The high precision of laser cutting machines is well known to everyone, but if you want to master this laser cutting process and understand the laser cutting thickness chart, it is very critical to cut the ideal renderings.

If you want to learn about laser cutting thickness chart, this article will be of great help to you.

Laser Cutting: The Basics

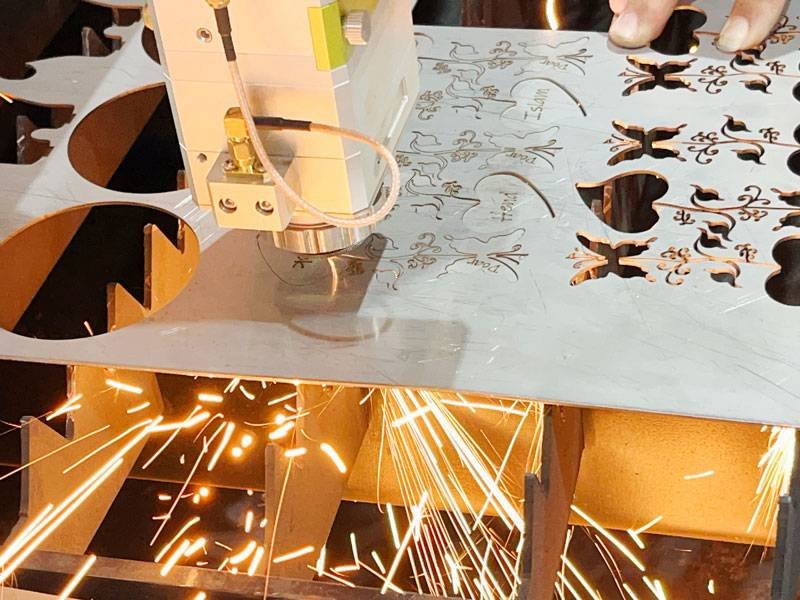

Laser cutting is a versatile and precise method of cutting a variety of materials using a laser beam. It has become an essential tool for designers, allowing them to create complex and detailed designs with ease. In this section, we’ll explore the basics of laser cutting and how it works.

The process of laser cutting involves focusing a high-power laser beam onto the surface of the material to be cut. The intense heat generated by the laser beam melts or vaporizes the material, resulting in a clean and precise cut. The speed and intensity of the laser can be controlled to achieve different levels of precision.

An important factor to consider in laser cutting is the thickness of the material being cut. The thickness of the material determines the power and speed settings required for best results. Different materials have different optimal thicknesses for laser cutting, so a clear understanding of these parameters is crucial.

Importance of Laser Cutting Thickness in Design

The thickness of the material being cut plays an important role in determining the success and quality of your laser cutting design. If the material is too thick, clean cuts or intricate details may not be achieved.

If the material is too thin, it may not be able to withstand the heat generated by the laser beam, causing warping or damage. To ensure your design is executed perfectly, it is essential to refer to the laser cutting thickness chart.

This chart provides valuable information about which materials can be cut to specific thicknesses and helps you choose the appropriate settings for your design project.

Laser Cutting Thickness Chart

The laser cutting thickness chart serves as your guide in navigating through various materials and their corresponding optimal thicknesses for laser cutting. It provides valuable information about which materials can be cut using a specific type of laser cutter and at what power settings.

| Material | Maximum Thickness (mm) |

|---|---|

| Mild Steel | 25 |

| Stainless Steel | 20 |

| Aluminum | 12 |

| Brass | 8 |

| Copper | 6 |

| Acrylic | 25 |

| Wood | 20 |

| MDF | 20 |

| Plywood | 20 |

The chart typically includes information such as material type, recommended thickness range, and power settings. By referring to this chart, you can determine the appropriate laser power and speed settings for your specific design project.

