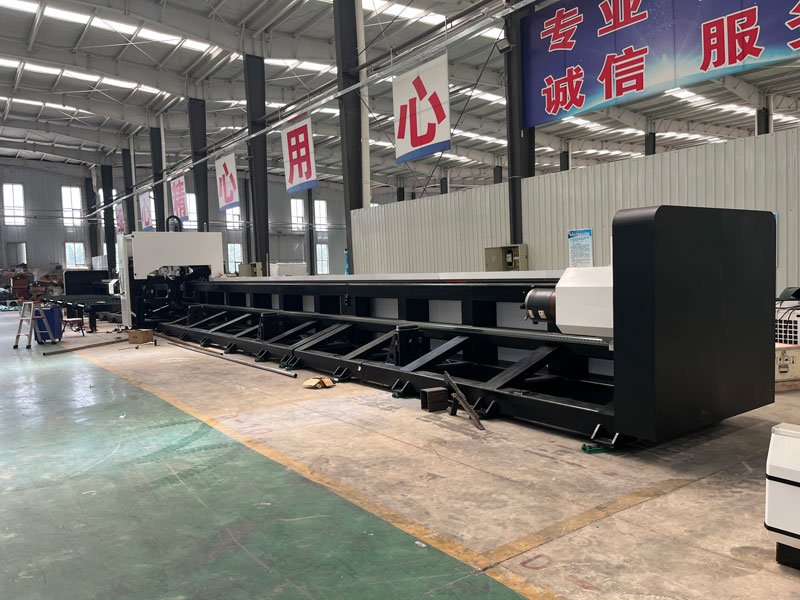

3000-12000W Heavy Duty Tube Laser Cutting Machine With Three / Four Chucks

3000W-12kW laser pipe cutting machine, labor saving, environmentally friendly and efficient

- Suitable for cutting large and heavy metal pipes

- Support 360° cutting at any angle and specified shape cutting

- Optional side-mounted loading device

- High load-bearing capacity for batch cutting

Introduction

DOWELL Super heavy duty laser pipe cutting machines are capable of processing large-diameter pipes, ranging from a few millimeters to hundreds of millimeters. It can not only handle traditional sizes of pipes but also cater to special large needs and meet the diverse needs of different industries for pipe sizes.

heavy duty tube laser cutting machine is suitable for cutting heavy metal tubes, including round tubes, square tubes, rectangular tubes, I-beams, U-shaped tubes and other tubes of different shapes.

It can cut heavy-duty pipes with diameters up to 500mm, lengths up to 12m, and weights up to 1600kg. The laser power is optional from 1000-12000W. Bevel cutting, side hanging and loading and unloading devices can be customized.

Tube laser video

heavy duty tube laser cutting machine

CNC loading and unloading automatic tube cutter machine

Heavy Duty Tube Laser Cutting Machine Technical Parameters

- Brand: Dowell Laser

- Power: 3000w-60kw

- Round tube cutting diameter: 20-500mm

- Square tube cutting diameter: 20-350mm

- Auxiliary gas: oxygen, nitrogen, air

- Maximum acceleration: 1.5G

- Customizable: 12m 24m

- Positioning accuracy: ±0.05mm

- Maximum chuck speed: 50r/min

- Additional functions: loading and unloading device, 3D 5-axis bevel cutting,

Features

High precision and high quality: Precise cutting is achieved and accurate cutting is carried out according to the predetermined contour, ensuring the accuracy and quality of the pipe. It is commonly used in the field of steel structures.

High efficiency: fast and stable production capacity. Complete cutting of multiple parts at one time, greatly improving production efficiency. It is suitable for enterprises that produce steel pipes in batches and improves overall production efficiency and manufacturing capabilities.

Wide adaptability: can handle pipes of various shapes and materials, including round, square, and special-shaped pipes. Pipes of different shapes and sizes have wide adaptability in the steel structure industry.

- Automated production line integration: The heavy-duty laser pipe cutting machine can be integrated with other equipment and automation systems to form a complete automated production line. Automated pipe processing, transportation, and storage can be achieved through the loading, discharging, and stacking of equipment used in conjunction with the pipe-cutting machine, improving the efficiency and accuracy of the entire production process.

- Large-scale production capabilities: Heavy-duty laser pipe cutting machines can handle high-volume pipe cutting tasks. For projects that require large-scale production, continuous cutting operations can be completed efficiently and production efficiency can be improved.

Heavy duty pipe laser cutting machine configuration

Heavy duty chuck

Can adapt to many different types of materials, such as carbon steel, stainless steel, aluminum alloy, etc. The scope of application can meet the needs of different projects and customers.

