In the world of metal fabrication, precision and efficiency are paramount. Among the various tools available, fiber laser cutting heads have revolutionized the industry by offering unparalleled accuracy and speed. Whether you are a seasoned professional or a newcomer to the field, selecting the best fiber laser cutting head is crucial to achieving optimal results.

In this guide, we will delve into the key factors to consider when choosing a fiber laser cutting head and highlight some of the top options available in the market.

What is Fiber Laser Cutting Heads?

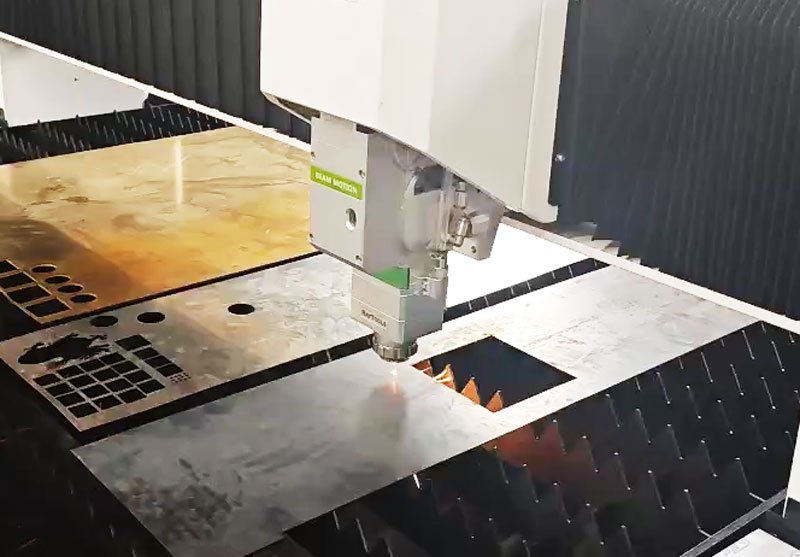

Fiber laser cutting heads are integral components of fiber laser cutting machines, which use high-power laser beams to cut through metals and other materials with exceptional precision.

Benefits of Fiber Laser Cutting Heads

These cutting heads focus the laser beam onto the material, enabling clean and precise cuts with minimal heat distortion. The benefits of fiber laser cutting heads include:

- High Precision: Fiber lasers can achieve incredibly fine and accurate cuts, making them ideal for intricate designs and detailed work.

- Speed: They offer faster cutting speeds compared to traditional cutting methods, increasing productivity and reducing turnaround times.

- Versatility: Suitable for cutting a wide range of materials, including stainless steel, aluminum, brass, and more.

- Low Maintenance: Fiber lasers have fewer moving parts and require less maintenance compared to other types of lasers, resulting in lower operating costs.

How Choose Best Fiber Laser Cutting Head

1. Power Output

The power output of a fiber laser cutting head is a critical factor to consider. Higher power outputs enable faster cutting speeds and the ability to cut through thicker materials. For industrial applications, cutting heads with power outputs ranging from 1kW to 10kW are commonly used. It’s essential to match the power output with your specific cutting requirements.

2. Beam Quality

The quality of the laser beam, often measured by the beam parameter product (BPP), impacts the precision of the cuts. A lower BPP indicates a higher quality beam, resulting in finer and more accurate cuts. For high-precision applications, look for cutting heads with excellent beam quality.

3. Cooling System

Fiber laser cutting generates significant heat, which can affect the performance and longevity of the cutting head. An efficient cooling system is essential to maintain optimal operating temperatures and prevent overheating. Cutting heads with advanced cooling mechanisms, such as water or air cooling, ensure consistent performance.

4. Compatibility

Ensure that the fiber laser cutting head is compatible with your existing laser cutting machine. Compatibility involves not only the physical fit but also the software integration and control systems. Many manufacturers offer cutting heads specifically designed for their machines, ensuring seamless operation.

5. Focus Control

Accurate focus control is vital for achieving precise cuts. Some advanced cutting heads come with automatic focus adjustment features, allowing the laser beam to maintain optimal focus across varying material thicknesses. This feature enhances cutting accuracy and reduces the need for manual adjustments.

Top Fiber Laser Cutting Heads Factory in 2024

1. Precitec ProCutter

The Precitec ProCutter is renowned for its high precision and versatility. With power options up to 15kW, it is suitable for cutting a wide range of materials. The ProCutter features automatic focus adjustment, advanced cooling systems, and compatibility with most industrial fiber lasers. Its robust design ensures durability and consistent performance, making it a top choice for industrial applications.

2. RayTools BM109

RayTools BM109 is a popular choice for both industrial and small-scale applications. It offers excellent beam quality and precise focus control, ensuring high-quality cuts. The BM109 supports power outputs up to 6kW and features an efficient water-cooling system. Its compact design and affordability make it a favored option among fabricators.

3. IPG Photonics LaserCube

The IPG Photonics LaserCube is designed for high-precision cutting applications. With power options up to 4kW, it delivers exceptional beam quality and focus control. The LaserCube’s user-friendly interface and compatibility with various laser cutting machines make it a versatile choice for precision cutting tasks.

4. TRUMPF TruLaser Head

TRUMPF is a well-known name in the laser cutting industry, and the TruLaser Head lives up to its reputation. It offers power outputs up to 12kW and features advanced cooling and focus control systems. The TruLaser Head is compatible with TRUMPF’s range of laser cutting machines, ensuring seamless integration and high performance.

Where to Buy Cheap Fiber Laser Cutting Head

1. Direct from Manufacturers

Buying directly from manufacturers can often yield better prices compared to resellers or distributors. Many manufacturers offer discounts or lower prices for bulk purchases or direct orders.

2. Second-Hand Markets

Used or refurbished fiber laser cutting heads can be significantly cheaper than new ones. Platforms like eBay, Alibaba, and specialized industrial equipment resellers often list second-hand equipment that is still in good working condition.

3. Wholesale Suppliers

Wholesale suppliers or industrial equipment brokers may offer discounts on bulk purchases. Websites like Alibaba and Made-in-China list many wholesale suppliers that can provide competitive pricing.

4. Online Marketplaces

Online marketplaces such as Amazon, eBay, and Alibaba can be good places to find deals on fiber laser cutting heads. These platforms often have a wide range of options and allow for price comparison.

5. Industrial Auctions

Participating in industrial auctions can be a great way to purchase equipment at lower prices. Websites like BidSpotter, Machinery Network Auctions, and Industrial Auctions often feature laser cutting equipment.

6. Local Distributors

Local distributors or dealers might offer competitive prices, especially if they have overstocked inventory or are looking to clear out older models.

Conclusion

Choosing the best fiber laser cutting head requires careful consideration of factors such as power output, beam quality, cooling system, compatibility, and focus control. By selecting a cutting head that aligns with your specific needs and applications, you can enhance the precision, speed, and efficiency of your cutting operations.

The Precitec ProCutter, RayTools BM109, IPG Photonics LaserCube, and TRUMPF TruLaser Head are among the top options available in 2024, each offering unique features and benefits. Evaluate your requirements and choose a cutting head that will help you achieve optimal results in your metal fabrication projects.

Investing in a high-quality fiber laser cutting head is a step towards achieving superior cutting performance and staying ahead in the competitive field of metal fabrication.