A powerful tool for high-speed, high-precision, large-scale, high-quality production.

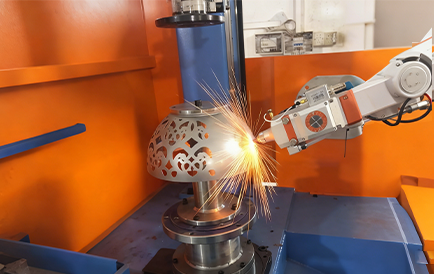

3 Dimensional 5 Axis

Fiber Laser Cutting Machine

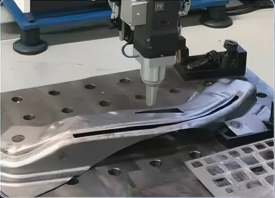

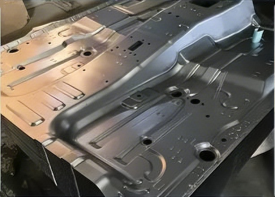

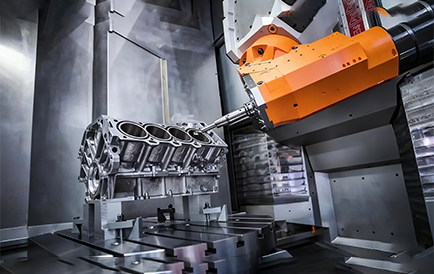

Precision cutting of lightweight aluminum alloy structural components for automobiles and engine turbine blades, enter the core supply chain of new energy vehicles

For the automotive industry

Seamless laser cutting of aerospace titanium alloy irregular-shaped parts and complex pipelines meets stringent military-grade production standards

For the aerospace industry

3D cutting of medical implants and precision instrument shells with a precision of 0.01mm meets the high requirements of the medical industry.

For medical equipment

Seamless Integration, Maximum Impact Diverse Needs, Comprehensive Coverage

Dowell Laser 3D 5Axis laser cutting equipment offers a complete range, covering everything from small-batch pilot production to mass production, meeting the diverse needs of intelligent automotive manufacturing.

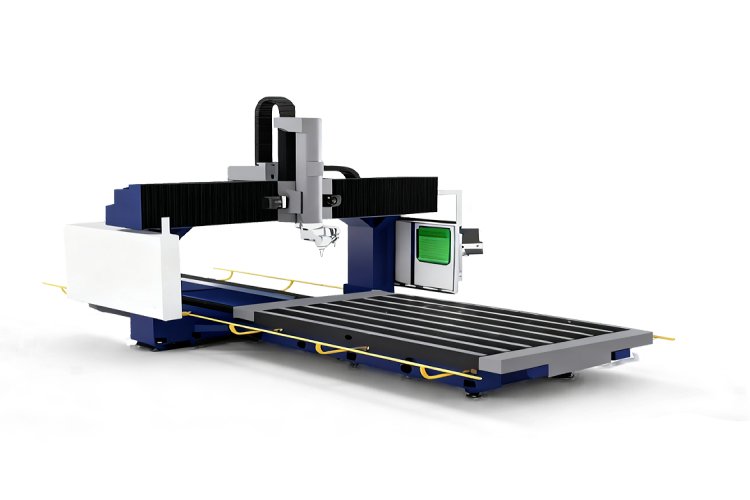

Seamlessly T Series - Excellent Value for Money

Large movable worktable with an open structure;Convenient workpiece and fixture hoisting and loading, offering excellent cost-effectiveness;

Suitable for automotive stamping die prototyping, small-batch processing of automotive parts, and small-batch processing of aluminum body parts.

