All-in-one Processing: Water Guided Laser Cutting, Drilling, Sloting, and Carving.

Providing the most valuable solutions for advanced manufacturing

No Need Focus Adjustment

Long working distance -> No need for focus adjustment during processing

Zero Grinding of Cross-section

No heat-affected zone / No burrs / High-quality cut surface

Micron-level Precision Cutting

Fine cutting ratio up to 400:1 for kerfs greater than 0.04mm

Deep Holes Forming

Micro-hole machining depth-to-diameter ratio up to 20:1 for diameters greater than 0.3mm

Multi-dimensional Processing

Tilting and drilling capabilities / Multi-dimensional arbitrary cutting

Simple Operator

Tool-free, low material consumption / Easy to learn and use

Water guided laser processing: a revolutionary solution for ultra precision manufacturing

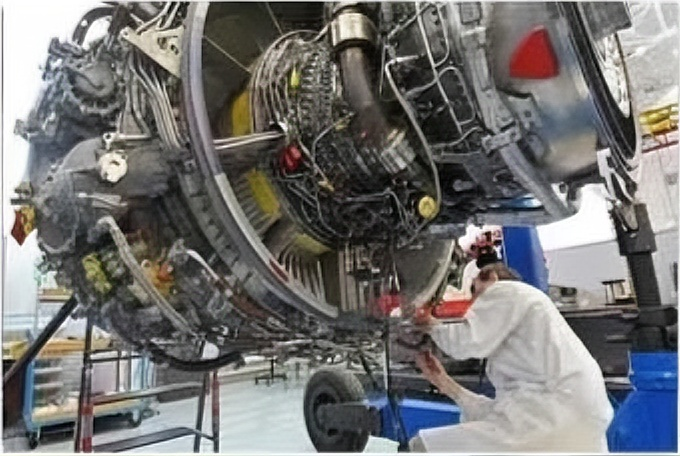

In the field of ultra-precision manufacturing, traditional processing technologies are facing a dual challenge of “precision bottlenecks” and “material limitations”—laser cutting easily causes thermal damage, mechanical processing easily induces stress deformation, and waterjet cutting struggles to achieve sub-micron precision. Water-guided laser processing technology combines the cooling characteristics of high-pressure water jets with the high energy density advantages of lasers, achieving “zero thermal impact, stress-free, and ultra-precision” processing results, making it a revolutionary solution for high-end manufacturing fields such as 3C electronics, optical devices, aerospace, and medical devices.

-

Self-developed Core Software

Self-developed CNC system, mastering the "brain" of the equipment from the ground up.

-

Self-developed Core Hardware

Adhering to forward engineering and controlling independent intellectual property rights.

-

Benchmarking Against International Standards

Benchmarking against leading international technologies to further optimize specific indicators.

-

Flexible Expansion Capabilities

Based on underlying technology, expanding to five-axis and peripheral automation.

