6000w-12000w Cantilever China CNC Laser Profile Cutting Machine for Sale

The entire set of CNC laser profile cutting machine covers an area of 30000mm×10000mm, of which the cutting station length is 2000mm and the feeding conveyor roller is 14000mm, ensuring the maximum raw material cutting of 12000mm.

description

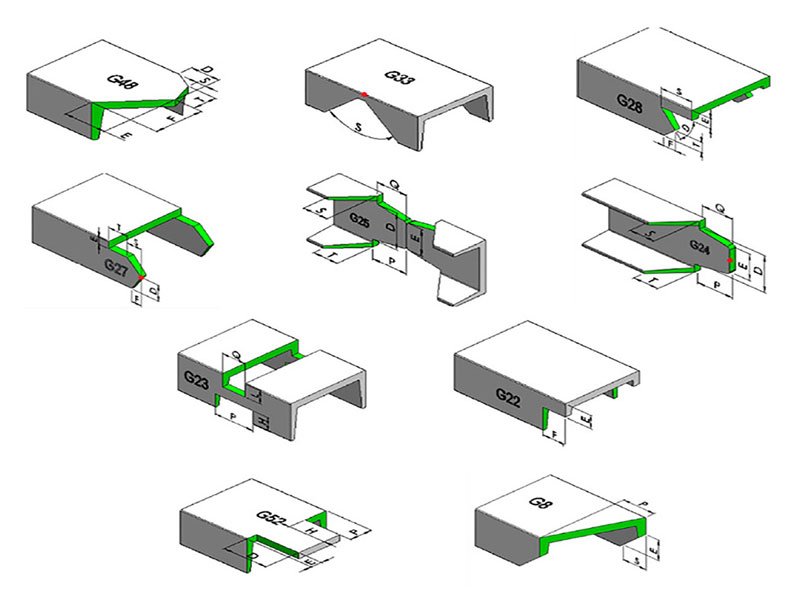

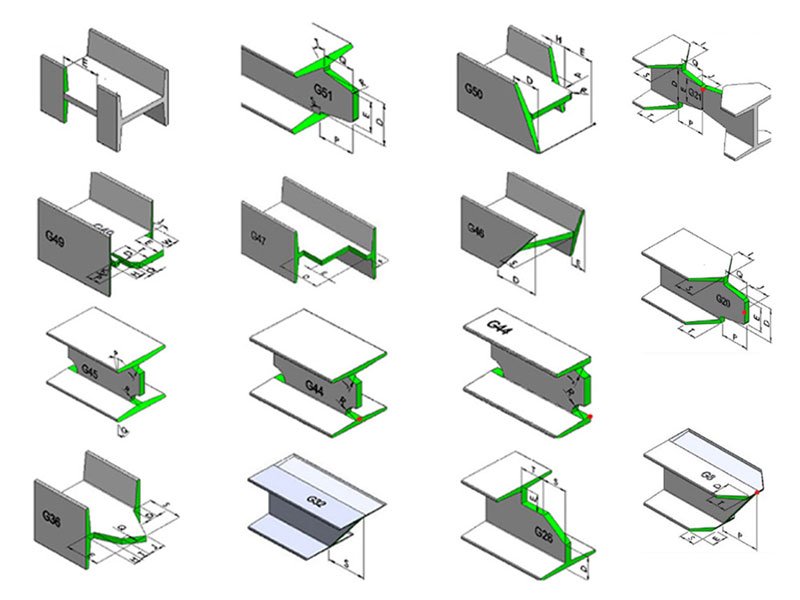

H steel profile laser cutting machine guarantees cutting quality, fast speed, high precision, neat and round edges, smooth and burr-free, and the graphics are not restricted, and complex graphics can be cut. Bevel cutting, groove, truncation, bolt holes, and through-weld holes are processed in one process.

Product features:

- Adopting cantilever open structure, convenient for loading;

- Dual station design, while one station is cutting, the other station can be hoisted and unloaded synchronously, saving loading and unloading time;

- Flexible processing, can be processed in sections or in full length.

Process flow:

Manual overhead crane loading (two pieces at a time) — Material search, centering, contour detection (station one) — Cutting (station one) —– Material search, centering, contour detection (station two) —- Cutting (station two) —- Manual loading and unloading at the same time (station one) — Reciprocating cycle

laser profile cutting machine

The double-station design allows for cutting while loading and unloading.

