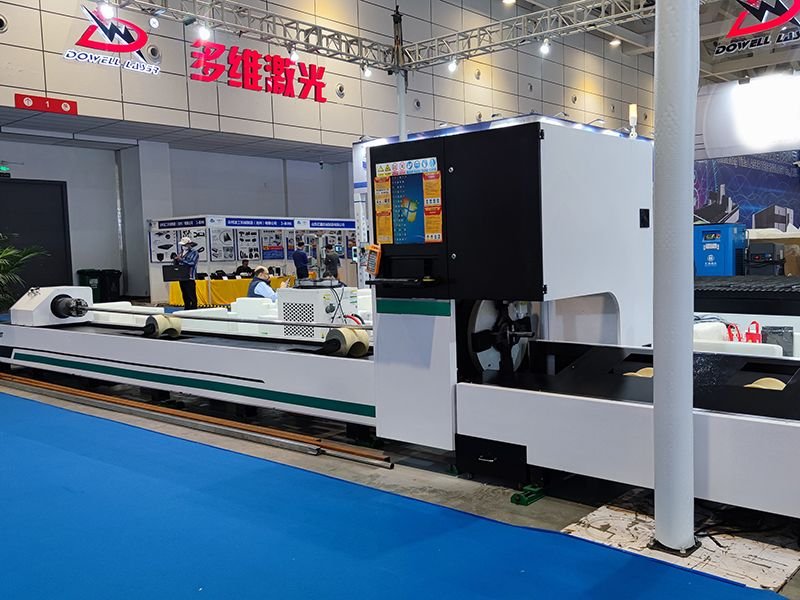

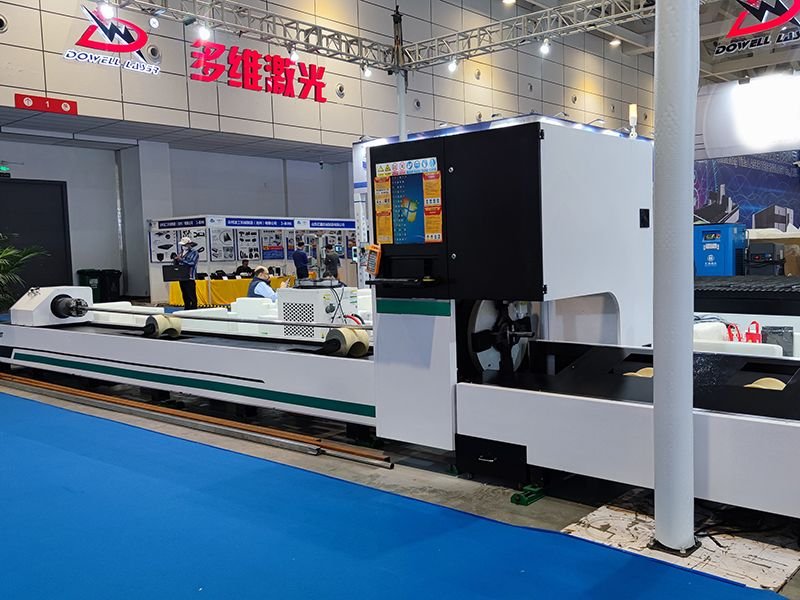

China Aluminum Profile Laser Cutting Machine for Sale

Fiber laser machines are an excellent choice for cutting aluminum profiles due to their high cutting speeds and ability to produce intricate cuts.

It can process round tubes, square tubes, rectangular tubes, oval tubes and other shapes.Can be used with automatic loading and unloading device

description

Aluminum profile laser cutting machine is mainly used for integrated processing of aluminum door and window profiles, including laser cutting, drilling and milling, and 45° and 90° angle cutting;

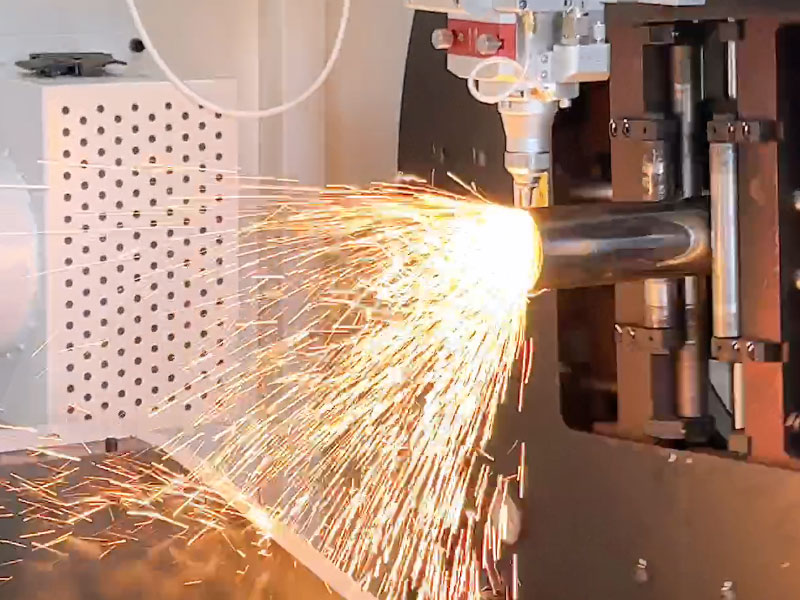

Suitable for cutting carbon steel, stainless steel, aluminum alloy round tubes, square tubes, rectangular tubes, and oval tubes