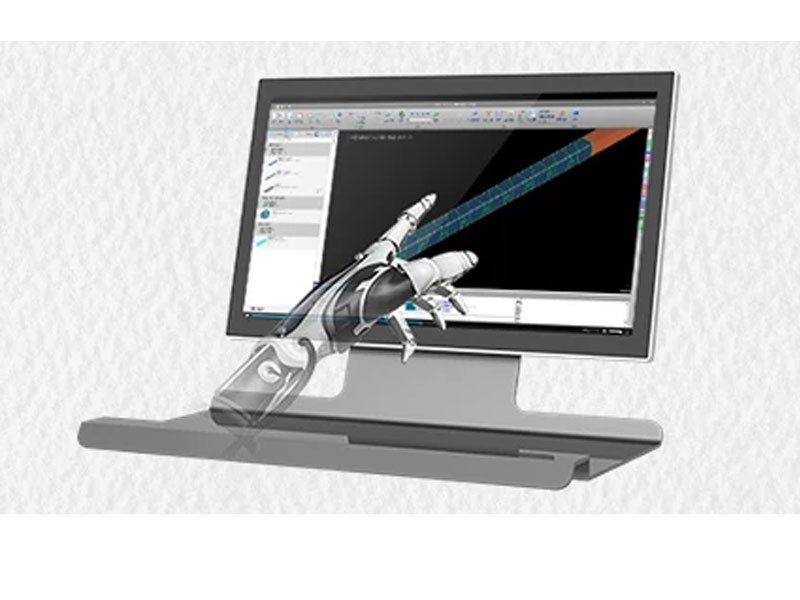

Simple and flexible pipe cutting system

The laser pipe cutting system is usually equipped with a drawing and mathematics interface, and the operation is simple and flexible. Through preset programs, cutting of various complex shapes can be realized to meet the personalized customization needs of different customers. Whether it is conventional or conventional geometries or special shaped pipes, they can be processed with ease.

Non-contact cutting technology

Non-contact cutting technology consumes additional cutting tools, reducing energy consumption and material waste. It does not produce losses or waste water, which is in line with the concept of green production in the manufacturing industry and contributes to sustainable development.

Using advanced laser technology

Achieve extremely high cutting precision. Whether it is plane cutting or three-dimensional cutting, the accuracy reaches the sub-millimeter level. High-precision cutting ensures the dimensional accuracy of pipes after processing and improves product quality and consistency.

laser tube cutting design

Customizable side mounting, three-dimensional five-axis bevel cutting function.Various accessories and functions can be added according to user needs, such as automatic loading, unloading system, tilt cutting, etc. The customized design makes the equipment more flexible and suitable for different application scenarios and process requirements, meeting customers’ needs for diverse work.

application

Equipment: sports and fitness equipment, clothing and props display racks, medical equipment;

Vehicle aviation: passenger car manufacturing, high-speed rail, and subway accessories, aerospace industry, etc.;

Furniture, kitchen, and bathroom: steel furniture, doors, windows, kitchen, and bathroom, etc.;

Technical support and training:

Heavy duty laser pipe cutting machines include training on equipment installation, operation guidance, maintenance and other aspects to ensure the normal operation and maximum utilization of the equipment.

Increase competitiveness:

Heavy duty tube laser cutting machines can enhance the competitiveness of industry enterprises. It can provide high-quality, high-efficiency, and flexible pipe processing, which can better meet customer needs, reduce production costs improve production efficiency, and gain an advantage in market competition.

Want to buy the most affordable heavy duty tube laser machine price

Contact us to get the latest metal pipe laser cutting equipment prices and recommend a suitable pipe cutting machine for you.

FAQ

Heavy-duty laser pipe cutting machine focuses on safety

Safety issues are particularly important in overloaded heavy-duty applications. Stronger structural and safety measures are taken into consideration This includes safety designs such as reinforced bases, protective devices, and emergency stop buttons to provide users with a safe and reliable working environment.

How much does a heavy duty laser pipe cutting machine cost?

The heavy-duty laser pipe cutting machine is more expensive than the ordinary economical pipe cutting machine because the bed and cutting system are relatively larger. The price is higher, generally around US$50,000-200,000.

Which metal laser pipe cutting machine is the best?

You need to choose the most suitable heavy duty laser pipe cutting machine brand based on your specific needs and budget. It is recommended that you carefully compare the product performance and after-sales services of different brands before choosing.

What are the benefits of customizing a heavy duty laser pipe cutting machine?

Improve equipment adaptability. For pipe cutting needs of different diameters, wall thicknesses and lengths, we can design and manufacture them according to customers’ specific requirements. This means that the customized heavy-duty laser pipe cutting machine can better adapt to pipes of different specifications, ensuring cutting quality and efficiency.

Can improve work efficiency. As custom equipment becomes more automated, the laser cutting process can be completed more quickly and accurately.

Improve cutting accuracy. Able to provide high-precision cutting solutions according to customer needs. Achieve higher cutting accuracy and reduce errors and scrap rates.

Metal laser pipe cutting machine after-sales services

15 years of laser equipment manufacturing experience, professional technical team, perfect after-sales services team technical support

How thick can laser cutting pipe be cut?

The thickness of laser cutting can reach about 10mm. The configurations of special laser cutting machines for pipes include imported and domestic ones. The required laser cutting machines can be configured according to different needs of customers.

With the development of technology, the higher the power, the thicker the thickness of the pipe cut.