Laser cutting tubes are a remarkable feat of contemporary manufacturing, showcasing a blend of artistry and meticulousness. The seamless integration of materials and technology in this technique is nothing short of amazing, with each material presenting distinct advantages and obstacles.

What Is Laser Tube Cutting?

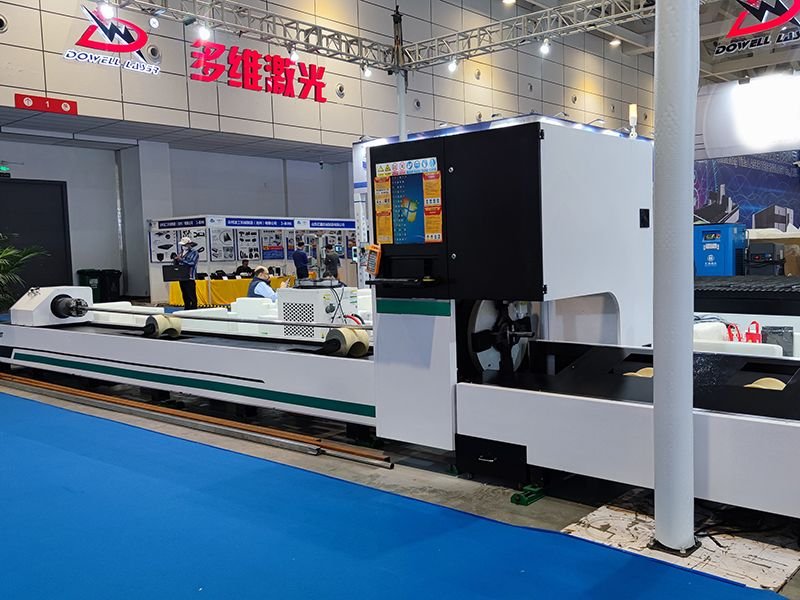

Laser tube cutting is a precise and efficient method used to cut various materials such as steel, aluminum, and stainless steel with high accuracy. In tube laser cutting machine, a laser beam is focused on the surface of the material, melting or burning through it to create clean and precise cuts.

This process is ideal for industries requiring intricate and complex designs as it allows for customization and versatility in cutting different tube shapes and sizes. Additionally, fiber laser tube cutting provides minimal material waste, making it a cost-effective solution for manufacturing industries looking to optimize production processes.

The Basics: How Tube Laser cutting Works

Tube laser cutting works by using a high-powered laser beam to cut through various materials with precision. The process involves focusing the laser on a specific area of the tube, melting or burning through it to create the desired shape. This method is highly efficient and accurate, making it suitable for a wide range of materials.

When it comes to materials suitable for laser tube cutter applications, various options are available. Metals like steel, aluminum, and copper are commonly used due to their durability and versatility. Additionally, non-metal materials such as plastics and ceramics can also be cut using tube cutting machines technology. This flexibility makes tube laser cutting a popular choice for industries requiring intricate and precision laser cutting solutions.

Metal types that use tube laser cutting

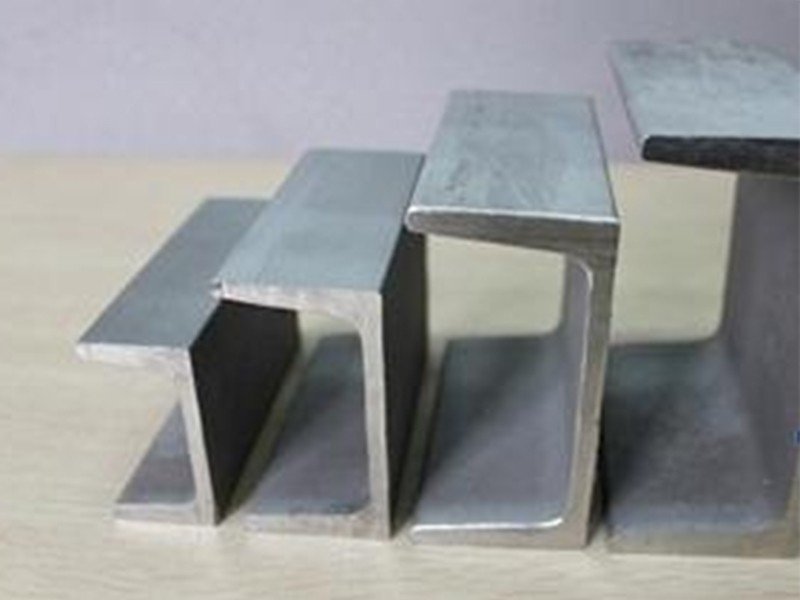

When it comes to tube laser cutting, various metal types can be efficiently processed. It can cut round tubes, square tubes, angle steel, channel steel, rectangular tubes, circular tubes, and oval tubes.

Tube laser cutting application fields

Tube laser cutting finds extensive application in various fields such as automotive, aerospace, and construction industries. The precision and efficiency offered by tube laser cutting make it an ideal choice for fabricating complex components with high accuracy. In the automotive sector, tube laser cutting is widely used for producing exhaust systems, chassis components, and roll cages.