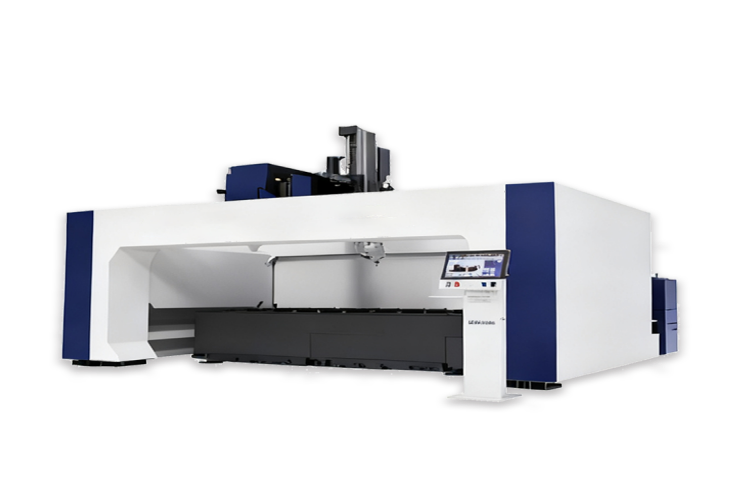

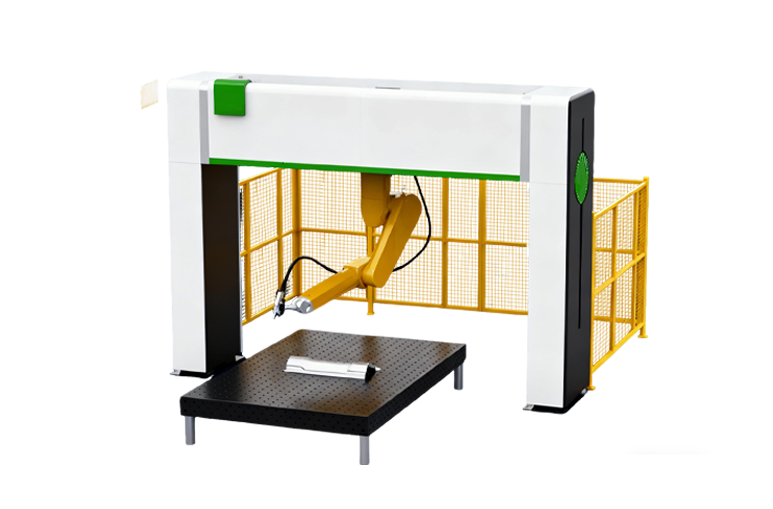

Easily S Series - Efficiency Expert

Semi-open structure, good openness

Simple structure, fast processing efficiency, single-axis speed up to 100m/min

Suitable for small-batch, multi-process production of molds, automotive parts, etc.

Effortlessly S Series - Lightweight Intelligent Manufacturing Expert

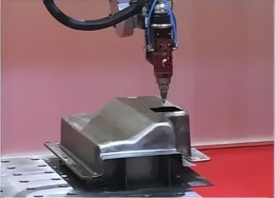

Powerful tool for automotive thermoforming 3D curved surface machining. Equipped with single or double-head cutting, single-axis speed up to 120m/min, offering high-speed, high-dynamic performance, and high-stability machining. Suitable for mass production of automotive A-pillars, B-pillars, single door rings, double door rings, as well as new energy battery trays and bottom shells. A leader in high-precision, high-efficiency production of high-strength steel 3D parts.

An ideal solution for cutting automotive thermoformed parts

It is a brand new equipment independently developed by Dowell Laser, combining years of experience in laser equipment manufacturing and accumulated application cases in the automotive industry.

Intelligent CNC System

This system has super computing power and a clear human-computer interaction interface, making the generation and debugging of cutting programs simple and convenient.

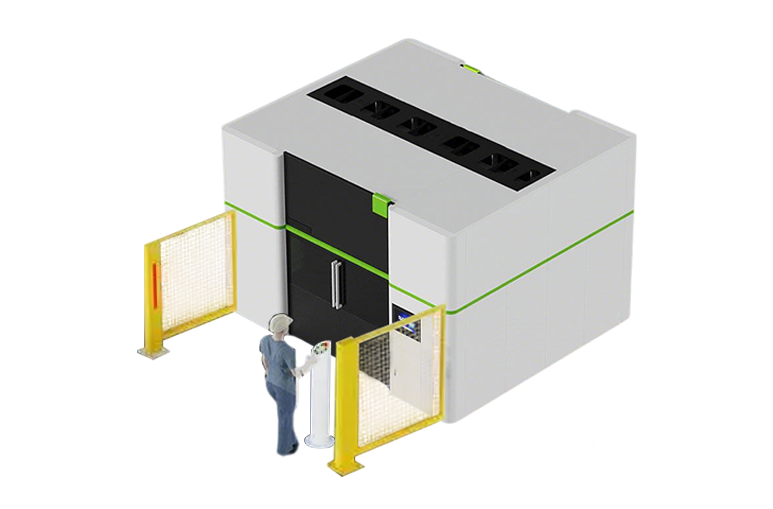

Green, Environmentally Friendly, Safe and Reliable

The design concept of green, friendly and safe includes the installation of comprehensive dust removal facilities inside to ensure a clean processing environment.

