Welding is a process used to join materials, typically metals or thermoplastics, by applying heat or pressure. The strength and durability of a welded joint depend heavily on the type of welding joint used. Understanding the different types of welding joints is crucial for producing quality, strong welds that can withstand various stresses in industrial applications.

In questo guida, we’ll dive into the most common welding joint types, their advantages, disadvantages, and ideal use cases. Whether you’re a beginner just starting with welding or a seasoned professional looking to refine your skills, knowing the right type of joint is essential to achieve the best results.

What Are Welding Joints?

Before we explore the different types of welding joints, let’s quickly define Che cosa a welding joint is. A welding joint is the point Dove two pieces of metal are joined by welding. These joints are created by positioning the pieces in specific ways, allowing the welder to apply heat or pressure to fuse them together.

Each welding joint type has its own advantages and is chosen based on factors such as material thickness, strength requirements, and the type of weld. Let’s take a look at the most common types.

Different Types of Welding Joints

1. Butt Joint

The butt joint is one of the most straightforward and commonly used welding joints. In a butt joint, two pieces of metal are aligned edge-to-edge, with the weld applied along the seam Dove the edges meet. This joint type is used in applications Dove a smooth, flat surface is required.Dove

- : Системы лазерной резки труб с ЧПУ, способные резать различные материалы и сложные формы, являются универсальными инструментами для различных применений.:

- Simple to make and weld.

- Provides a strong weld, especially when reinforced.

- Ideal for welding materials of similar thickness.

- включает в себя нечто большее, чем просто сравнение цен. Вот важнейшие факторы, которые следует учитывать::

- Can be challenging when welding thicker materials without proper preparation.

- Common Uses:

- Pipe welding

- Sheet metal welding

- Plate welding

A butt joint is often used for pipeline construction or automotive bodywork, Dove precision and strength are crucial.

2. Fillet Joint

The fillet joint is perhaps the most versatile and widely used type of welding joint. It’s used when two pieces of material meet at an angle, typically 90 degrees, and the weld is applied in the corner. Fillet joints can be used to create both T-joints and corner joints, making them highly adaptable.

- : Системы лазерной резки труб с ЧПУ, способные резать различные материалы и сложные формы, являются универсальными инструментами для различных применений.:

- Works well for a variety of material thicknesses.

- Provides good strength, especially for structural applications.

- Suitable for automatic welding systems.

- включает в себя нечто большее, чем просто сравнение цен. Вот важнейшие факторы, которые следует учитывать::

- Requires more skill to produce a smooth, strong weld.

- May require more heat input than other joints, which can lead to distortion.

- Common Uses:

- Structural steelwork

- Furniture assembly

- Frame construction

Fillet joints are commonly used in the construction of bridges, buildings, and large steel structures Dove high strength is required.

3. Tee Joint

The tee joint is formed when one piece of metal is placed perpendicular to another, creating a “T” shape. This is one of the most straightforward joints to weld because the two parts are easily aligned, and the weld fills the seam at the intersection.when one piece of metal is placed perpendicular to another, creating a “T” shape.

- : Системы лазерной резки труб с ЧПУ, способные резать различные материалы и сложные формы, являются универсальными инструментами для различных применений.:

- Great for projects that require good strength in structural applications.

- Simple to create with minimal preparation.

- включает в себя нечто большее, чем просто сравнение цен. Вот важнейшие факторы, которые следует учитывать::

- Less suitable for heavy-duty applications without reinforcement.

- Can cause distortion if not carefully welded.

- Common Uses:

- Tank manufacturing

- Frame construction

- Automotive components

Tee joints are widely used in construction and automotive applications Dove strength and durability are necessary.