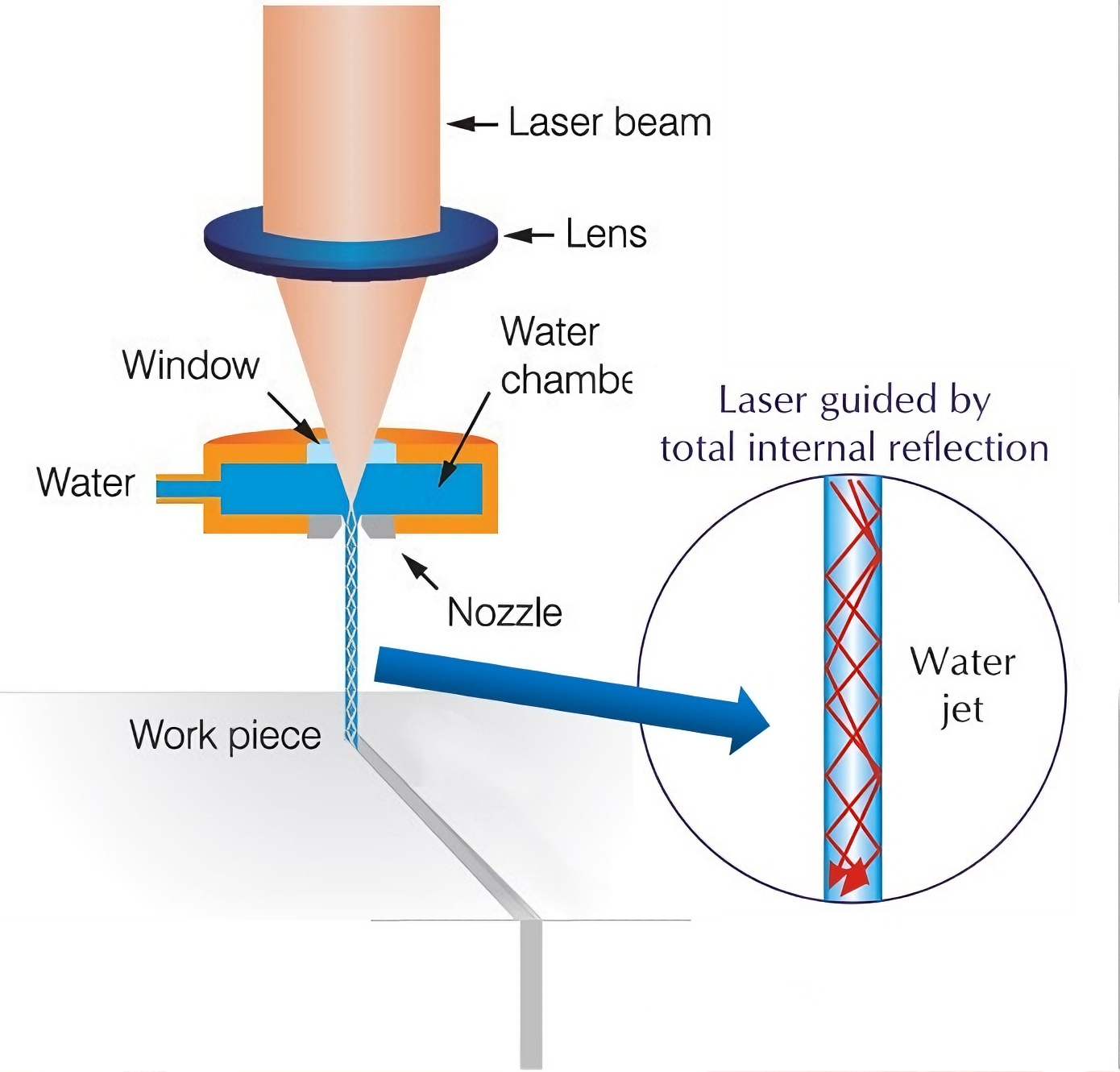

The Working Principle of Water-Guided Laser Processing Technology

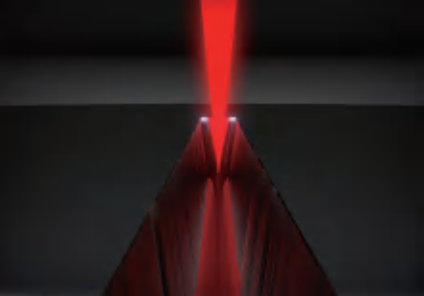

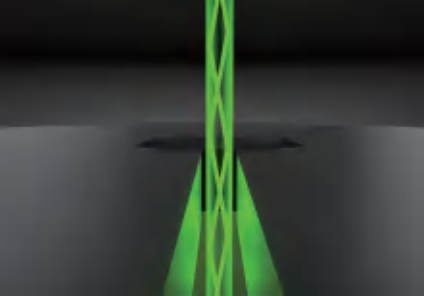

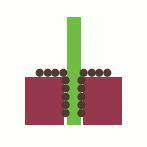

Water-guided laser processing technology is a hybrid processing method that combines a laser with a “hair-thin” water jet. The water jet precisely guides the laser beam through total internal reflection, similar to how traditional optical fibers work. The water jet continuously cools the cutting area and effectively removes debris. As a “clean, controlled, and cold laser technology,” water-guided laser processing technology addresses significant problems associated with dry laser processing, such as thermal damage, contamination, deformation, debris deposition, oxidation, microcracks, taper, and low precision.

The basic concept of water-guided laser technology is to use water as a light-guiding medium to transmit the laser. Traditional optical fibers are usually made of glass or plastic, and light is transmitted internally through total internal reflection. The water-guided laser system utilizes the special optical properties of water, particularly its high transparency and low loss characteristics for specific laser wavelengths. When light propagates in a medium, if the angle of incidence is greater than a certain critical angle when light enters a medium with a lower refractive index from a medium with a higher refractive index, total internal reflection will occur at the interface. Traditional optical fibers utilize this principle, using the difference in refractive index between the inner and outer layers of the glass fiber to cause light to reflect multiple times within the fiber. Water-guided lasers utilize the difference in refractive index between water (approximately 1.33) and the surrounding air (approximately 1.0) to achieve total internal reflection. In this way, the laser can be transmitted along a specific path in the water, similar to light propagation in an optical fiber.