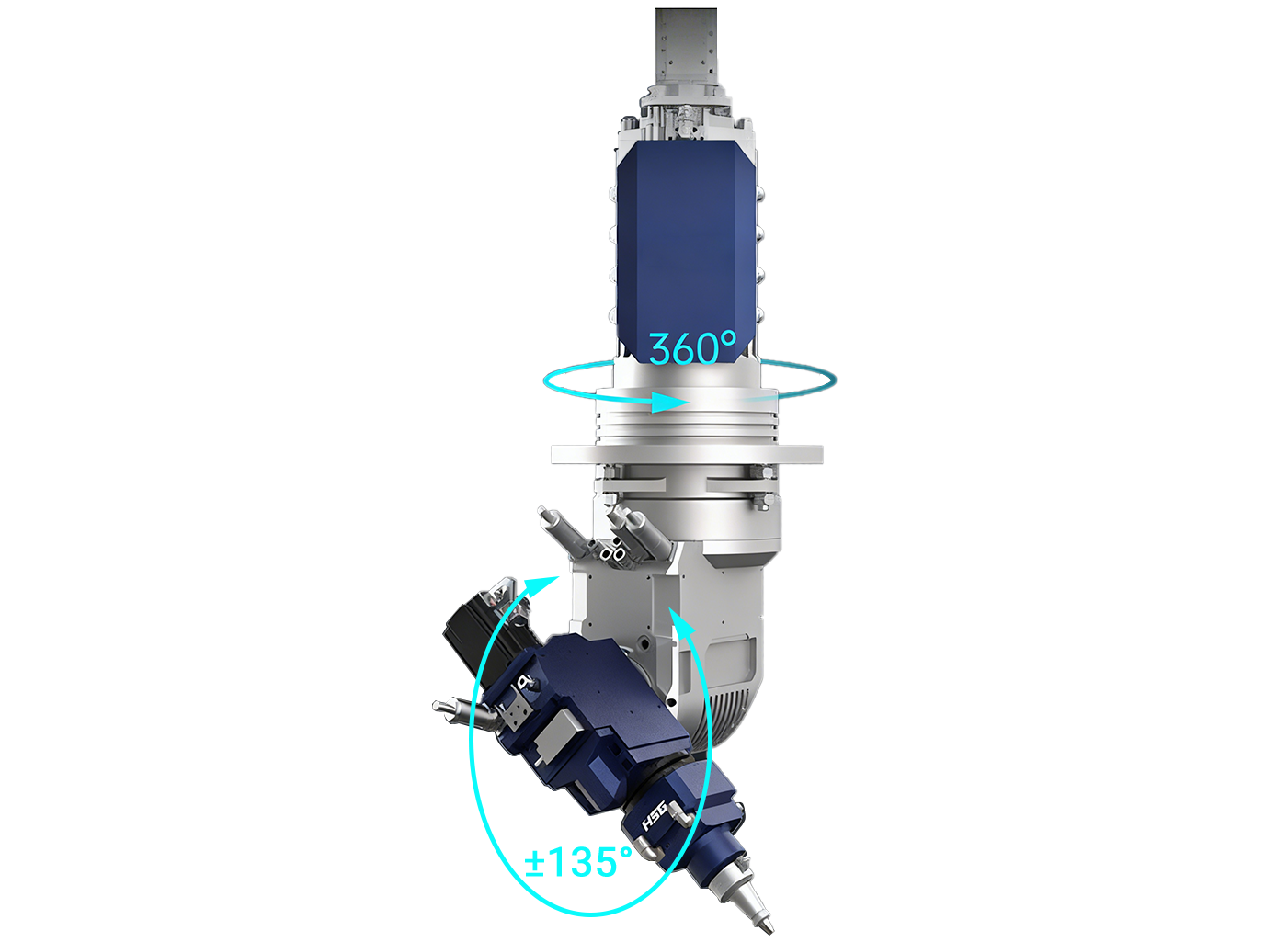

Equipped with a 5Axis Intelligent Cutting Head

-

Prevents damage to valuable components from collisions

-

Ensures processing of most 3D workpieces

-

Matches appropriate flow rate and process, guaranteeing cutting quality

-

Stable Optical Characteristics and High Reliability

3D 5Axis Laser Machining Technology

Ensure the cutting accuracy and quality of 3d complex surfaces

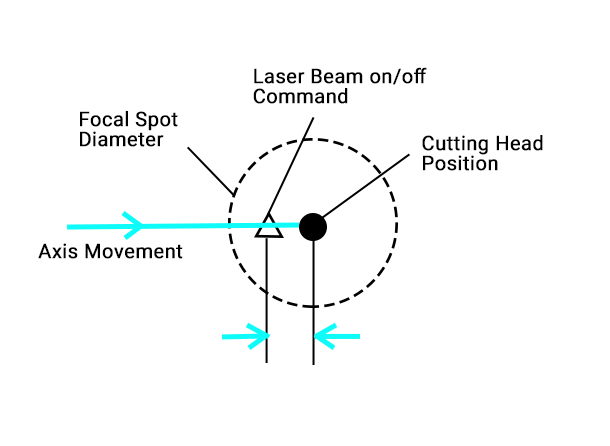

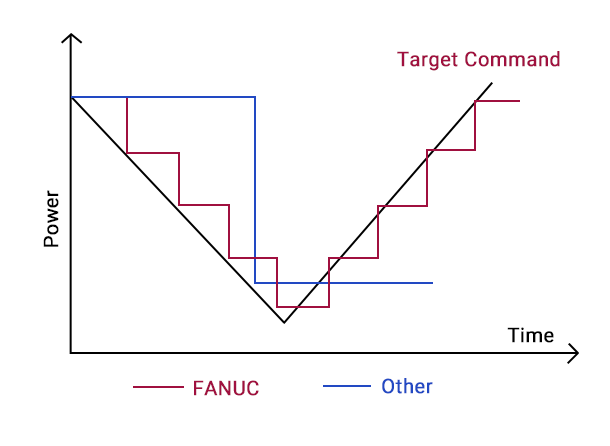

Flight Cutting Reduce the maximum positional deviation to within the range of focal spot diameter

Power Control Prevent Corner Burning

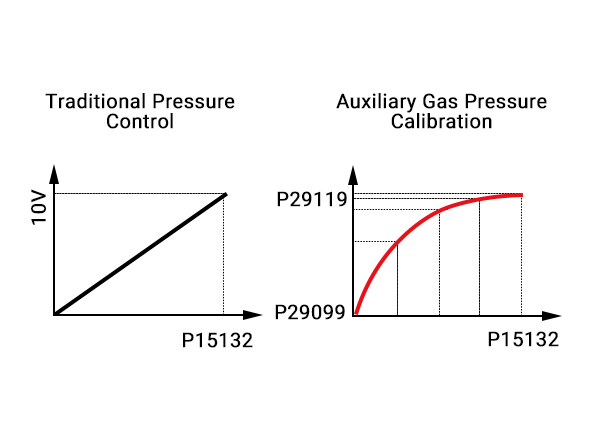

Auxiliary Gas Nonlinear Calibration Ensure the quality of the laser cutting section

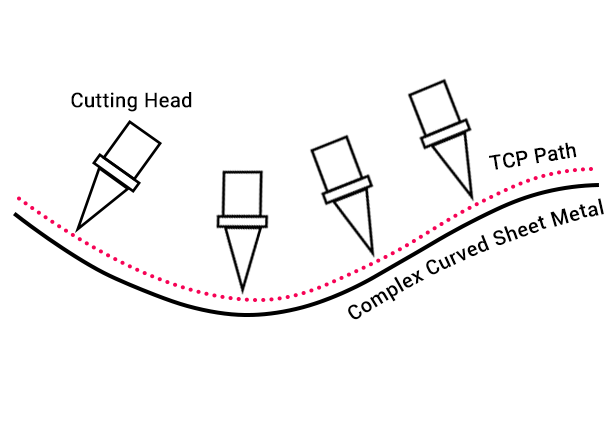

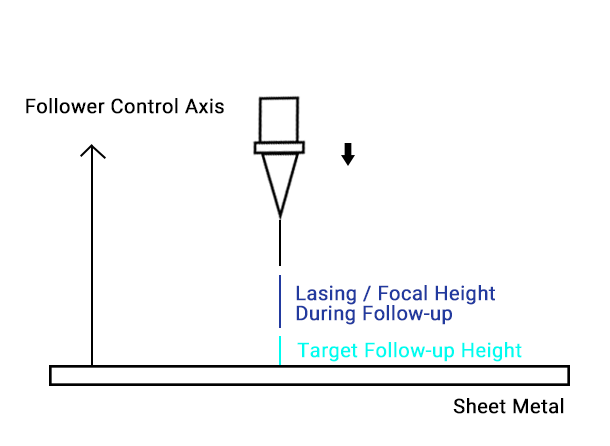

W-axis Follow-up Control Compensate for TCP point offset

Undetectable Piercing Improve the efficiency and quality of laser perforation

3D arc interpolation Simple programming for implementing spatial arcs

More Suggestions for Selection Priority Selection Guide: The Movable/interchangeable/Rotatable Workbench?

Choosing a 3D 5-axis laser cutting machine with movable/interchangeable platforms/rotatable workbenches essentially involves selecting “flexible production capacity”:

- If a company needs to balance multi specification workpieces, mass production, and space optimization, it can avoid the repeated investment of “one equipment corresponds to one type of workpiece”;

- Its “parallel job” feature can directly shorten the order delivery cycle, especially suitable for meeting the market order demand of “small batch, multi batch”;

- The convenience of operation reduces the dependence on skilled workers, while minimizing workpiece damage during handling, further reducing overall production costs.