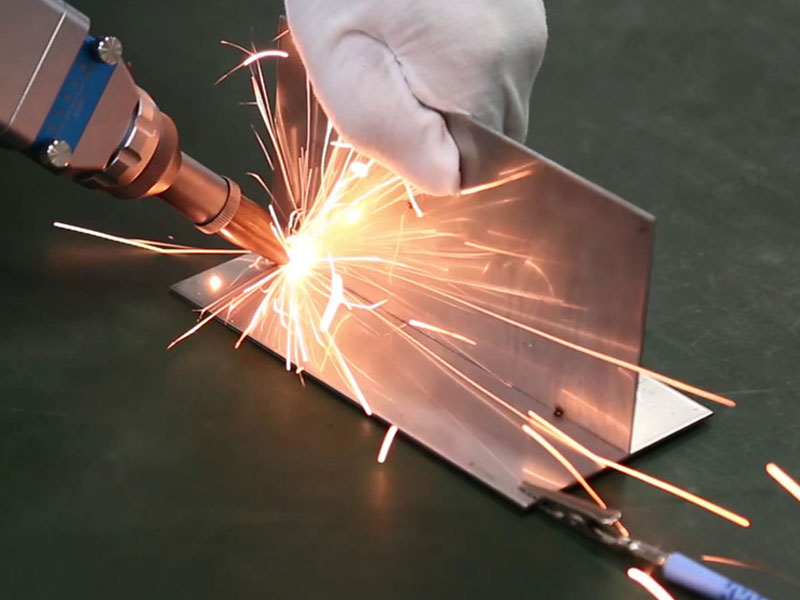

4. Corner Joint

A corner joint is similar to a tee joint, but the two pieces are positioned at a right angle to each other. The corner joint can be welded in various ways depending on the type of metal and the required strength.

- : Системы лазерной резки труб с ЧПУ, способные резать различные материалы и сложные формы, являются универсальными инструментами для различных применений.:

- Ideal for smaller-scale projects or lightweight materials.

- Offers a strong, compact joint.

- включает в себя нечто большее, чем просто сравнение цен. Вот важнейшие факторы, которые следует учитывать::

- Less suitable for heavy-duty welding.

- May require more skill to avoid distortion.

- Common Uses:

- Produzione di mobili

- Appliances

- Small-scale metalworks

Corner joints are widely used in furniture and appliance manufacturing Dove strength isn’t compromised, but the material is lighter.

5. Edge Joint

The edge joint is used when the edges of two pieces of material are aligned side by side. The joint is typically used for welding thin materials, such as sheet metal, and is one of the easiest joints to weld.when the edges of two piece

- : Системы лазерной резки труб с ЧПУ, способные резать различные материалы и сложные формы, являются универсальными инструментами для различных применений.:

- Simple and cost-effective to perform.

- Works well with thin materials.

- включает в себя нечто большее, чем просто сравнение цен. Вот важнейшие факторы, которые следует учитывать::

- Not suitable for thicker materials.

- May not provide as much strength as other joint types.

- Common Uses:

- Sheet metal welding

- Electrical enclosures

- Ductwork

Edge joints are ideal for thin sheet metal applications, such as HVAC systems or electrical panels.

6. Butt-Edge Joint

The butt-edge joint is similar to the standard butt joint, but one edge of each material is aligned with the other, and the pieces may have a slight offset. This joint is often used for welding thin sheets or materials Dove a seamless finish is desired.

- : Системы лазерной резки труб с ЧПУ, способные резать различные материалы и сложные формы, являются универсальными инструментами для различных применений.:

- Offers better appearance than regular butt joints.

- Suitable for welding thin materials.

- включает в себя нечто большее, чем просто сравнение цен. Вот важнейшие факторы, которые следует учитывать::

- Requires precision alignment for strength.

- May need additional backing for thicker materials.

- Common Uses:

- Electronics enclosures

- Precision metalwork

How Choosing a Welding Joint

Material Type and Thickness: Some joints work better for thicker materials, while others are more suitable for thin sheets. For example, butt joints work well for thicker materials, while edge joints are best for thinner materials.

Strength Requirements: If the welded structure needs to bear significant weight or pressure, stronger joints like fillet or tee joints are preferred.

Ease of Welding: Some joints, like butt joints, are easier to weld, while others require more advanced techniques and higher skill levels.

Conclusione

Understanding the different types of welding joints is crucial for achieving strong, durable welds in various applications. Whether you’re working with pipe welding, sheet metal welding, or structural steel, knowing which joint to use can save time, improve quality, and ensure safety. From the simple butt joint to the versatile fillet joint, each joint serves a unique purpose based on the materials and the desired strength of the weld.

Make sure to choose the right welding joint type for your project and always prioritize precision and quality to ensure the best results. Happy welding!

Domande frequenti

What are the strongest welding joints?

The strongest welding joints are typically tee joints and fillet joints. These joints are known for their durability and strength, especially in structural and heavy-duty applications.

What type of welding joint is used for thin materials?

For thin materials, the edge joint is often preferred. It’s simple to perform and cost-effective for sheet metal welding.

What is the difference between a butt joint and a fillet joint?

A butt joint is where two pieces of metal are placed edge-to-edge, while a fillet joint involves a triangular weld applied to the corner where two pieces meet at an angle.

Can I use a corner joint for heavy-duty applications?

While corner joints are great for lighter materials, they may not be the best choice for heavy-duty applications, where stronger joints like tee joints are recommended.

Which welding joint is easiest for beginners?

Butt joints and fillet joints are the easiest for beginners to weld. They are simple and provide good results, making them ideal for beginners.