After purchasing a metal tube laser cutting machine, it is necessary to choose the right tube laser operator, and this position is a very important position in the manufacturing industry.

What is a laser operator

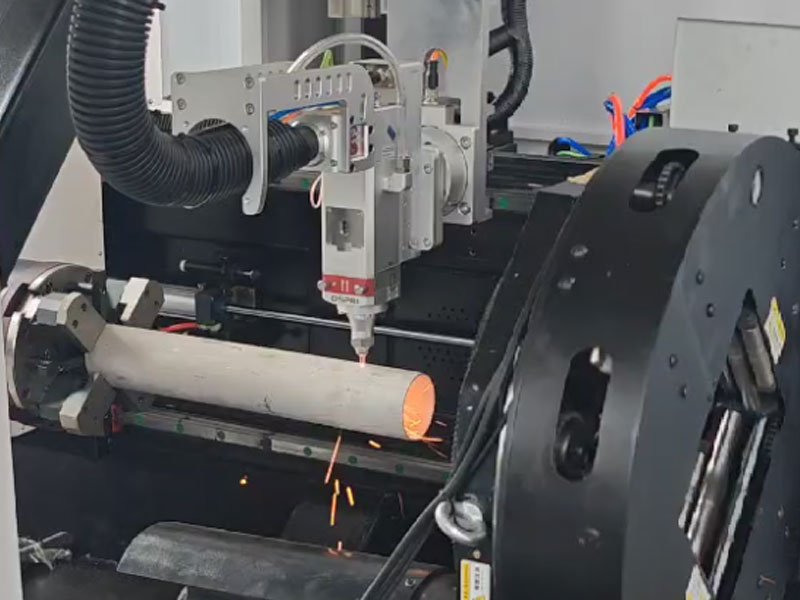

A Tube Laser Operator is a skilled professional who operates and maintains a tube laser cutting machine to process metal tubes into various shapes and sizes. This position is critical in manufacturing industries that rely on precision cutting of tubes to produce products.

Which industries employ cnc tube laser operator position

Tube laser operators are in demand across various industries, including:

- Automotive: Manufacturing car frames, exhaust systems, and other components. Construction: Producing metal framing for buildings and structures.

- Furniture: Creating metal components for chairs , tables, and other furniture items.

- Machinery: Manufacturing parts for industrial machinery and equipment.

- Aerospace: Producing components for aircraft and spacecraft.

What Is a Tube Laser Operator Job Description

- Equipment preparation and startup operation

Check whether the laser tube cutting machine equipment is normal, including the operating status of the optical system, transmission system, etc.

Turn on the laser tube cutting machine equipment and start the machine according to the operating procedures to ensure that the equipment is in normal working condition.

- Workpiece preparation and clamping

Prepare the pipe to be processed according to the process requirements, and clean and measure it.

Clamp the pipe on the workbench to ensure processing accuracy and stability.

- Tool selection and parameter setting

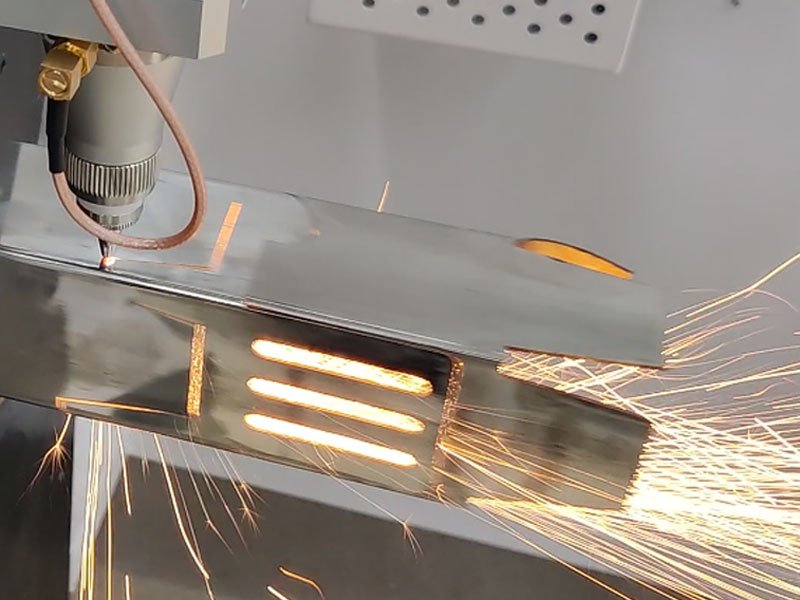

Select the appropriate cutting tool according to the processing requirements, and install and debug it correctly.

Set the processing parameters of the laser tube cutting machine, including cutting speed, power, etc., to ensure that the processing effect meets the requirements.

- Operation control and processing monitoring

Start the laser tube cutting machine equipment, perform processing operations, and pay attention to monitoring the operating status during the processing process.

Adjust the cutting parameters according to the actual situation to ensure processing quality and efficiency.

- Safety and maintenance

Comply with safety operating procedures, pay attention to personal protection, and ensure safety during operation.

Regularly maintain the laser tube cutting machine equipment to ensure long-term stable operation of the equipment.

- Completion and Recording

After completing the processing task, perform workpiece quality inspection to ensure that the processing quality meets the standards.

Record the key parameters and problems in the processing process to provide reference for subsequent work.

In summary, laser tube cutting machine operators need to master equipment operation skills at work, operate strictly in accordance with process requirements, and ensure processing quality and efficiency. At the same time, pay attention to safety and maintenance work, keep records and summaries, and improve work efficiency and quality.

What is the salary of tube laser operator?

Region: Wages in first-tier cities and developed regions are generally higher than in second- and third-tier cities.

Enterprise size: Wages are usually higher in large enterprises, foreign-funded enterprises, or high-tech enterprises.

Work experience: The more experience you have, the higher your salary will be.

Skill level: The more comprehensive the skills mastered, the better the salary.

Industry: The salary level for this position varies by industry.

Generally speaking, the salary level of pipeline laser operators is relatively high, especially if they have strong technical skills and rich experience.