With the continuous development of market demand, metal tube cutting is becoming more and more popular among business owners. However, for manufacturing companies that cut stainless steel tubes in batches, the traditional laser tube cutting process is relatively complicated, time-consuming, and labor costs are relatively high. However, the emergence of laser bundling line for tube processing can solve this problem well.

What Is Laser Automatic Bundling for Tube Processing

Laser automatic bundling refers to the process of using a high-energy-density laser beam to accurately cut or melt the tubes, thereby achieving automatic bundling.

Laser automatic strapping vs traditional strapping

Laser Automatic Strapping vs. Traditional Strapping

| Feature | Laser Automatic Strapping | Traditional Strapping |

|---|---|---|

| Strapping Material | Plastic or metal | Plastic or metal |

| Securing Method | Laser melting or cutting | Buckles or seals |

| Speed | High speed | Moderate speed |

| Precision | High precision | Moderate precision |

| Labor Requirement | Low (automated) | Medium (manual intervention) |

| Cost | Higher initial investment, lower operating costs | Lower initial investment, higher operating costs |

| Environmental Impact | Generally lower waste | Higher waste due to buckles and seals |

Advantages of Laser Bundling System for Tube Processing

Efficiency improvement: Automated operation has greatly improved the efficiency of bundling, reduced manual intervention, and shortened the production cycle.

High precision: The accuracy of the laser beam guarantees the tightness and consistency of the binding, reducing the rate of product defects.

Flexible: Can adapt to pipes of different sizes and shapes to meet diverse production needs.

Environmental protection: Reduces the waste generated by traditional bundling methods, in line with the concept of green production.

Quality assurance: The binding process is controllable to ensure stable product quality.

Applications of Laser Bundling Line for Tube Processing

Automobile manufacturing: used to bundle automobile parts pipes, exhaust systems, etc.

Furniture manufacturing: used to bundle tubular furniture parts such as sofa frames, table and chair legs.

Construction industry: used to bundle steel pipes, water pipes and other construction materials.

Machinery manufacturing: used to bundle tubular parts of various mechanical equipment.

Electronics industry: used to bundle cables in electronic products.

Aerospace: used to bundle pipeline systems on aerospace vehicles.

Medical device industry: used to bundle tubular components of medical devices.

Food packaging industry: used to bundle food packaging materials.

Need to Use Laser Automatic Bundling for Tube Processing

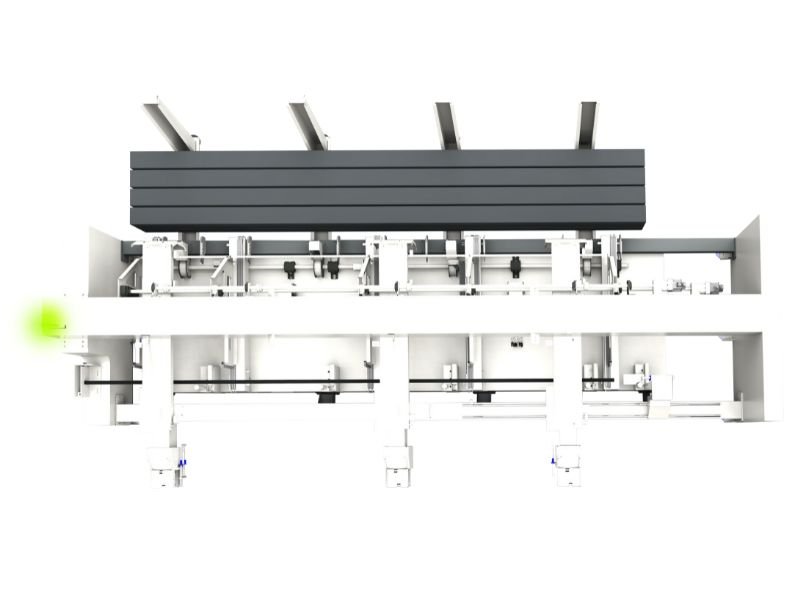

Laser Tube cutting machine: Integrate the laser cutting machine with the automatic strapping module to achieve the integration of cutting and strapping.

Flexible production line: Flexible configuration of laser strapping modules according to different pipe specifications and production requirements.

Automated warehouse: In automated warehouses, laser strapping technology can be used to strap pipes entering and leaving the warehouse.

Special strapping machine: Customized design for specific pipe types and production processes.

Robotic system: Industrial robots can be equipped with laser strapping tools to achieve flexible grasping and strapping of pipes.

Development of laser automatic strapping

With the continuous development of laser technology and the continuous improvement of automation level, laser automatic strapping technology will be applied in more fields. In the future, we can expect laser automatic strapping technology to make greater breakthroughs in the following aspects:

Intelligence: Through the introduction of artificial intelligence technology, a more intelligent strapping process can be achieved.

Diversification: Adapt to more types of materials and complex shapes of pipes.

Integration: Deeply integrated with other processing technologies to achieve full automation of the production process.

Conclusion

As an efficient, accurate and flexible processing method, laser automatic binding technology is leading the pipe processing industry to develop in the direction of automation and intelligence. Through the introduction of this article, I believe you have a deeper understanding of laser automatic binding technology.