Fiber Laser Cutting Thickness & Power Chart

| Material | Maximum Thickness (mm) | Recommended Power (kW) |

|---|---|---|

| Mild Steel | Up to 25 | 1.5 – 6 |

| Stainless Steel | Up to 20 | 1.5 – 4 |

| Aluminum | Up to 12 | 1.5 – 3 |

| Brass | Up to 8 | 1.5 – 3 |

| Copper | Up to 6 | 1.5 – 3 |

| Acrylic | Up to 25 | 0.5 – 2 |

| Wood | Up to 20 | 0.5 – 2 |

| MDF (Medium Density Fiberboard) | Up to 20 | 0.5 – 2 |

| Plywood | Up to 20 | 0.5 – 2 |

Issues That Need Attention in Laser Cutting

Laser cutting materials

Common materials that can be cut using laser cutting include acrylic, wood, paper, fabric, leather, and some metals. Each material has its own unique properties and requirements for laser cutting. By consulting a laser cutting thickness chart, you can ensure you choose the right material for your design project.

What’s Possible Cutting Capabilities

Laser cutting opens up a whole world of design possibilities. With its super accurate cuts, designers can whip up intricate patterns, detailed shapes, and even throw in some personalized engravings. Seriously, the sky’s the limit with laser cutting. Just get cozy with your laser cutting machine’s capabilities and peek at that handy laser cutting thickness chart. From there, it’s all about unleashing your creativity. Whether you’re dreaming up some custom bling or tackling some fancy architectural models, laser cutting is your go-to for bringing those wild ideas to life with crazy precision.

Design Possibilities:

The precision offered by laser cutting opens up a world of design possibilities. From creating intricate lace patterns on fabric to engraving personalized messages on wooden plaques, there is no limit to what you can achieve with laser-cut designs.By referring to the laser cutting thickness chart, you can push the boundaries of your designs even further. The chart provides valuable insights into how different materials behave at various thicknesses and helps you make informed decisions about your design choices.

Tips and Tricks for Using the Laser Cutting Thickness Chart

- Familiarize yourself with the chart: Take the time to study the laser cutting thickness chart and understand its different sections and parameters.

- Test cuts: Before starting a large-scale project, perform test cuts on different materials and thicknesses to determine the optimal settings for your design.

- Consult with experts: If you are unsure about certain materials or thicknesses, reach out to experts or manufacturers who specialize in laser cutting for guidance.

- Keep the chart updated: As technology advances and new materials become available, make sure to update your laser cutting thickness chart accordingly.

By utilizing the laser cutting thickness chart effectively, you can take your designs to new heights. The chart empowers you to make informed decisions about material selection, power settings, and design possibilities – all of which contribute to creating exceptional and visually stunning pieces.

Conclusion:

Mastering precision in laser cutting is essential for designers looking to elevate their creations. The laser cutting thickness chart serves as a valuable resource that unlocks a world of possibilities by providing insights into material compatibility, cutting capabilities, and design options. By understanding the importance of laser cutting thickness in design and decoding the laser cutting thickness chart, designers can make informed decisions about material selection and optimize their designs for optimal results. With this knowledge at hand, designers can push the boundaries of creativity and create exceptional pieces that leave a lasting impression.

FAQ

What thickness can a laser cutter cut?

The maximum thickness a laser cutter can cut depends on several factors, the type of material being cut, the power of the laser cutter, and other machine specifications. Be sure to consult the manufacturer’s guide or refer to the laser cutting thickness table for specific information on the maximum thickness of different materials.

How much power laser is required to cut 0.2 to 0.3 mm steel plates?

A laser cutter with sufficient power is required to cut 0.2 to 0.3 mm steel plates. The exact power requirements depend on the type of laser cutter and the specific properties of the steel being cut. It is recommended to consult the manufacturer’s guide or refer to the laser cutting thickness table for accurate information on the power requirements for cutting steel plates of this thickness.

How do I choose the power of a fiber laser cutting machine?

The type and thickness of material you plan to cut, your desired cutting speed, and budget considerations. When selecting a fiber laser cutting machine, it is important to consider these factors in conjunction with the manufacturer’s recommendations and specifications. By referring to the laser cutting thickness chart, you can determine the appropriate power range for different materials and make an informed decision based on your specific design requirements.