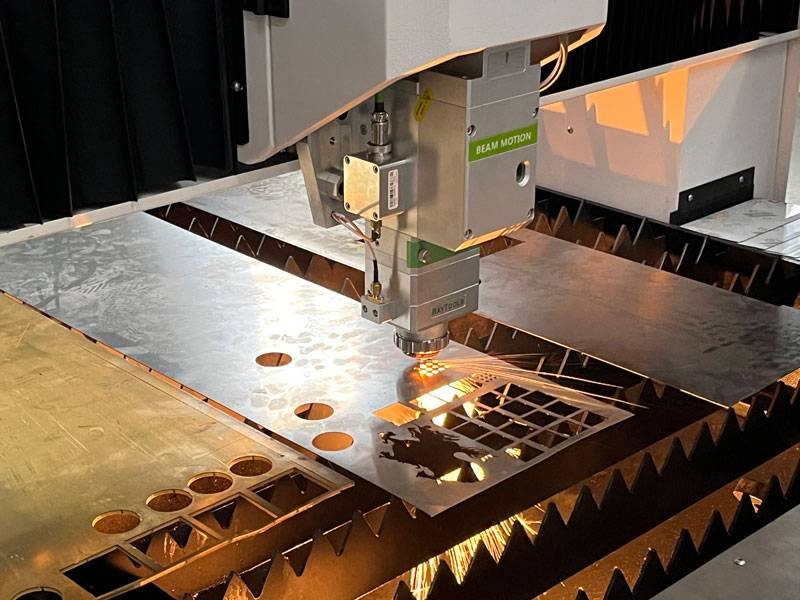

Laser cutting is a precise and efficient method for shaping and cutting materials in various industries, from manufacturing to art. The process involves directing a high-powered laser beam onto a material, which either melts, burns, or vaporizes the target area. One critical aspect of successful laser cutting is selecting the right material, especially one that can effectively reflect heat.

In this article, we will explore the most heat reflective materials for laser cutting and discuss their benefits and applications.

Heat Reflectivity Materialin Laser Cutting

Heat reflectivity refers to the ability of a material to reflect thermal energy instead of absorbing it. In laser cutting, this property is crucial because it affects the material’s response to the laser beam. High heat reflectivity can minimize the risk of overheating, deformation, or damage, ensuring a cleaner and more precise cut.

Most Heat Reflective Materials for Laser Cutting

1. Aluminum

Aluminum is widely regarded as one of the most heat-reflective materials available. Its natural reflectivity can reach up to 95% for infrared and visible light, making it an excellent choice for laser cutting applications. The benefits of using aluminum include:

- High Reflectivity: Reduces heat absorption, preventing thermal damage.

- Lightweight: Easy to handle and maneuver during the cutting process.

- Corrosion Resistance: Enhances durability and longevity of the finished product.

- Versatility: Suitable for a wide range of applications, from automotive to aerospace industries.

2. Copper

Copper is another material with exceptional heat reflectivity, with reflectivity rates of up to 95% for infrared wavelengths. Its properties make it a preferred choice in specific laser cutting scenarios. Advantages of using copper include:

- Excellent Thermal Conductivity: Quickly dissipates absorbed heat, minimizing the risk of warping.

- High Reflectivity: Similar to aluminum, it helps in maintaining the integrity of the cut.

- Electrical Conductivity: Ideal for applications requiring conductive materials, such as electronics and electrical components.

3. Gold

Gold, while more expensive, offers unmatched heat reflectivity, with rates reaching up to 99% for infrared light. Its superior reflective properties make it a premium choice for specialized laser cutting needs. Key benefits include:

- Superior Reflectivity: Almost no heat absorption, ensuring the highest precision cuts.

- Chemical Stability: Resistant to oxidation and corrosion, maintaining material integrity.

- Biocompatibility: Suitable for medical applications, including surgical instruments and implants.

4. Silver

Silver also boasts high heat reflectivity, similar to gold, making it a valuable material for certain laser cutting projects. Although less commonly used due to cost, its advantages are noteworthy:

- High Reflectivity: Reduces thermal distortion and material degradation.

- Antimicrobial Properties: Useful in medical and sanitary applications.

- Aesthetic Appeal: Often chosen for decorative purposes due to its lustrous finish.

Applications Of Heat Reflective Materials In Laser Cutting

The choice of material depends on the specific requirements of the laser cutting project. Here are some common applications:

- Electronics: Copper’s conductivity and reflectivity make it ideal for circuit boards and connectors.

- Aerospace and Automotive: Aluminum’s lightweight and durable nature suits parts and components in these industries.

- Medical Devices: Gold’s biocompatibility and precision are essential for surgical tools and implants.

- Jewelry and Art: Silver and gold are often used for intricate designs and high-quality finishes.

Conclusion

Selecting the most heat reflective material for laser cutting can significantly impact the quality and precision of the final product. Aluminum, copper, gold, and silver are all excellent choices, each offering unique benefits for various applications. By understanding the properties and advantages of these materials, you can make informed decisions that enhance the efficiency and effectiveness of your laser cutting projects.

Incorporating the right material not only improves the cutting process but also extends the lifespan and performance of the finished product. Whether you’re in manufacturing, electronics, aerospace, or the arts, choosing the optimal heat reflective material is key to achieving superior results with laser cutting technology.