chinese fiber handheld laser welder manufacturers

what is a laser welder

Laser welding machine is a device designed for precision welding using laser technology. It uses a laser beam to heat and melt materials so they can join together seamlessly.

The weight of the handheld laser welding machine is 39kg. Compared with the water-cooled handheld welding machine, it has greater advantages in weight and volume.

There is basically no deformation during welding, which greatly improves work efficiency compared with traditional argon arc welding.

best handheld laser welder for sale

Do you want to purchase a handheld laser welder? There are many laser welding machine for sale brand manufacturers on the market. You can find a suitable handheld laser welder among so many brands, and the prices and costs vary. Our company has 1000w/1500w/2000w/3000w equipment with different powers for you to choose from.

lightweld 1500 for sale

handheld laser welder for sale

3 in 1 laser welding machine

Laser welding machine benefits

Laser Source: The machine is equipped with a laser source, which can be of various types such as fiber lasers, CO2 lasers, or solid-state lasers. The choice of laser source depends on the specific application and material.

Focused Beam: The laser beam is focused on the welding area, generating intense heat. This focused energy creates a localized molten pool, allowing for precise and controlled welding.

Material Compatibility: Laser welding is versatile and can be used for welding a wide range of materials, including metals, plastics, and even dissimilar materials.

Precision and Speed: One of the main advantages of laser welding is its ability to provide high precision and speed. It is commonly used in applications where fine details and accuracy are crucial. where fine details and accuracy are cruc

- Contactless Process: Laser welding is a non-contact process, meaning that the laser beam does not physically touch the materials. This is beneficial for delicate or sensitive materials.

- Automation Compatibility: Laser welding machines can be integrated into automated systems, making them suitable for high-volume production processes.

Applications: Laser welding is utilized in various industries, including automotive, aerospace, electronics, medical, and jewelry. It is chosen for applications where a clean and precise weld is essential.

Advantages: Some advantages of laser welding include minimal thermal distortion, small heat-affected zone, and the ability to weld complex geometries.

Welding Types: There are different types of laser welding, including conduction welding and keyhole welding, each suitable for specific applications.

laser welder gun

The welding head is the part that focuses the laser beam to the welding part, and is mainly composed of focusing lens, protective mirror, reflector, etc.

handheld laser welding system

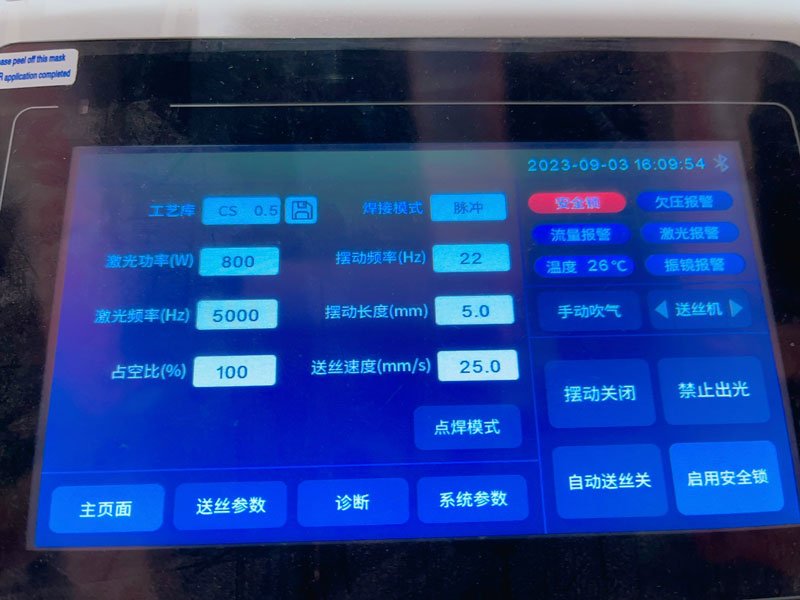

It is mainly composed of computer, control card, motion, etc. The control can control the movement and work of the laser, beam transmission, welding head, workbench and other parts to achieve automated control of the welding process.

Fiber Optic Laser

The core part of metal laser welding machine is mainly composed of laser and optical fiber. Fiber lasers have the advantages of high efficiency, stability, and long life, while CO2 lasers have the advantages of high power and fast welding speed.

how does a laser welder work

portable handheld metal laser welding machine video

laser welding machine for stainless steel video

mini small laser welding machine video

dowell laser machine

How much does a handheld portable laser welding machine cost?

There are many brands in the laser welding market, and the price is generally around 6,000-10,000 US dollars. The specific price can vary according to configuration, welding material, brand awareness, after-sales service, etc.

Hand held laser welding machines are assembled by professional technicians, debugged, tested, and shipped only after the product is qualified.

Dowell laser welding machine often participates in overseas exhibitions, such as South Korea, Egypt and other regions, and is deeply favored by customers. We have complete domestic suppliers to meet your customized needs.

Dowell fiber laser welder manufacturers

Dowell laser 15 years of laser equipment manufacturing experience, we can provide the most affordable laser welder price, customized 1000w 1500w 2000w 3000w to meet your welding needs for steel plates, and shipped with welding instructions, more convenient for your use.

FAQ about laser welding system

how thick can a laser welder weld

The handheld fiber laser welding machine can weld materials with a thickness of about 7mm, which is related to the welding power, welding material and welding speed.

what is the best laser welder for jewelry

The choice of jewelry laser welding machine should be based on your own budget, the welding material and the specific welding method to choose, and many for comparison.

how to become a laser welder

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

laser welder vs mig

Laser welding: Uses a highly focused laser beam to heat and melt materials, creating precise and controlled welds. MIG welding: Involves feeding a consumable electrode wire through a welding gun, which melts and fuses with the base material. Heat source:

what is the best laser welder for jewelry

Lorem

how to become a laser welder

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

china handheld laser welder manufacturers

If you want to get the latest handheld laser welding machine price, consult us

We have been a professional laser equipment manufacturer for 15 years. Before shipping, we have professional quality inspectors to test the equipment, technicians debug the welding equipment, and then the shipping department packs the equipment in good condition and finally ships it.