industrial laser cleaning machine

what is laser cleaning

Laser cleaning machine, also known as laser rust removal machine, laser rust removal gun, laser blasting machine, laser derusting machine, is used to remove oxides, coatings, and rust on metal surfaces. It is hand-held and portable, and is simple and convenient to operate. It is used frequently in the industrial market.

how does laser cleaning work

Product Advantages

8 Reasons to Choose High Cost Effective Equipment from Dowell Laser

-

The pulse laser used in the laser cleaning machine has a long service life, usually up to 100000 hours, with stable quality and good reliability

-

Suitable for handheld and robotic cleaning operations, with 8 waveform options and universal wheels for easy movement. Strong practicality, covering low power.

-

Through strict certification and testing, the stability of the equipment is ensured, and there is no electromagnetic interference during operation. It is comfortable to buy and reliable to use

-

Dozens of processes are strictly controlled, and each equipment is qualified before leaving the factory. At the same time, we provide customers with protective goggles and core spare parts.

-

The laser cleaning process does not require consumables, does not generate waste, and does not cause environmental pollution during cleaning. High cleaning efficiency, saving time.

-

Providing a complete after-sales service guarantee, Dowell Laser will conduct regular annual follow-up visits to all customers and provide technical support services at any time.

Portable Laser Cleaning Machine Meet Your Requirements

Backpack Style

Collection

Pull rod Type

Collection

Handcart Type

Collection

Small Size

Collection

Portable Type

Collection

Cheaper Type

Collection

Service Support, we do care for our user

Provide customers with more specialized and personalized customized metal fiber laser cleaning services.

Lazer cleaner configuration

laser rust removal gun

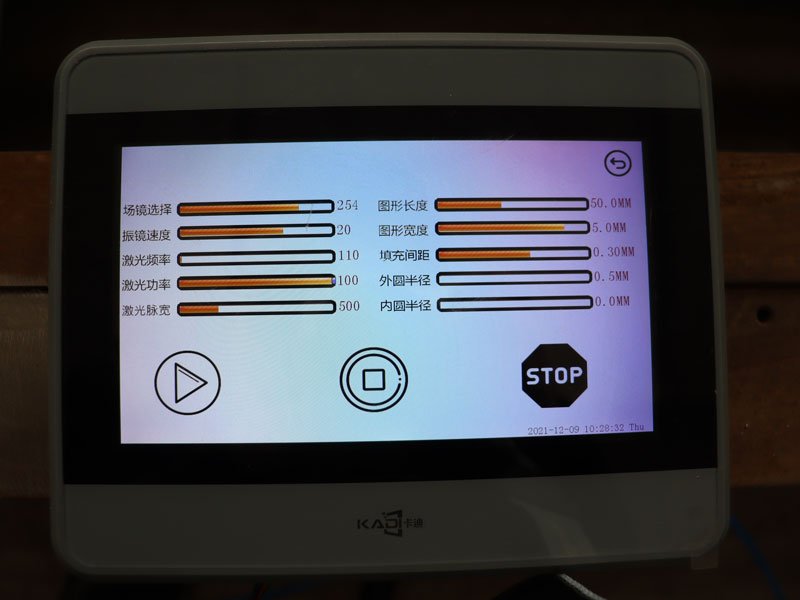

The scanning system is used to control the movement of the laser beam on the surface of the cleaned object.

The laser beam is fixed and stationary through a scanning mirror for scanning. The function of the scanning system is to evenly cover the entire cleaned surface with the laser beam, in order to achieve thorough cleaning.

laser clean systems

The control system is the brain of the entire laser cleaning machine, used to control the operation of the laser, optical system, and scanning system work. The control system can adjust parameters such as laser power, laser beam diameter, scanning speed, etc. according to the actual situation, to achieve different types of cleaning tasks.

fiber-optic laser

Laser is the core component of laser cleaning machines, and commonly used lasers include solid-state lasers, semiconductor lasers, and fiber laser, etc. The laser has high output power, good wavelength selectivity, and good repeatability, making it suitable for calibration

Face cleaning.