| Workbench | Core Advantages | Applicable Scenarios | Selection Guide |

|---|---|---|---|

| Fixed workbench | Strong stability, suitable for ultra precision small parts | Aerospace micro components, high-precision molds | Flexible adaptation to multiple specifications of workpieces, higher space utilization efficiency |

| Rotary worktable | Suitable for processing circular/symmetrical surfaces | Rotating parts such as pipelines and wheel hubs | Supports ultra long/ultra wide workpieces, enabling parallel operations |

| Moving workbench | Flexible adaptation, efficient collaboration, space friendly | Multiple batches of small and medium-sized parts, large and medium-sized irregular parts, compact workshop | Balancing "complex processing+flexible production+space saving", with no shortcomings in adaptability |

Fixed Workbench (Standard Configuration)

The fixed worktable can carry large workpieces, and the stationary worktable avoids vibration during processing, ensuring cutting accuracy. The stable performance of the fixed workbench under long stroke conditions meets the cutting needs of industries such as shipbuilding for large-sized workpieces.

Rotary workbench (Optional)

The rotating worktable effectively reduces the number of clamping times and errors, efficiently optimizes the cutting process, achieves continuous operation, and shortens processing time; Expand the processing range, handle large and irregularly shaped workpieces, and improve production efficiency.

Moving Workbench (Optional)

The movable workbench can be directly moved to the operator’s side without bending over or using auxiliary tools to transport workpieces: It can process small precision parts (such as medical device components and mobile phone frames), as well as adapt to medium to large shaped workpieces (such as car bumper molds and robotic arm joints), without the need to replace dedicated workbenches;

Selection Manual: Which size device is more suitable?

From 2D to 3D, from simple to complex, it handles both mass production and customized processing, One machine = a multi-dimensional processing workshop!

| Project | DW-3015 | DW-4020 | DW-4025 | DW-6020 |

|---|---|---|---|---|

| X/Y/Z axis travel range | 3000/1500/680mm | 4000/2000/680mm | 4000/2500/680mm | 6000/2000/680mm |

| A-axis travel | ±135° | ±135° | ±135° | ±135° |

| C-axis travel | ±nx360° | ±nx360° | ±nx360° | ±nx360° |

| Maximum speed of X/Y/Z axis | 60m/min | 100m/min | 100m/min | 80m/min |

| Maximum acceleration of A/C axis | 3600°/s² | 3600°/s² | 3600°/s² | 3600°/s² |

| Maximum speed of A/C axis | 540/s² | 540/s² | 540/s² | 540/s² |

| Maximum acceleration of X/Y/Z axis | 0.5G | 1G | 1G | 0.8G |

| Positioning accuracy of X/Y/Z axis | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

| Repeat positioning accuracy of X/Y/Z axis | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| Positioning accuracy of A/C axis | 0.03⁰ | 0.03⁰ | 0.03⁰ | 0.03⁰ |

| Repeat positioning accuracy of A/C axis | 0.01° | 0.01° | 0.01° | 0.01° |

| Floating axis range | ±12.5mm | ±12.5mm | ±12.5mm | ±12.5mm |

| CNC system | SIEMENS 840D SL | SIEMENS 840D SL | SIEMENS 840D SL | SIEMENS 840D SL |

| Workbench | Fixed/Rotating/Moving | Fixed/Rotating/Moving | Fixed/Rotating/Moving | Fixed/Moving |

| Configurable laser device | 1000W~6000W | 1000W~6000W | 1000W~6000W | 1000W~6000W |

Breakthrough the limit of spatial cutting!

3D 5 Axis Laser Cutting Application Areas

Automobile Manufacturing

Construction Machinery

Medical Machinery

Metal Mold

Rail Transit

Aircraft & Aerospace Equipment

Shipbuilding Manufacturer

Curtain Wall Building Ceiling

Wind Power Communication Equipment

Door Industry Elevator Lifter

Domestic Appliances

Machine Tool Components

Alternative Punching Die

Focusing on core areas of high-end manufacturing.

Empowering High-Precision Machining

Deeply adapted to high-precision processing fields such as automotive manufacturing, aerospace, new energy, mold making, and medical devices!

Five-axis simultaneous machining precisely overcomes the challenges of cutting complex curved surfaces, irregular contours, and three-dimensional parts, achieving high-precision, burr-free, one-time forming. This empowers the high-end manufacturing sector with upgraded processing efficiency and quality control, building core competitiveness for high-value-added production!

|

Application Areas

|

Typical Process Types

|

Necessity

|

Examples of Representative Parts

|

Technical Highlights

|

|---|---|---|---|---|

|

Construction Machinery (Excavators/Loaders)

|

High-strength steel hot stamping + cold stamping hybrid process

|

The boom, arm, and chassis structural components have thicknesses ranging from 20 to 50 mm, requiring complex bevel cutting to ensure welding strength. Traditional cutting methods are inefficient and lack sufficient precision.