aluminum laser cutting video

China CNC Laser Profile Cutting Machine Manufacturers

Section steel laser secondary processing line video

Technical Parameters

- Brand: Dowell Laser

- Power: 1000w -12kw

- Cutting method: laser

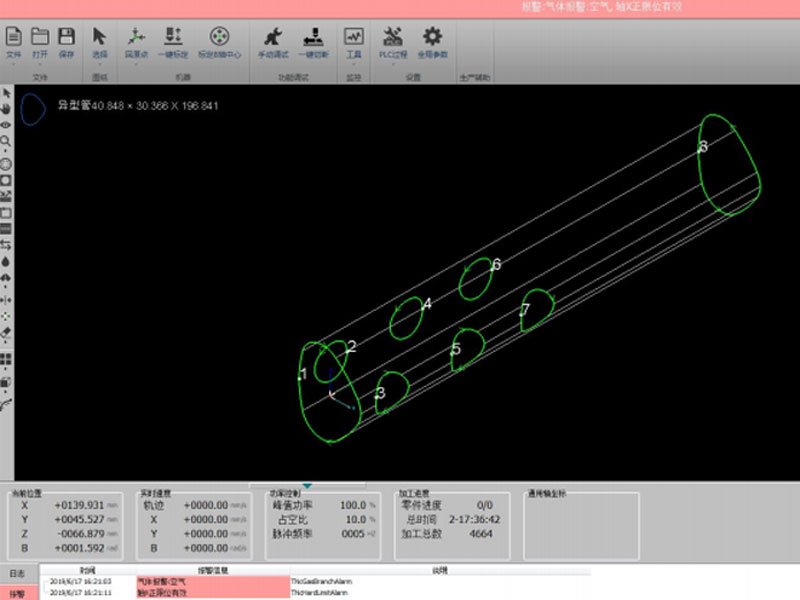

- Round Pipe : φ16 mm to φ80 mm Rectangular Pipe : 16 x 16 mm to 60 x 60 mm (diagonal < 85mm)

- X/Y-axis Positioning Accuracy :±0.03mm/m

- X/Y-axis Repositioning Accuracy: ±0.03mm

- Length of Tube :6000mm

- Bevel cutting: ±45°

- Customizable designs

- Maximum processing wall thickness: 40mm

- Voltage: 380V

- Frequency: 50Hz

- Assist gas:Purified dry compressed air and high purity oxygen (O2) and nitrogen (N2) purity not less than 99.9%

Features

Cutting capabilities:

Fiber lasers can effectively cut aluminum between 1 mm and 25 mm thick.

Higher power lasers (e.g., 10 kW) can cut thicker aluminum with good edge quality.

Cutting speed and quality:

Cutting speed varies depending on material thickness and laser power.

There’s often a balance between cutting speed and cut quality.

Fiber lasers produce small heat-affected zones, resulting in minimal material changes during cutting.

Edge quality:

Good edge quality on aluminum requires balancing various cutting parameters like speed, focal position, and gas pressure.

Thinner materials (up to 4-6 mm) can be cut with virtually no dross, depending on laser power.

Cutting gas:

Nitrogen is commonly used for cutting aluminum, but compressed air can also be used.

Air cutting may result in slightly faster speeds and less dross, but requires a specialized high-pressure compressor.