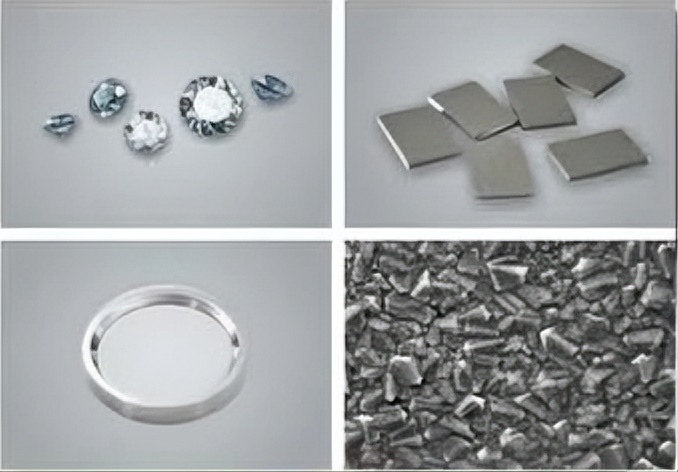

Application Areas & Industry Applications Ultra-precise, Non-destructive, and Widely Compatible

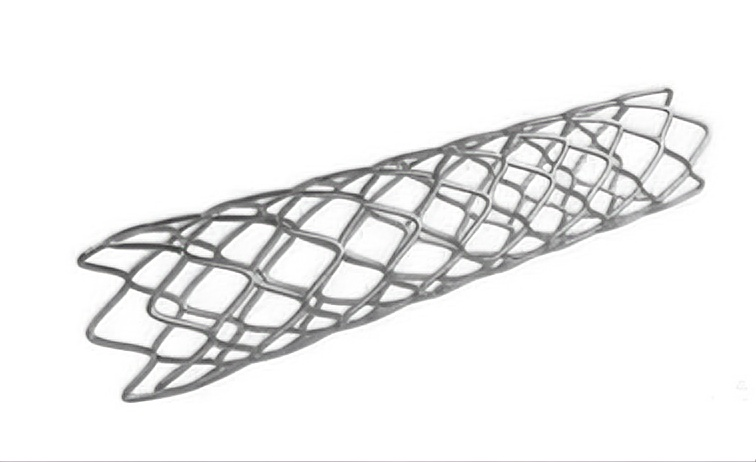

A leading cardiovascular stent manufacturer: Previously, using traditional laser processing, the stent surface roughness was Ra=2.8μm, resulting in a high rate of platelet adhesion and hindering regulatory certification; after switching to water jet guided laser technology, the Ra value decreased to 0.9μm, enabling them to obtain EU CE certification and resulting in a 50% increase in orders.

Waterjet Guided Laser VS Conventional Laser

While traditional laser processing has achieved automated cutting, it still faces significant limitations in high-end precision manufacturing, such as thermal damage, limited accuracy, and narrow material compatibility. Water-guided laser technology, however, leverages an innovative coupling of "laser + high-pressure water jet," fundamentally revolutionizing traditional processing logic and demonstrating overwhelming advantages in ultra-precision, high-value manufacturing scenarios.

- Ensuring the performance of precision parts

- Improving yield rate and reducing processing steps

- Breaking through process limitations

- Expanding business boundaries

- Long-term cost reduction and efficiency improvement

- Handling complex processes with a single machine

- Enhancing mass production competitiveness

Main Highlights and Processing Capabilities

The seamless integration of water jet and laser technology is revolutionizing traditional laser processing methods, exploring and discovering the future of precision machining for industrial ceramics. This innovative approach is unparalleled in accuracy and versatility, surpassing traditional techniques and offering higher processing efficiency and superior results.

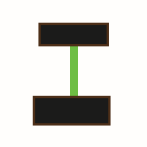

No Taper

Using a cylindrical laser beam, material waste is minimized, resulting in narrow kerfs and no taper on the sidewalls, improving efficiency and cost-effectiveness.

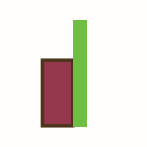

High Aspect Ratio

This water-guided laser technology can drill holes with aspect ratios up to 1:20 (diameter to depth) with no taper on the sidewalls.

No Tool Wear

Dowell Laser's non-contact processing technology ensures low operating costs and high processing efficiency.

High Precision, High-Quality Edges, Low Roughness, No Microcracks

The Dowell Laser water-guided laser processing system is an ultra-precise tool that maintains perfect, crack-free edges on the workpiece during processing, ensuring your final product meets the highest quality standards.

Applicable to a variety of industrial precision ceramics

Dowell Laser's water-guided laser technology can process oxides such as alumina and zirconia, non-oxides such as SiC, B4C, CBN, AlN, SiN, and GaN, as well as composite materials for various applications.

No heat-affected zone, no structural deformation.

Due to the cooling effect of the laser waterjet, there is no heat influence during the machining process, eliminating the risk of altering the material properties during processing.

Technological Advantages: Traditional Laser VS Water Jet Guide Laser

Water microjet laser technology is by no means a mere "upgrade" of traditional lasers, but rather a "revolutionary technology" for ultra-precision machining. It fundamentally solves the problems of thermal damage and processing limitations associated with traditional lasers, helping you upgrade from simply "being able to process" to "being able to process well and process high-end materials," giving you a significant competitive advantage in the industry!

Conventional Laser Processing

Comparison Chart 1

Comparison Chart 2

Microjet Laser Processing

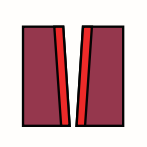

Precise focus adjustment required

No focusing required, enabling 3D cutting on non-planar surfaces to depths of several centimeters.