Moreover, in the aerospace industry, tube laser cutting plays a crucial role in manufacturing aircraft components like fuselage sections, wing spars, and landing gear parts.

In the construction field, tube laser business is employed to create structural elements such as steel beams, pipes, and trusses with intricate designs.

The versatility and speed of tube laser cutting machines make it a preferred method for enhancing productivity and achieving superior quality in various industrial applications.

Laser Tube Cutting Material

When it comes to tube laser cutting, the choice of materials plays a crucial role in the process. Different materials offer varying levels of precision and efficiency during laser cutting. Metals like stainless steel, aluminum, and carbon steel are commonly used for tube laser cutting due to their durability and ease of manipulation. These materials ensure clean and accurate cuts, making them ideal for intricate designs and precise measurements.

Materials like copper and brass can also be suitable for tube laser cutting, offering unique aesthetic qualities and corrosion resistance. Understanding the characteristics of each material is essential for achieving the desired results in tube laser cutting projects.

By selecting the right material based on specific project requirements, the efficiency and effectiveness of tube laser cutting can be maximized for optimal outcomes.

Steel: The Backbone of Tube Laser Cutting

Steel is the backbone of tube laser cutting services due to its durability and versatility. When it comes to tube laser cutting, steel stands out as one of the most suitable materials, offering high precision and clean cuts. The efficiency of tube laser cutting services is greatly enhanced by utilizing steel, as it ensures consistent and accurate results.

Choosing steel for tube laser cutting projects guarantees optimal performance and cost-effectiveness. The superior strength of steel makes it ideal for various applications, from manufacturing to construction. With tube laser cutting services tailored for working with steel, intricate designs and complex shapes can be effortlessly achieved, making steel the preferred choice for those seeking top-notch quality and reliability in their projects.

Aluminum: Lightweight Versatility in Fabrication

Aluminum, known for its lightweight properties, is a versatile material extensively used in tube laser cutting processes. Its low density makes it easy to handle, perfect for intricate designs and precise cuts required in tube laser cutting applications. Aluminum’s malleability allows for complex shapes and configurations to be effortlessly fabricated through tube laser cutting, meeting various project requirements with ease.

In tube laser cutting, aluminum stands out for its excellent heat conductivity, which results in clean and smooth cuts without distortion. This property is crucial in maintaining the structural integrity of the cut tubes. Furthermore, aluminum’s corrosion resistance makes it a durable choice for applications exposed to harsh environments, ensuring longevity and reliability in diverse industries utilizing tube laser cutting technology.

Exotic Alloys: Unleashing Innovation and Creativity

Exotic alloys play a pivotal role in the realm of tube laser cutting, providing a canvas for innovation and creativity to flourish. These unique materials, with their exceptional properties and durability, open up new avenues for intricate designs and precise cuts. In the world of tube laser cutting, where accuracy is paramount, exotic alloys stand out as the go-to choice for pushing boundaries and achieving unparalleled results.

From titanium to inconel, the versatility of exotic alloys in tube laser cutting is unmatched. Their ability to withstand high temperatures and harsh conditions makes them ideal for intricate designs and complex geometries. With exotic alloys, manufacturers and designers can unleash their creativity, crafting products that stand out for their durability and precision in the competitive landscape of tube laser cutting.

How thick and thin can Laser Tub Cutting cut?

The thickness of the pipe laser cutting metal pipe is related to the laser power used and the laser cutting head. Different pipe thickness, hardness, thermal conductivity and other factors play an important role in the cutting process, so the power of the selected equipment is different.

What diameter can laser cut pipe ?

The diameter of pipe that a laser can cut will depend on the specific laser cutting machine being used.

When cutting metal pipes, tube laser operators can generally cut 20mm-200mm.Customized equipment, the maximum tube can reach 600mm.

However, in general, laser cutting machines can cut pipes with diameters ranging from as small as a few millimeters to several meters. The precise capabilities of a laser cutting machine for pipe cutting can be determined by consulting the specifications provided by the manufacturer.

How to Choosing Materials for Tube Laser Cutting

Material and tube laser cutting process compatibility.

Materials such as stainless steel, aluminum, and carbon steel are commonly used for their excellent cutting quality and versatility. These materials allow for intricate designs and precise cuts, making them ideal for a variety of industries.

The thickness of the material.

Thicker materials require more laser power and longer processing times. Understanding a material’s thickness capabilities is key to optimizing the tube laser cutting process to increase efficiency and cost-effectiveness.

By carefully considering material compatibility and thickness, you can ensure a successful tube laser cutting operation that meets your specific requirements.

Cost : Material for Tube Laser Cutting

When it comes to cost analysis for tube laser cutting, selecting the appropriate material is crucial. Factors like material thickness, composition, and desired outcome play a significant role in making the right choice. Tube laser cutting works exceptionally well with materials such as stainless steel, aluminum, and carbon steel due to their durability and ease of manipulation during the cutting process.

Understanding the properties of each material is essential for achieving precise and efficient tube laser cutting results. While stainless steel offers excellent corrosion resistance, aluminum is known for its lightweight characteristics.

Carbon steel provides high strength and durability. By carefully evaluating the requirements of your project and the specific characteristics of each material, you can ensure optimal results and cost-effectiveness in tube laser cutting applications.