In modern manufacturing, laser cutting technology has become an indispensable processing method. Especially in the field of pipe cutting, 2D and 3D laser cutting technologies each have their own unique advantages and application scenarios.

This article will explore the differences, advantages and disadvantages, and applicable occasions of these two technologies in depth to help you choose the laser cutting solution that best suits your project.

What is 2D Laser Cutting?

2D laser cutting refers to laser cutting on a flat surface, usually used to process flat materials or simple-shaped tubes. This technology uses a laser beam to cut along a preset path, and is suitable for straight and simple curved shapes.

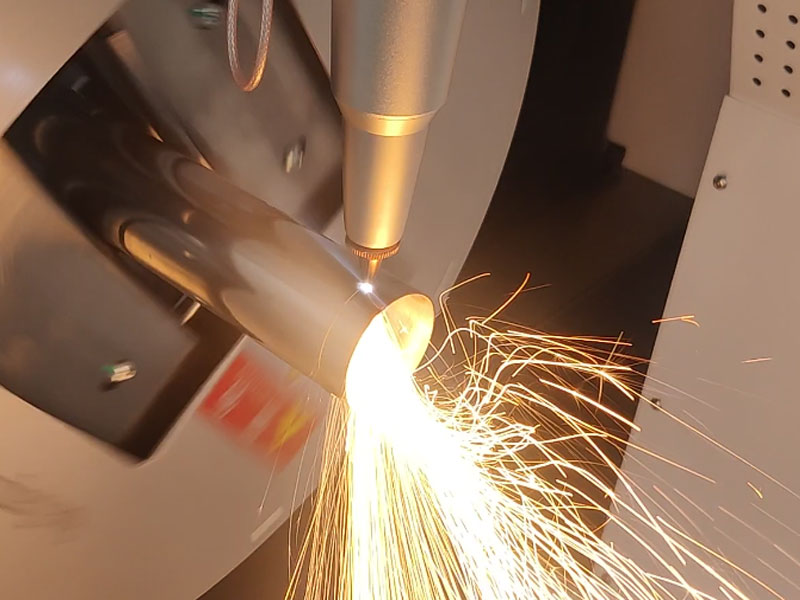

What is 3D Tube Laser Cutting?

3D laser cutting is a more advanced technology that can cut tubes in three dimensions. This technology is capable of processing complex geometric shapes, including curves, bevels, and multi-angle cutting.

2D VS 3D Tube Laser Cutting Pros and Cons

2D Tube Laser Cutting Advantages

Cost-effectiveness

2D laser cutting equipment is usually cheaper than 3D equipment, suitable for small businesses or startups with limited budgets.

Easy to operate

Since the technology is relatively mature, operation and maintenance are relatively simple, many workers can quickly get started.

High speed

For cutting simple shapes, 2D laser cutting can usually achieve faster processing speeds.

2D Tube Laser Cutting Disadvantages

Shape restrictions

2D laser cutting is mainly suitable for flat surfaces and simple shapes, and has limited processing capabilities for complex three-dimensional shapes.

Lack of flexibility

When processing complex designs, multiple cutting and repositioning are required, which may cause time delays and material waste.

3D Tube Laser Cutting Advantages

High flexibility

3D laser cutting can easily handle complex designs and is suitable for projects that require a high degree of customization, such as automotive parts, aerospace components, etc.

Reduce processes

Complete the cutting of complex shapes in one go, which can reduce multiple setup and processing steps, thereby improving production efficiency.

Less material waste

Precise cutting paths reduce material waste and help reduce production costs.

3D Tube Laser Cutting Disadvantages

High equipment cost

3D laser cutting machines are usually expensive and have a long payback period.

Operational complexity

The operation and programming are relatively complex and require professional training to master.

Comparison of 2D and 3D Laser Cutting

| Fonctionnalité | Découpe Laser 2D | Découpe Laser 3D |

|---|---|---|

| Coût | Inférieur | Plus haut |

| La flexibilité | Limited | Highly flexible |

| Operating Difficulty | Simple | Relatively complex |

| Vitesse de coupe | Fast | Relatively slower |

| Utilisation des matériaux | Inférieur | Plus haut |

| Application Scenarios | Simple shapes | Complex geometries |

2D and 3D Laser Cutting: How to Choose

Limited Budget: If you have a limited budget and only need to process simple shapes, then 2D laser cutting may be the best choice.

Requires a high degree of customization: If your project involves complex designs or requires high-precision three-dimensional shapes, then investing in 3D laser cutting equipment will be more advantageous.

Production scale: For large-scale production, although 3D laser cutting has a higher initial investment, it may save costs in the long run due to its high efficiency and low material waste.

Industry demand: Some industries (such as aerospace and automotive manufacturing) have high requirements for precision and complexity, so they prefer to use 3D laser cutting technology. For some traditional manufacturing industries, 2D laser cutting is still the mainstream choice.

Conclusion

Whether you choose 2D or 3D tube laser cutting technology, you should make an informed decision based on your specific needs. Understanding the advantages and disadvantages of each technology will help you stay ahead in an increasingly competitive market. By making a reasonable choice, you can not only improve production efficiency, but also ensure product quality and bring greater success to your business.