Conical laser beams leave non-parallel cut walls.

Cylindrical laser beam with parallel edges

Limitations on cutting aspect ratio

High aspect ratio, very small kerf width (>20 µm), minimal material loss, capable of deep cutting

Larger remelted layer and heat-affected zone

Water cooling process prevents thermal damage and material changes, maintaining high fracture strength

Processing debris particle deposition

Thin water film eliminates particle deposition and contamination, no surface protection layer required

Low material removal efficiency, prone to burrs

High kinetic energy of the water jet expels molten material, preventing burr formation

Limited to conductive materials

Wide range of application fields

Slow ablation process, long preparation time

Fast processing speed

High electrical discharge wire consumption

Low operating costs (no tool wear, low water consumption, and low scrap rate)

Comparison of Typical Cutting and Drilling Processing Techniques and Characteristics

In contrast, water microjet laser processing technology combines the advantages of both water and laser, overcoming many shortcomings of traditional processing methods.

Characteristic

Plasma Arc

Oxy Fuel Cutting

Water Jet Cutting

Dry Laser

Electrical Discharge Machining

Laser Waterjet

Energy Type

Thermal

Thermal

Mechanical

Thermal

Electrothermal

Thermal

Machining Accuracy

±0.3...3

±0.5...2

±0.02...1

±0.02...1

±0.001...0.1

±0.001...0.01

Minimum Inner Redius

0.5...3

0.6...3

0.2...0.7

0.1...0.2

0.013...0.2

0.015...0.05

Minimum Hole Diameter

5.0

10.0

0.5

0.5

0.2

0.2

Cutting Width

1...6

1.2...6

0.3...1.5

0.2...0.4

0.025...0.4

0.03...0.1

Processing Thickness

1...200

3...600

0.01...300

0.05...30

0.01...400

0.005...25

Multilayer Cutting

No Possible

No Possible

Possible

No Possible

Possible

Possible

Roughness Ra(μm)

