flow and, consequently, the cut. Our machines use high-quality nozzles designed to provide optimal gas flow and reduce contamination.

- Material Properties

- Material Type: Different materials react differently to laser cutting. Our machines are versatile and capable of cutting a wide range of metals and non-metals with precision.

- Material Thickness: The thickness of the material affects the required laser power and cutting speed. Our machines are designed to handle various thicknesses, providing clean cuts regardless of the material’s dimensions.

Fiber Laser Cutting Machines Meet Quality Demands

- Advanced Laser Technology Our machines incorporate the latest fiber laser technology, ensuring high power, stability, and beam quality. This technology allows for precise and efficient cutting across a wide range of materials and thicknesses.

- Precision Optics and Control Systems We use advanced optics and control systems to maintain accurate beam focus and optimize cutting parameters. This results in superior edge quality and minimal heat-affected zones.

- Customizable Settings Our fiber laser cutting machines offer customizable settings for cutting speed, feed rate, assist gas type, and pressure. This flexibility allows users to fine-tune the machine for optimal performance on different materials.

- Robust Build and Durability Built with high-quality materials and components, our machines are designed for durability and reliability. This ensures consistent performance and long-term use with minimal maintenance.

- Comprehensive Support and Training We provide comprehensive support and training to help users maximize the capabilities of our fiber laser cutting machines. From initial setup to ongoing maintenance, our team is dedicated to ensuring you achieve the highest cutting quality possible.

Conclusion

Achieving top-notch laser cutting quality is essential for any industry relying on precise and clean cuts. Our fiber laser cutting machines are engineered to meet the highest standards of precision, edge quality, and consistency. By addressing key factors such as laser power, beam quality, cutting speed, assist gas, and material properties, we ensure that our machines deliver exceptional performance for all your cutting needs. Invest in our fiber laser cutting machines and experience the difference in quality and efficiency for yourself.