Configuration details

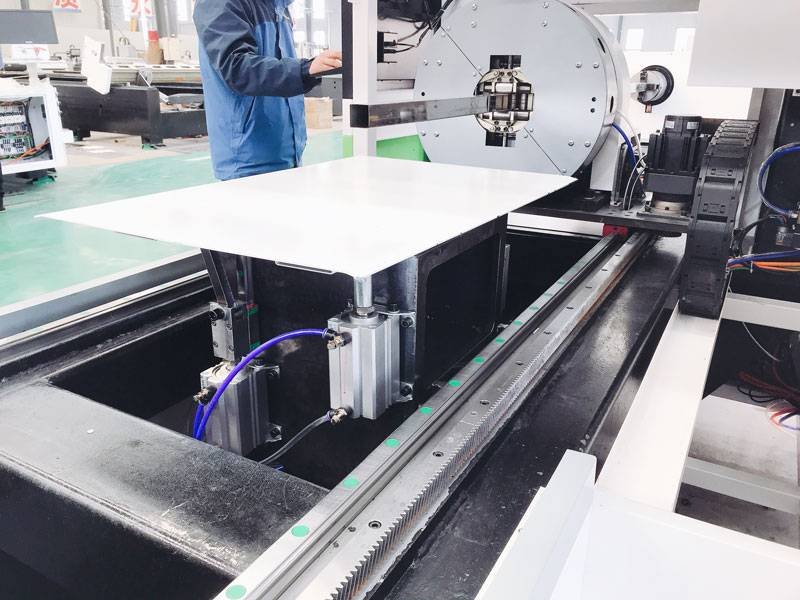

Pneumatic Chucks

Advanced control system, capable of secondary development, using laser sensors for precise control

Autofocus cutting head

Made of stainless steel, with water cooling function, dual-path cooling nozzle, ceramic ring, double focusing protection lens, drawer-type pluggable protection lens, focusing and collimating lens

Short tail cutting

Considering that the smaller the distance between the chuck and the cutting head, the higher the cutting accuracy and the shorter the tail material, it can save costs for users.

Tube cutting system software

Tube cutting system software is specialized CAD/CAM software designed to optimize the process of cutting tubes, pipes, and profiles.

Optional automatic loading and unloading

Each part realizes the whole process of automatic production, including automatic taking, automatic loading and automatic supply of pipe materials, which can effectively ensure product quality, improve production efficiency and reduce production costs.

Bevel cutting ±45°

Supports inclined perforation and accurate positioning after perforation. Straight perforation of some parts will inevitably damage the parts. Through “automatic knife division”, one-knife cutting and multi-knife cutting can be quickly achieved

aluminum profile laser cutting machine price

Do you need to cut a large number of aluminum profiles? Are you considering purchasing a fiber laser machine to meet your production needs? If you want to know the specific aluminum profile laser cutting machine price, you can consult us to get the most affordable price.

Dowell aluminum profile laser cutting machine factory

FAQ

For users who want to buy aluminum profile laser cutting machines, they can find laser cutting machines of various brands, specifications, prices, and related wholesale and promotion information on e-commerce platforms such as Alibaba. At the same time, World Aluminum also provides aluminum profile laser cutting machine products and price information from different manufacturers for users to choose from.

Three categories: CO2 laser cutting machine, fiber laser cutting machine and lamp-pumped laser cutting machine.

When cutting highly reflective materials such as aluminum and copper, CO2 laser cutting machines are limited in practicality because most of the energy is reflected, and the photoelectric conversion rate is low and the cost is high.

Fiber laser cutting machines are more suitable for cutting metal materials, with higher photoelectric conversion rates and lower maintenance costs.

YAG laser cutting machines are also increasingly favored by the market for their mature technology and lower purchase and use costs.

The laser cutting machine parameters need to be adjusted appropriately to achieve precise cutting. Fiber laser cutting machines are particularly effective when cutting aluminum, providing the platform accuracy and superior performance of laser cutting technology.

Cutting efficiency:

Fiber lasers are generally more efficient at cutting aluminum than CO2 lasers. The laser beam energy from fiber lasers is absorbed more efficiently by aluminum surfaces.

Cutting speed:

Fiber lasers can cut aluminum significantly faster than CO2 lasers, especially for thinner materials. A high-powered fiber laser can cut up to five times faster than a conventional CO2 laser.

Material thickness:

Fiber lasers excel at cutting thin aluminum sheets (up to about 5 mm thick).

CO2 lasers perform better on thicker aluminum materials (over 5 mm), providing faster initial piercing times and smoother surface finishes.

Edge quality:

CO2 lasers tend to produce smoother cut edges, especially in materials thicker than 3 mm.

Reflectivity handling:

Fiber lasers can more safely and precisely cut reflective metals like aluminum. The beam from fiber lasers is absorbed more efficiently by aluminum, reducing the likelihood of reflection.

Energy efficiency:

Fiber lasers consume significantly less power than CO2 lasers, resulting in lower operating costs. A high-power CO2 laser may consume around 70 kW at maximum power, while a comparable fiber laser only uses about 18 kW.

Maintenance:

Fiber lasers require less maintenance compared to CO2 lasers. They have no moving parts or mirrors that need alignment, resulting in lower overall maintenance costs.

Initial cost:

CO2 lasers typically have a lower upfront cost compared to fiber lasers.

Precision:

Fiber lasers generally offer higher precision and can produce finer details, making them preferable for applications requiring complex designs.

Fiber lasers are generally more effective than CO2 lasers for handling aluminum alloys, especially for thin to medium-thickness materials. They offer superior energy efficiency, faster cutting speeds, and higher precision. However, CO2 lasers may still have advantages for very thick aluminum materials or when a lower initial investment is desired.