1.6...200

3...600

0.01...300

0.05...30

0.01...400

0.005...25

Taper

0.1..3

0.1...2

0.02..0.5

0.02..0.5

0.001

0.001...0.01

Heat Affected Zone

0.25...8

0.5...10

0

0.1...2

0.02

0.002...0.01

Burr

0.2...2

0.3...4

0...1

0...1

0

0

Appearance

Melted/Oxidized

Oxidized/Black

Sandblasted/Matt

Oxidized/Metallic Blank

Matt/Shiny

Shiny

Aluminum Thickness

50

-

150

20

400

>30

Carbon Steel Thickness

200

600

100

30

400

>30

CrNi Alloy Thickness

200

-

100

30

400

>30

Nonferrous Thickness

10

-

100

30

400

>30

Synthetics Thickness

-

-

150

25

-

>30

Stone Thickness

-

-

150

-

-

>30

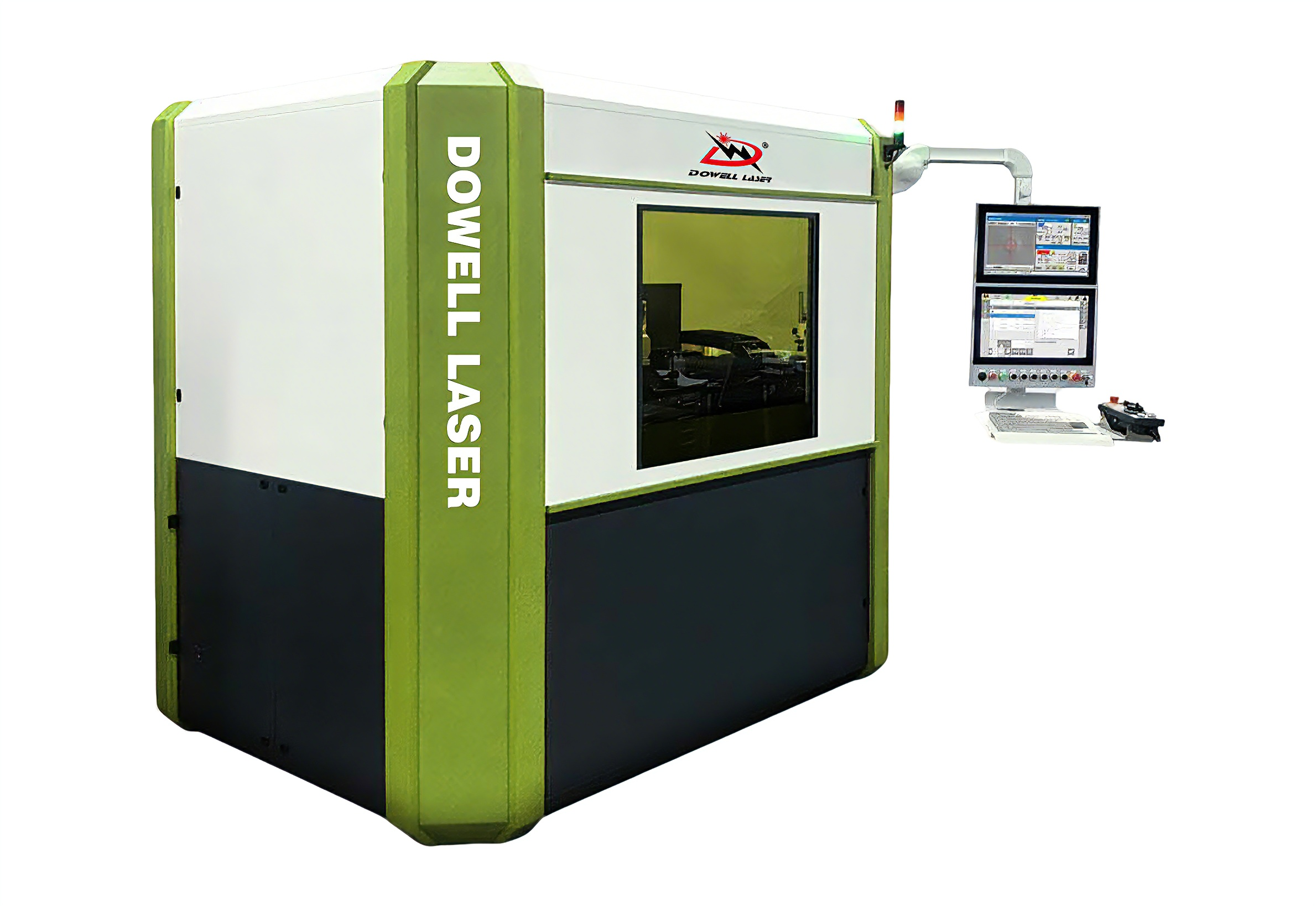

700 water-guided Laser Processing Center

Water-guided laser processing, with its micron-level precision, defines a new height in ultra-precision manufacturing, opening up entirely new possibilities for the development of high-end manufacturing industries!

Product Introduction

This is a 3 axis precision water-guided laser processing center. Based on Dowell Laser’s patented water-guided laser technology, a high-power laser beam is coupled into a water jet thinner than a human hair (30um~80um) and guided to the workpiece for cutting or drilling. This water jet acts both as a “guide” for the laser beam and cools the workpiece, ensuring a clean cut surface with no heat-affected zone.

Application Areas

This water-guided laser technology can process various conductive, semiconductive, and insulating materials, including: aluminum, aluminum nitride, boron carbide, carbon fiber, copper alloys, GdBCO superconducting materials, chromium-nickel-iron alloys, nickel alloys, silicon, silicon carbide, steel alloys, titanium nitride, tungsten, and tungsten carbide.

