In the laser cleaning market, choosing mopa vs fiber laser is a question that everyone is more concerned about. It is important to understand the difference between the two. This article will focus on mopa laser vs fiber laser. I hope it can help you.

What is a Mopa Laser

Mopa lasers (referred to as main oscillator power amplifier lasers) are laser systems that enable improved pulse duration management.It uses an initial pulse generator to generate the original laser beam, which is then amplified by a power amplifier.

This enhancement process allows for finer adjustment of pulse duration, making it suitable for applications where precise control of laser performance parameters is required.

Industrial pulse laser cleaning machines use mopa lasers.

What is Fiber Laser

A fiber laser is a laser system that uses an optical fiber for the gain medium. In contrast to normal lasers, which employ solid or gaseous media, fiber lasers operate by means of optical fibers that are doped with rare earth elements and generate laser light.

Advantages of fiber laser vs mopa

Advantages of fiber laser

- Excellent beam of light quality produces a focused and concentrated beam of light.

- It is highly efficient in cutting and welding applications.

- Fiber lasers are highly reliable and require minimal maintenance.

Advantages of mopa lasers

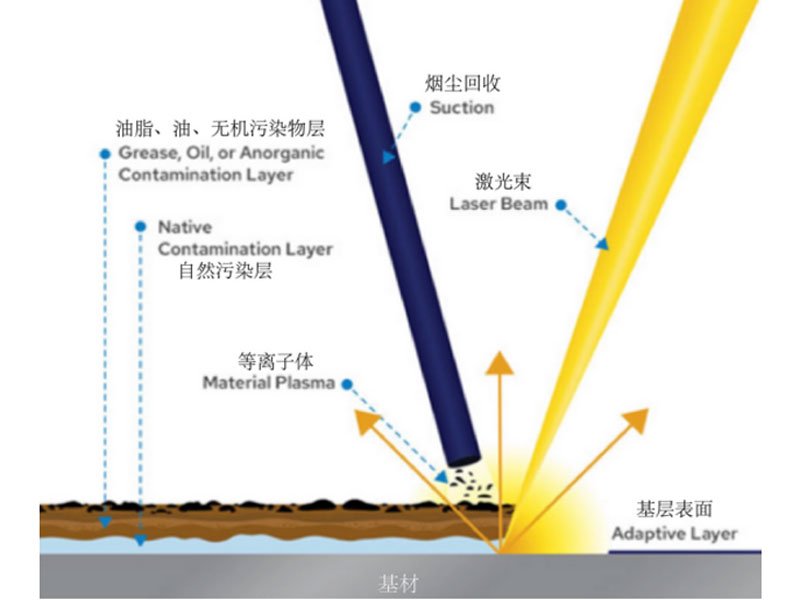

The key benefit is that Mopa lasers have superior control over pulse duration. Laser pulses can be shorter, with less heat applied to the material leading to:

- Sharper Markings and Engravings: Mopa lasers can produce more detailed representations on several materials without much burning or melting at the edges.

- Wider Material Compatibility: As such, controlled heat enables these types of lasers to work well on a greater range of material even including plastics which are sensitive to heat.

- High-Quality Color Marking: Annealing processes that involve metals can be precisely color-controlled by using Mopa laser’s pulse durations.

- Increased Efficiency and Productivity: Consequently, this allows the use of high speed Mopa lasers without compromising marking quality. Time saved in processing thus increases production rate.

- Reduced Heat Affected Zone (HAZ): There are also instances when only a small area will require being affected by a laser beam as little heat is produced during operation. It is important for applications where material integrity must be preserved.

Mopa laser disadvantages

Mopa Laser, like other advanced tools, have some limitations compared to conventional fibre laser:

High Cost: The expense is the major disadvantage. Mopa Lasers are normally more costly than fiber lasers as the technology that controls pulse durations is intricate.

Processing Slightly Slower: Precision is where Mopa Lasers shine, but at times this could be at the cost of speed. For example, they may be slow in cutting thick metallic materials. In contrast with fiber lasers, a typical Mopa laser has low peak power.

Less Availability of High Power Options: Despite being increasingly powerful, high-power ranges may not be easily found for them compared to fiber lasers. On the other hand, if you have an application that requires high power cutting on very thick materials then a better choice would be a fiber laser.

Operation Complexity: The advantage with moppa lasers is that it can offer more control over various parameters for experienced users. However, this also indicates that there may be a learning curve which is steeper when operating them unlike simple fibers.

Differences Between Mopa Laser vs Fiber Laser

| Feature | Mopa Laser | Fiber Laser |

|---|---|---|

| Pulse Duration | Variable | Fixed |

| Heat Affected Zone (HAZ) | Smaller | Larger |

| Material Compatibility | Wider | Narrower |

| Color Marking | Superior | Inferior |

| Cost | Higher | Lower |

| Processing Speed | Slower | Faster |

| Ideal Applications | Intricate marking, engraving, micromachining | Fast cutting of thick metals |

Applications in mopa vs fiber laser

Various industries widely use both Mopa Lasers and Fiber Lasers.

Marking and engraving applications commonly employ Mopa lasers whose pulse duration control allows marking to be done with precision on various materials such as metals, plastics, ceramics, among others. You can find them in sectors like electronics, automobiles production, jewelry manufacture and medicinal products making.

Fiber lasers cut and weld very well. These lasers produce a high-quality beam that enables accurate cutting of different materials like metallic steel or aluminum. They are generally applied in manufacturing plants, automotive companies, aerospace industry and shipyards.

Cost: Mopa Laser vs Fiber Laser

- Mopa Laser: Considered the premium option. The added complexity of controlling pulse duration translates to a higher price tag.

- Fiber Laser: Generally more affordable due to their simpler design and mass production.

Advantages of Mopa Laser in Marking and Engraving

- There is pulse duration control feature. It allows for fine marking of materials, even those which are delicate or prone to destruction. Mopa Lasers can create quality marks with great intricacy that makes them excellent in applications where appearance and accuracy are important.

- The pulse frequency and energy have been made versatile. This means different users can obtain different marking effects like deep etching or surface annealing by changing the laser settings.

- Various things such as metals, plastics, ceramics, glass etcetera could be marked using Mopa Lasers. They are therefore a good choice for many industries and applications.

Conclusion

When selecting the appropriate laser system, it is very important to know the dissimilarities between Mopa lasers and fiber lasers. Precise control of pulse duration for marking and engraving purposes is an area where Mopa lasers stand out. Fiber lasers have excellent beam quality that is ideal for cutting and welding. Therefore, one needs to take into consideration their requirements, budgetary limits as well as what they want to achieve in order to make a realistic assessment that will support strategic objectives of a company.