|

Core load-bearing components such as the boom, arm, and chassis structural parts of 30-100 ton excavators from Komatsu, Hitachi, Kobelco, and Sany.

|

Construction machinery components are not only thick, but often require multi-angle bevel cutting to ensure welding strength. 3D 5 axis laser cutting can complete bevel processing at various angles in a single pass, resulting in stable cutting quality, significantly reducing subsequent welding defects, and improving the overall structural strength and safety of the machine.

|

|

Luxury/Supercar Carbon Fiber Body

|

Carbon fiber RTM (Resin Transfer Molding) and prepreg autoclave molding

|

After curing, carbon fiber parts become as hard as stone. Traditional processing methods easily cause delamination and burrs, so only 5 axis laser (or waterjet) cutting can be used to cut the outer contour and mounting holes.

|

The monocoque chassis and aerodynamic kits of the Lamborghini Aventador, Bugatti Chiron, and Rimac C_Two.

|

Carbon fiber composite materials possess high strength and lightweight characteristics, but they are extremely difficult to process. 3D 5 axis laser cutting enables non-contact processing, avoiding delamination and damage to the carbon fibers, resulting in excellent cutting edge quality and eliminating the need for subsequent grinding. This significantly improves production efficiency and product quality.

|

|

Naval Architecture and Ocean Engineering

|

Post-weld finishing of thick (30mm~100mm) high-strength steel multi-layer welds.

|

For extra-large, thick plates, welding deformation necessitates 5 axis laser and plasma composite cutting to ensure dimensional accuracy and bevel quality. Traditional cutting methods are inefficient and produce inconsistent results.

|

Key maritime components such as support structures for spherical tanks on LNG carriers, FPSO module edges, and structural components for warship decks.

|

Ships and offshore engineering equipment often need to operate for extended periods in harsh environments, requiring extremely high structural strength and reliability. 3D 5 axis laser cutting enables high-precision cutting of thick plates and complex bevel processing, ensuring welding quality while significantly improving processing efficiency and shortening the construction cycle of large-scale maritime equipment.

|

|

Military Armored Vehicles

|

Processing of homogeneous armor steel, aluminum armor, and composite armor.

|

Multi-layer welding requires laser cutting with a large bevel angle of 45° to 60°, and the cutting process must avoid the pre-drilled holes for the explosive reactive armor. This demands extremely high processing precision and safety standards.

|

Armor components such as the side skirts of the 99A main battle tank, and the turret base of the American Stryker and German Puma infantry fighting vehicles.

|

Armored vehicle components are not only thick, but their processing accuracy directly affects their protective performance. 3D 5 axis laser cutting can achieve precise cutting at complex angles, ensuring seamless joining of armor plates while avoiding any impact on material properties during processing, thus guaranteeing the protective capabilities of the armor.

|

|

Medical Devices (Implant-grade Titanium Alloy)

|

Additive manufacturing (3D printing) + hot siostatic pressing

|

After 3D printing titanium alloy acetabular cups and spinal cages, five-axis laser cutting is necessary to remove supports and refine the contours. Traditional machining methods can easily cause stress concentration and surface damage.

|

Implantable medical devices such as artificial hip joints, spinal fusion devices, and cranial repair plates.

|

Implantable medical devices require extremely high precision in processing and surface quality, which directly impacts patient safety and treatment effectiveness. 3D 5 axis laser cutting can achieve micron-level precision, resulting in smooth cutting surfaces and avoiding stress concentration and material damage that may occur with traditional processing methods. This improves the biocompatibility and lifespan of the implants.

|

|

Robots and Fixtures/Jigs for Automated Production Lines

|

Machining of large aluminum alloy/steel frame structural components

|

Complex spatial angles, hole positions, and mating surfaces are all completed in a single pass using 5 axis laser processing; traditional machining methods require multiple setups, making it difficult to guarantee accuracy.

|

High-precision tooling such as welding fixtures for automotive body-in-white, and base and arm connecting parts for KUKA/Fanuc robots.

|

Automated production line fixtures and robot components often have complex spatial angles and high precision requirements, which are difficult to meet with traditional processing methods. 3D 5 axis laser cutting allows for complete processing in a single setup, ensuring precise fitting between components, improving the accuracy and stability of the automated production line, and shortening the tooling development cycle.

|

Three Unchanging Laws of 3D 5 Axis Laser Technology in 2026

Through in-depth analysis of the core application areas mentioned above, Dowell Laser can summarize three "iron laws" of 3D 5 axis laser cutting technology in manufacturing in 2025. These laws reveal why this technology is indispensable in modern industry:

→ 100% require five-axis laser trimming. Hot stamping technology can significantly increase the strength of steel plates (up to 1800-2000 MPa), but the formed parts have large excess material and complex deformation. Traditional trimming dies are not only expensive (a set of large hot stamping dies can cost millions of yuan), but also difficult to handle complex 3D curved surfaces and special requirements such as 45° bevel cuts.