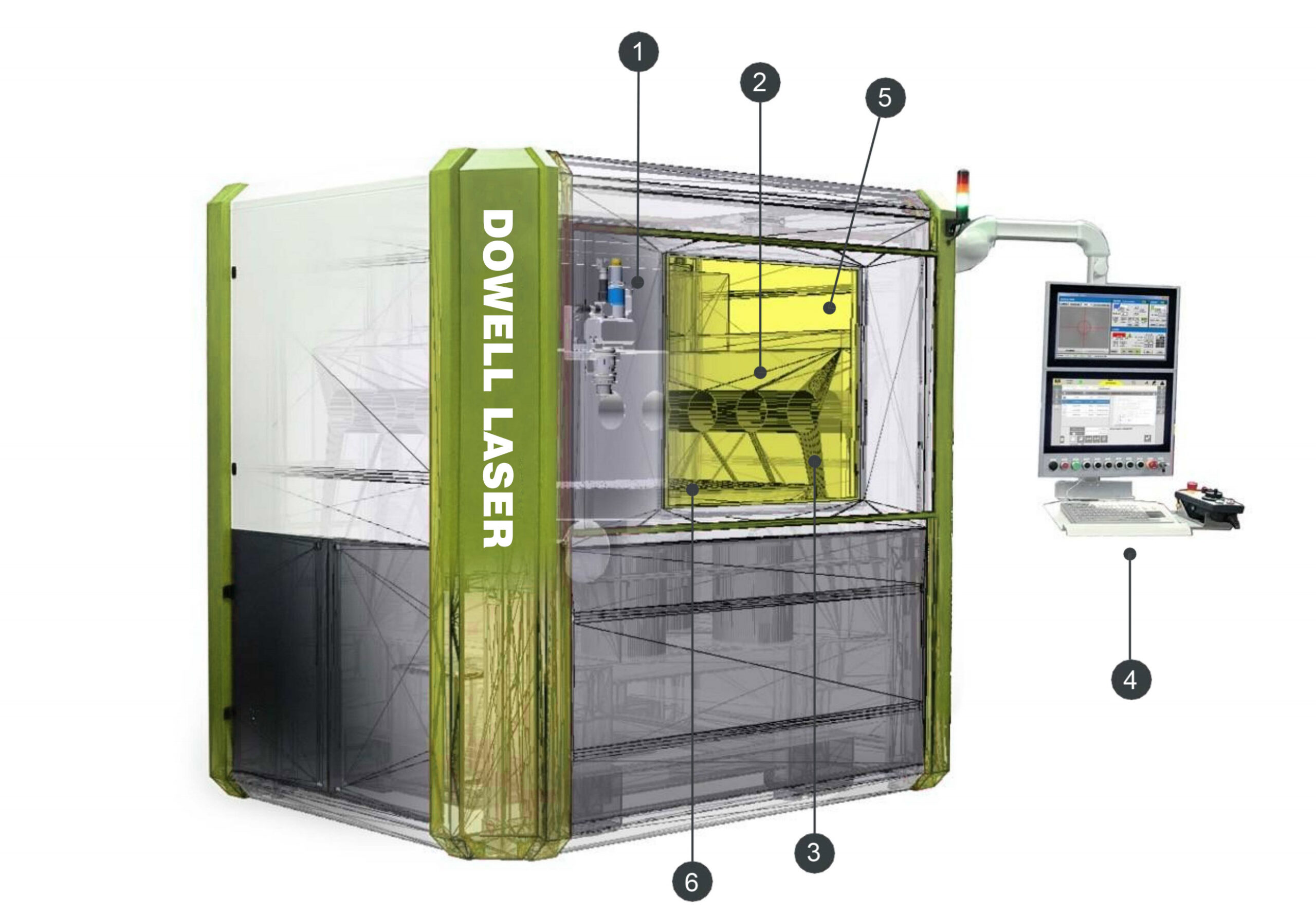

Composition of 700 Water-guided Laser Processing Center

Upgraded across all dimensions from core components to intelligent systems, it integrates high precision, high efficiency, and ease of operation. It is not only a “powerful tool” for ultra-precision machining, but also a “core competitiveness” for enterprises to seize the high-end manufacturing track!

01.

The LJFK45IR waterjet laser head features a quick-change coupling unit and unique jet protection technology.

02.

High-precision gantry-type 3/4/5 axis linear motion system with an integrated natural stone base.

03.

X-axis travel 600mm, Y-axis travel 600mm, Z-axis travel 300mm, capable of machining large parts.

04.

HMI human-machine interface system equipped with two independent displays, one for machine tool control and the other for waterjet process data control.

05.

Extra-large 900*800mm laser safety observation window, providing a clear view of the laser processing process.

06.

Large worktable with over 1000 M6 threaded holes for flexible workpiece fixation and clamping system.

Technical Specifications of 700 Laser Microjet Processing Center

Dowell Laser develops, manufactures, and markets laser systems based on its proprietary waterjet laser technology. Dowell Laser systems are designed to deliver powerful performance for demanding applications while maintaining ease of operation, quick maintenance, and cost-effectiveness.

|

Product Image

|

Product Name

|

Item

|

Описание

|

|---|---|---|---|

|

|

Машина |

Конфигурация |

Natural stone base; Gantry-type 3-axis linear motor structure |

|

|

|

Axis Travel |

X: 600mm linear / Y: 600mm linear / Z: 300mm lead screw |

|

|

|

Positioning Accuracy |

+/-2um (<500mm/s) |

|

|

Повторяемость |

P3S-560 |

+/-0.5um |

|

|

|

Speed and Acceleration |

G0: max. 1500mm/s; G1: max. 1000mm/s; Acceleration: 1G |

|

|

|

Контроллер с ЧПУ |

B&R/Beckhoff |

|

|

|

Dimensions/Weight |

L*W*H = 1600*2000*2250mm / 3500kg |

|

|

Laser Technology |

Machining Technology |

Dowell Laser's proprietary water-guided laser technology, including patented features such as: water and laser coupler, air jet protection, etc. |

|

|

|

Режущая Головка |

|

|

|

|

Laser Type |

Green / Red |

|

|

|

Laser Wavelength |

523 - 1080nm |

|

|

|

Сила |

40 - 10000 W |

|

|

|

Fiber core diameter/beam quality |

50µm/BPP 2.0 typical |

|

|

Water Pump |

Water Pump Type |

High-pressure water pump for water-guided laser processing |

|

|

|

Water Pump Brand |

Dowell Laser AVHPP600 |

|

|

|

Operating Pressure |

50–550 bar, pulse-free water flow |

|

|

|

Water Jet Nozzle Size |

30–80 μm |

|

|

|

Purification Requirements |

Deionized water with three-stage filtration |

|

|

Operating Environment |

Water |

Municipal water (<20°C) or distilled water in a tank; consumption approximately 1 L/hour |

|

|

|

Compressed Air |

6-8 bar, dry, oil-free air; pump consumption approximately 400 Nl/hour; processing consumption approximately 300–900 Nl/hour |

|

|

|

Power Supply |

1 * 380V–415V, +/-10%, 3P–N, 1 * 3 * 400V |

Note: Dowell Laser holds over 20 patents and has patents pending related to its core technologies, including unique patented technologies such as high-power laser coupling methods, air jet protection systems, and easy-to-maintain laser coupling unit designs.