How Much Does Laser Cleaning Cost

1000W 2000W 3000W industrial laser cleaner for sale, the price according to the brand, power, welding metal steel, stainless steel, carbon steel, aluminum, brass and other materials, the price cost is also different, laser cleaning machine price in $6000 - - $10000, specific needs to refer to the configuration or consult the laser cleaning machine manufacturer.

laser cleaning tool Features

1. Green and environmentally friendly, no chemical reagents required, small size, easy to store, recyclable, no environmental pollution problems;

2. The laser cleaner machine is non-abrasive and non-contact and will not produce secondary pollution.

3. Achieve remote operation and ensure the safety of operators;

4. Remove contaminants from the surface of various materials to achieve a level of cleanliness that cannot be achieved by conventional cleaning. Without damaging the material surface, selectively clean the pollutants on the material surface;

5. Laser cleaning is highly efficient and saves time;

6. Lazer rust remover can be used stably for a long time and has low operating costs.

Application scope:

1. Rust removal from metal surfaces

2. Surface paint removal and paint removal treatment

3. Clean surface oil, stains and dirt

4. Surface plating and coating are clear

5. Pretreatment of welding surface and spraying surface

6. Remove dust and attachments on the surface of stone statues

7. Cleaning of rubber mold residues

8. Antiques and cultural relics cleaning

It is used in laser cleaning processes such as laser rust removal, oil removal, paint removal, zinc removal, laser film removal, and coating removal on the surface of workpieces. It is widely used in aerospace, molds, microelectronics, construction, nuclear power plants, automobile manufacturing, medical care, and cultural relics. In the fields of protection, military industry, shipbuilding, petroleum, transportation, etc., we undertake laser cleaning and processing business.

Laser cleaning rust removal VS other cleaning rust removals

After comparison, laser cleaning is more preferred for rust removals.

Rust Removal Method

Laser Cleaning

Industrial Cleaning

Mechanical Cleaning

Dry Ice Cleaning

Common and Comparative Points

Cleaning Method

Non-contact Type

Contact-type

Contact-type

Contact-type

Workpiece Damage

None

Have

Have

Have

Cleaning Efficiency

Haut

Faible

Faible

Medium

Material Cost

Just need to power on

Chemical Cleaning Agent

Sandpaper, Grinding Wheel

Dry Ice

Cleaning Effect

High Cleanliness

Generally, Uneven

Generally, Uneven

Excellent, Uneven

Environmental Protection

Pollution-free

Polluted the Environment

Polluted the Environment

Pollution-free

Manual Operation

Easy to Operate

Complex Process

Consuming Manpower

Easy to Operate

Handheld or Automated

Requirements for Operators

Protective Measures need to be Taken

Handheld or Automated

FAQ

Questions about metal laser rust removal and cleaning

Lazer cleaner can not only clean but also remove rust, remove oxides, metal surface coatings, wood stain remover

The workpiece contaminants that need to be cleaned include rust, paint, and concrete residue. If you use laser gun rust removal directly to clean, the effect will be very poor.

The laser rust removal machine uses a continuous fiber laser with a wavelength of 1064nm. This wavelength of laser mainly works on rust layers and metal substrates, and has a low absorption rate on paint and concrete residues. Because the pollutants are different, the cleaning logic is different. The pollutants mainly include paint, rust layer, and cement. Therefore, the best way is to clean in three steps.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation.

Because each manufacturer produces the configuration, branding impression, welding effect is different, the top famous manufacturer supplier, laser rust removal price is relatively expensive, but relative to the cost savings, the investment cost is still appropriate.

Laser rust removal machines for sale on the market generally have different powers such as 100w 200w 500w 1000w 1500w 2000w 3000w. Choose the appropriate laser cleaning and rust removal machine according to the format size of the laser cleaning plate. You can also consult the laser cleaning machine manufacturer to obtain it.

Handheld laser cleaner for wood operation will generate high-energy heat, operators need to do a good job of safety protection, wearing laser goggles, safety masks, etc

When the laser irradiates the metal surface, the dirt on the surface will absorb the energy of the laser and react to loosen it. During the cleaning process, the laser will produce extremely strong vibrations. This vibration will directly shatter the loose dirt, thereby achieving the purpose of rust removal. Effect.

Clients & Partners List

3000+Valued Clients

we work in close relationship with our clients to guarantee that all design needs are satisfied in a timely manner. Our specialists and engineers work closely together to produce tailor-made solutions that match the industry evolving needs.