3D 5 axis laser cutting perfectly solves this problem. It can adaptively cut according to the actual shape of the part, easily handling various complex contours and angles, with tolerance control within ±0.3mm. More importantly, laser cutting does not require molds, allowing for quick response to design changes and shortening the new product development cycle by more than 30%.

→ Only 5 axis laser (or laser-plasma composite) is suitable. For high-strength steel or aluminum alloy parts with a thickness exceeding 15mm, traditional cutting methods face huge challenges: plasma cutting has low accuracy (±1mm or more), waterjet cutting is inefficient and costly, and mechanical processing is prone to stress deformation.

3D 5 axis laser cutting (or laser-plasma composite cutting) technology can achieve high-quality thick plate cutting. Not only can it achieve an accuracy of ±0.5mm, but it can also directly cut welding bevels at various angles (30°~60°), eliminating subsequent grinding processes. Taking a 20mm thick engineering machinery structural part as an example, the five-axis laser cutting speed can reach 1.5m/min, which is 5-8 times faster than traditional mechanical processing, and the cutting surface roughness can reach below Ra12.5μm, perfectly meeting welding requirements.

Only 5 axis laser or waterjet cutting can process these advanced materials. Carbon fiber composites, titanium alloys, and 3D printed metal parts possess excellent mechanical properties, but they are extremely difficult to machine. Traditional machining methods can lead to problems such as carbon fiber delamination, titanium alloy work hardening, and internal stress release in 3D printed parts.

3D 5 axis laser cutting, as a non-contact processing method, perfectly solves these problems: the laser energy is highly concentrated, resulting in a small heat-affected zone (usually less than 0.1mm), and no mechanical stress is generated; the cutting accuracy can reach ±0.05mm, meeting the stringent requirements of aerospace and medical devices; for composite materials such as carbon fiber, laser cutting also avoids fiber pull-out and delamination caused by traditional processing, significantly improving product quality and reliability.

Frequently Asked Question

DW-F3D 996FC 3D Five Axis Laser Cutting Machine: cut and shape aviation grade irregular parts and automotive curved parts in one time, increasing material utilization by 15%, saving 200,000 consumables costs annually, and directly shortening delivery cycles by 30%.

The application range of 3D laser cutting machine is very wide, mainly used in small batch and prototype processing of large parts processing, automotive, aerospace, locomotive and vehicle, engineering machinery, agricultural machinery, turbine assembly, white goods and other industries, as well as batch processing of metal thermoformed parts.

Taking the automotive industry as an example, the development of cover parts is one of the most important aspects of automotive development, which generally requires the use of molds to complete processes such as cutting, rolling, trimming, and punching. Each process requires the manufacture of corresponding molds for stamping, and the development and debugging of these molds require a lot of time, which often restricts the development speed of the entire car. After the completion of cutting, rolling, and shaping of the covering parts, the 3D laser cutting machine can complete processes such as edge cutting and punching. The heat affected zone of 3D laser cutting is small, the incision is smooth and free of burrs, and it can be used directly without further processing of the incision. This enables the production of complete automotive panels before the completion of the entire set of molds, accelerating the development cycle of new automotive products.

Each hot forming press requires several 3D laser cutting machines, and with the increasing popularity of hot stamping technology, the demand for efficient 3D laser cutting machines continues to increase. In fact, there are many industries that require the use of 3D laser cutting machines, but the price threshold has deterred many potential customers, which is also an important reason why Dowell Laser has launched a high-quality DW-F3D 996FC laser cutting machine.

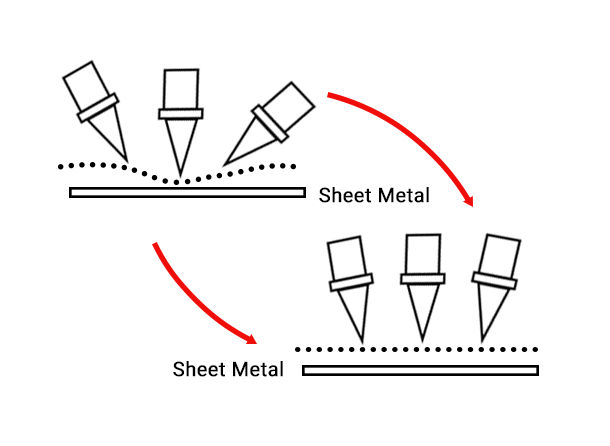

2D laser cutting machine cuts sheet metal, 3D pipe cutting machine cuts pipes and profiles, and the shapes of the processed objects are relatively regular. 3D laser faces much more complex processing objects. Taking car coverings as an example, the shape of the parts is a large-sized three-dimensional structural component, mostly complex curved surfaces, and there are also a large number of fixtures on the parts, which means that the cutting trajectory is complex, the difficulty of precise positioning is high, and the program calculation is large,

Because the cutting head needs to adjust its angle at any time to ensure vertical cutting with the cutting surface, while also avoiding collisions with fixtures and parts.