Based on independent innovation

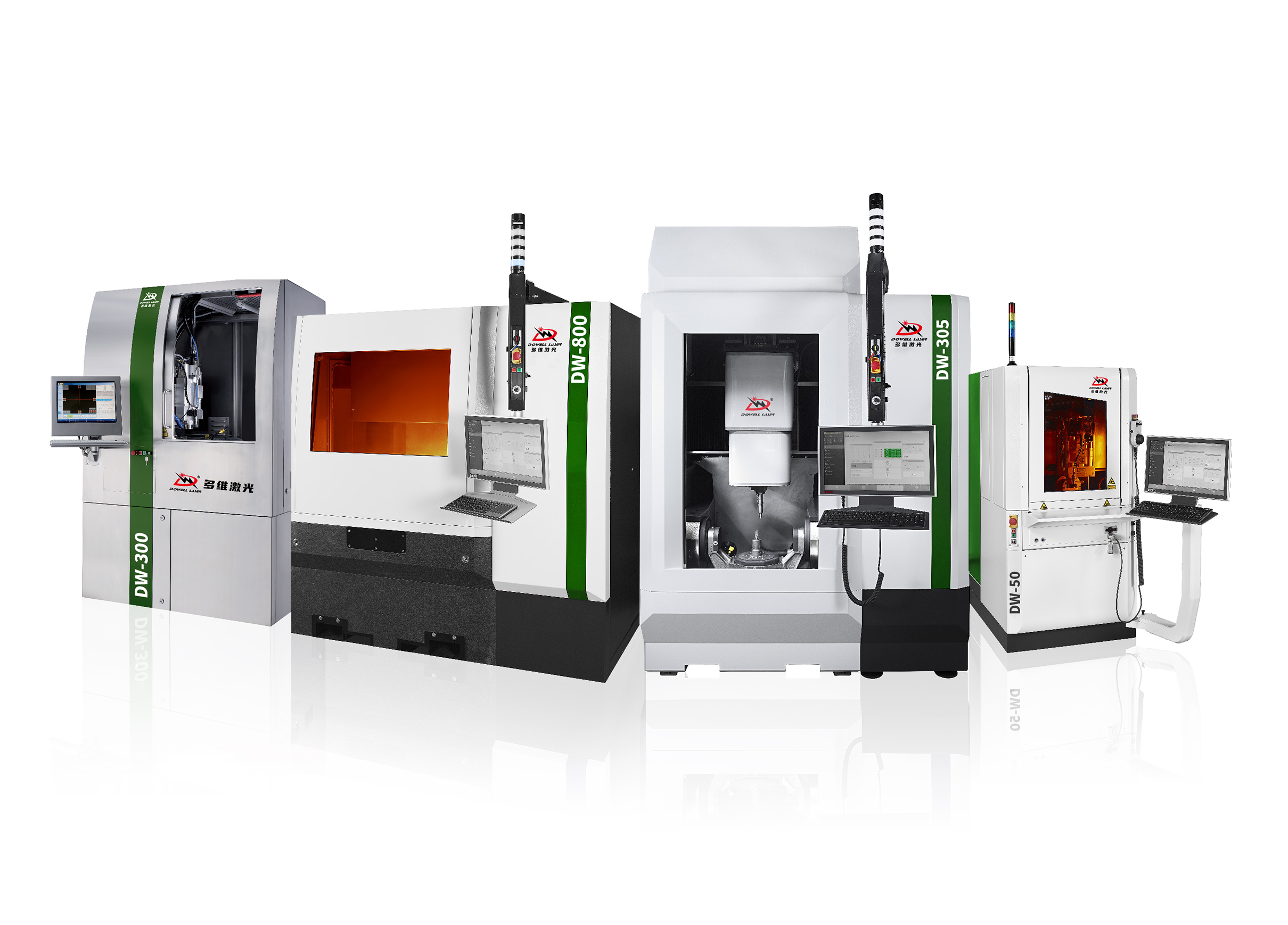

The Complete Solution of Water Guided Laser Small to Medium Format Processing Ideal-Tools

This innovative “laser + water jet” synergistic mechanism precisely confines the laser beam within a hair-thin water jet using the principle of total internal reflection, achieving a true “cold processing” experience: no heat-affected zone, no burrs, and no microcracks. The cutting surface roughness is as low as Ra 0.1-0.3μm, meeting stringent standards without the need for secondary polishing. The long working distance design eliminates the need for repeated focusing, and parallel cutting ensures processing consistency. Even when dealing with ultra-hard/brittle materials such as silicon carbide (SiC), ceramic matrix composites (CMC), and PCD diamond, it achieves smooth cutting and complex shaping, completely solving the problems of thermal damage and material limitations inherent in traditional laser processing.