Technical Parameters

- Brand: Dowell Laser

- Cutting method: laser cutting

- Power: 6000w - 30kw

- H-beam, I-beam, width 100mm-1000mm, height 100mm-500mm.

- Workpiece length: L≤ 12000mm, support customization

- Maximum processing pipe length: 12500mm

- Part cutting form: fixed length straight cutting, fixed length oblique cutting and end socket function.

- bevel cutting: ±45 degrees

- X, Y axis positioning accuracy: ±0.10mm/m

- X, Y axis repeat positioning accuracy: ±0.05mm

- Cutting thickness: perforation cutting 1-40mm

- Maximum moving speed: X axis: 15m/min, Y, Z axis: 30m/min

- Shortest tail length: zero tail

- Cutting scenarios: web, wing plate cutting, bevel, welding hole, bolt hole, marking, etc.

- Floor space: 18000×6000×4500mm (whole machine)

cnc laser profile cutting machine cutting video

cnc laser profile cutting machine video

china cnc laser profile cutting machine factory

Configuration details

- CNC laser profile cutting machine host: DOWELL LASER

- Fiber Laser: MAX Laser

- Cutting head: Precise

- CNC laser profile cutting machine host: DOWELL LASER

- CNC system: DOWELL

- Electronic proportional valve: Anvotech

- Making software: DOWELL

- High-precision disc reducer: Motoroli

- High-precision helical rack: YYC

- Linear guide: TBI/HIWIN

- Laser-specific chiller: Teyu

- Height adjuster: Hongyuda

- Host servo drive and motor: Huichuan

- Regulated power supply: Domestic matching

Cutting effect

laser cutting machine uses application

- Profile laser cutting machine can cut various building materials, such as steel structures, steel plates, profiles, etc., and is widely used in various fields of the construction industry.

- Construction industry: CNC laser profile cutting machine can cut various building materials, such as steel structures, steel plates, profiles, etc., and is widely used in various fields of the construction industry.

- Aerospace industry: Laser profile cutting machines can cut aerospace equipment, such as aircraft wings, rocket engines, etc., and are indispensable equipment in the aerospace industry.

- Engineering machinery manufacturing industry: Aluminum profile laser cutting machine can cut various engineering machinery parts, such as track plates, tires, etc., and is an indispensable equipment in the engineering machinery manufacturing industry.

How Much is laser profile cutting machine price

The price of a laser profile cutting machine can vary widely based on several factors, including the type of machine, its power, the materials it can cut, and additional features. If you want to buy the most affordable and cheapest equipment, you can consult us.

dowell laser profile cutting machine manufacturers

FAQ

Laser profile cutting machines can cut a wide variety of materials, including:

Metals:

- Mild steel

- Stainless steel

- Aluminum

- Brass

- Copper

Other materials:

- Carbon steel

- Spring steel

- Silicon steel

- Iron and alloys

- Gold

- Silver

The control system of the main cutting station of the profile cutting production line mainly includes a multi-dimensional industrial computer, an I/O module, a Hongyuda height controller, 5 sets of absolute encoder servos and external sensors. The cutting program download is completed through the DOWELL BEAM CUTTING control software, and the multi-axis linkage control is completed to realize the cutting of various processes at the end of the profile.

DOWELL system is an industrial computer developed based on Windows system. It uses dual-core processor and runs fast. The core processing speed of motion control, PLC and HMI can reach up to 0.5ms.

Cantilever open structure, convenient loading and unloading.

Hollow steel plate welded body, convenient for heat dissipation, increasing the service life of the equipment, high-strength steel plate welded structure, multiple reinforcing ribs, super rigidity; intermittent welding to ensure welding accuracy and rigidity, while preventing welding deformation; post-weld annealing to remove welding stress; high-precision CNC gantry machining center processing to ensure high precision of processing dimensions.

- It is composed of a frame, blade, etc., and carries the steel. The material is loaded by a manual overhead crane, and the blade side position is positioned by reference.

- Double-station design, while one station is cutting, the other station can be hoisted and unloaded synchronously, saving loading and unloading time;

- Flexible processing, can be processed in sections or full length.