In addition, automotive processing is a large-scale production method that requires high efficiency. After stamping, the parts often have springback deformation and errors in the CAD numerical model of the product. Different batches of parts also have processing errors, but the accuracy and consistency of automotive parts processing are far greater than in most industries. During the cutting process, it is important to pay attention to whether the cutting is efficient and stable, whether there is overburning or slag hanging, whether the cutting surface is smooth enough, and whether the cutting width and taper meet the standards. There are extremely high requirements for the software and hardware of the laser cutting machine.

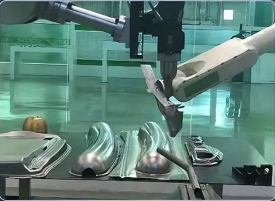

There are two main types of 3D laser cutting equipment: 3D laser cutting machine tools and laser cutting robots. 3D laser cutting machine tools have good rigidity, fast processing speed, and high processing accuracy, but the operating space of the laser cutting head is limited to a certain extent, and the ability to approach the processing area is relatively poor; Laser cutting robots have high flexibility, and the laser head can approach the cutting area, but they are not as fast and accurate as 3D laser cutting machines in terms of processing speed and precision. So the global automotive industry is still dominated by 3D laser cutting machines.

Regarding the DW-F3D 996FC 3D laser cutting machine, in simple terms, there has been a significant improvement in processing accuracy, flexibility, and efficiency, with a wider range of applications. Taking the cutting of thermoformed door rings as an example, our cutting time for a single piece is 102 seconds, which is equivalent to 3600 seconds per hour. We can process approximately 35.3 pieces per hour and over 800 pieces in 24 hours, which is about 30% faster than machines of the same configuration in the same industry.

The machine structure and core components of a laser cutting machine are crucial for the quality of cutting. What are the characteristics of DW-F3D 996FC worth introducing?

The DW-F3D 996FC integral welded steel gantry structure ensures excellent rigidity and is easy to install. The workbench is designed for easy access. The X and Y axes are driven by linear motors and linear drives, without gearboxes, transmission belts, racks, and ball screws, reducing wear and maintenance. The Z axis is made of cast aluminum material and driven by a brushless motor, with high hardness and light weight. The optical path shuttles through the hollow and sealed Z axis.

In addition, the laser processing head is also a measuring head with high accuracy, generally within the range of 0.1mm. It provides standard measurement reference blocks, automatic program repositioning, and point position measurement function to automatically measure the geometric position of each axis of the processing head and the alignment position of the laser beam. Automatically verify the geometric position of each axis of the cutting head without the need for operator intervention, automatically calculate the zero position and offset of each axis of the cutting head, and display the measured values clearly on the CNC screen, avoiding errors that may be caused by manual misoperation.

In the process of mass production, it is possible to accurately detect whether the cutting pieces have completely separated and fallen off from the parts, avoiding any impact on subsequent processes. The material drop detection function can check whether the pieces cut by various closed contours such as holes and grooves have fallen off through capacitive sensors.

Unlike optical detection, sensor detection is not affected by surrounding fixtures or materials, with a typical detection time of about 200ms and a minimum hole diameter of about 4mm.

Dowell Laser offers professional offline programming software, providing a wide range of 3D model data interfaces that can import 3D drawings in different formats without the need for format conversion; Advanced computer-aided manufacturing functions ensure the shortest machining cycle by optimizing the machining program; Integrated post processor for all 3D laser devices; Capable of designing parts and fixtures; Capable of simulating processing programs.

Dowell laser cutting machine is equipped with a portable self-learning programming manual control box, which conforms to ergonomics and has a more intuitive and vivid interface display screen, as well as a joystick with speed control function; When connected and used, a single unit can be used for the installation of multiple machine tools. A graphic editing software is also installed on the equipment console, which can convert G-code processing programs into graphic displays, making the processing path clear at a glance and facilitating program modification; Simulate the running of the processing program, and after modifying the program, the new program can be saved online.

The launch of the DW-F3D 996FC three-dimensional five axis laser cutting machine demonstrates Dowell Laser’s hardcore strength in the field of high-end intelligent cutting equipment. There will be huge development space for future 3D laser cutting machines, and Dowell Laser will provide strong support for the transformation of China’s laser cutting field from ‘Made in China’ to ‘Intelligent Manufacturing in China’ with practical actions, empowering the automotive manufacturing industry.