Features & Advantages

High-precision Water Jet Guided Laser Machining

- Robotic Automation It involves the use of software robots or bots to automate repetitive, rule-based tasks.

- Machine Learning A subset of AI that focuses on developing algorithms and models.

- Cloud Automation The process of automating everything within cloud computing environments.

- Development & Operations Set of practices that combine software development and IT operations to streamline lifecycle.

Coupling Devices and Techniques

The laser beam coupled into the water jet fiber needs to undergo optimized optical transformation so that the laser beam spot meets the coupling requirements. A relatively mature solution is to focus the Gaussian beam through a convex lens before it enters the water jet fiber. This structure is simple, practical, and flexible, making it suitable for various applications.

Benefits: The coupling technology ensures that the laser beam undergoes total internal reflection at the air-water interface. The beam can be guided over a distance of up to 10 cm, enabling parallel, high-aspect-ratio cuts without the need for multiple focusing or distance control.

Enclosed Protective Cover

Dowell Laser utilizes an enclosed protective cover and a special machine door design. Openings are specifically designed at the top and bottom of the machine’s protective cover to strictly control airflow within the processing area, thus maintaining stable and consistent thermal characteristics within the processing zone.

Benefits: Stable and consistent machine thermal characteristics, resulting in repeatable workpiece accuracy.

All axies are equipped with linear encoders.

The X, Y, and Z basic axes, as well as the U and V taper machining axes, are all equipped with linear encoders to ensure high positioning accuracy.

Laser Cleaning Machine Price: A Comprehensive Guide

1. Ultra-high pitch accuracy

2. Ultra-high hub accuracy is also achieved when cutting tapered workpieces online.

linear optical encoder 1

linear optical encoder 1 Industrial Distilled Water

The water entering the water-guided laser processing system is industrial-grade distilled water.

The system includes a built-in water treatment system for all necessary purification processes.

Due to the “hair-thin” jet, water consumption is low: typical water pressure range is 100-600 bar. Water consumption at 300 bar is approximately 1-3 liters/hour.

Considering the laser beam diameter, the combined force exerted by the laser beam is negligible (<0.1 N).

Selection Guide & Comparison Tool

The LCS-50 system is ideal for precision machining of diamond cutting tools, watch components, and other small parts requiring precision cutting, drilling, grooving, slicing, and 3D machining.

The LCS 150 is a general-purpose laser cutting system designed for micromachining applications, such as cutting, drilling, or grooving in various industrial sectors. This system can utilize different laser powers.

The LCS 305 is a laser microjets LMJ® machining system designed for automated production of large-size cutting tools, multi-tooth diamond tools, and other 3D machining applications. Featuring a uniquely designed five-axis linkage, its highly dynamic axial machining enables precision machining with maximum accuracy and speed simultaneously.

Unsure if the parameters are suitable? Click "Comparison Results" Get Exclusive Selection Assessment Form, fill in your processing materials/dimensions/accuracy requirements, and receive a customized solution within 10 minutes.

Product

Outlooks

Version

LCS 50-3

LCS 50-5

LCS 150

LCS 305

Working Volume (mm) (W x D x H)

50 x 50 x 50

50 x 50 x 50

150 x 150 x 100

500 x 380 x 380

Accuracy (µm)

+/- 3

+/- 3

+/- 5

+/- 5

Repeat Positioning Accuracy (µm)

+/- 1

+/- 1

+/- 2

+/- 2

Number of Axis

3 Axis

5 Axis

3/4/5 Axis

5 Axis

Laser Type

Diode-pumped solid-state neodymium: YAG, Pulsed

Diode-pumped solid-state neodymium: YAG, Pulsed

Diode-pumped solid-state neodymium: YAG, Pulsed

Diode-pumped solid-state neodymium: YAG, Pulsed

Wavelength (nm)

532

532

532/1064

532

Main Unit Dimensions (mm) (W x D x H)

800 x 1200 x 1650

800 x 1200 x 1650

1050 x 800 x 1870

1800 x 1950 x 2610

Control Cabinet Dimensions (mm) (W x D x H)

700 x 2300 x 1600

700 x 2300 x 1600

700 x 2300 x 1600

700 x 2300 x 1600

Frequently Asked Questions

Addressing your purchasing concerns and lowering decision-making barriers

Equipment investment is high, how can I ensure a return on investment?

Can the technology be successfully implemented for complex workpiece processing?

What if after-sales service is inadequate?

Explore the Latest News

from Our Event

Stay updated with the latest news, insights, and behind-the-scenes stories from our event through our dedicated event blog section.

Ultra precision performance, high cost-effectiveness

Consult Water-jet Guide Laser Experts

Want to start and expand high-value microfabrication business, but have many concerns when looking for profitable water guided laser processing machines? Worried about equipment not keeping up with production pace, exceeding budget, and delivery quality not meeting standards?

Choosing the Dowell Laser water jet guide laser production solution allows you to avoid various traps on the path of entrepreneurship and development, and steadily seize the high-end processing track!