In case you are searching for a fitting extensive pipe laser cutting endeavor and aiming to strike a balance between quality and cost-effectiveness, laser cutting technology offers the potential to enhance cutting efficiency, reduce expenses, and boost productivity by up to 50%.

Develop of Large Tube Laser Cutting Technology

Since its inception, the big tube laser cutting method has made great strides. At first, lasers were used to cut thin materials such as sheet metals due to their limited capabilities. However, technology advancements have seen the development of large pipe laser cutters that are capable of handling thicker and larger pipes very easily.

Laser cutting demands on huge tubes in the industrial market have this requirement high and it should be done efficiently and accurately. To simplify the manufacturing process and save time to raise efficiency levels, it has become clear that Large tube laser cutting machines offer a way out of this problem. Such machines can cut thick pipes with a lot of precision, thus enabling manufacturers to complete work quickly but in an efficient manner.

Fiber Lasers’ Development: Laser devices are becoming more powerful which means that they can cut through thicker materials with ease. This is a game changer for manufacturers who can now work with a wider range of materials and create more intricate designs.

The advancement in software used for laser cutting is essential in enhancing the capability of large tube laser cutter machines. Nowadays, modern software programs enable manufactures develop patterns and complex designs that are executed precisely by means of laser-cutting equipment. However, at the early ages of laser cutting technology, one could not exercise such control or attain such precision on these products.

Benefits of Large Tube Laser Cutting

Precisely cut thick tubes: Manufacturers are able to create complex designs that would be difficult or impossible to achieve using traditional methods.

Cost Effectiveness: Large pipe laser cutters can complete projects faster than traditional methods, resulting in significant cost savings. The precision and accuracy of laser cutting reduces material waste, further reducing costs.

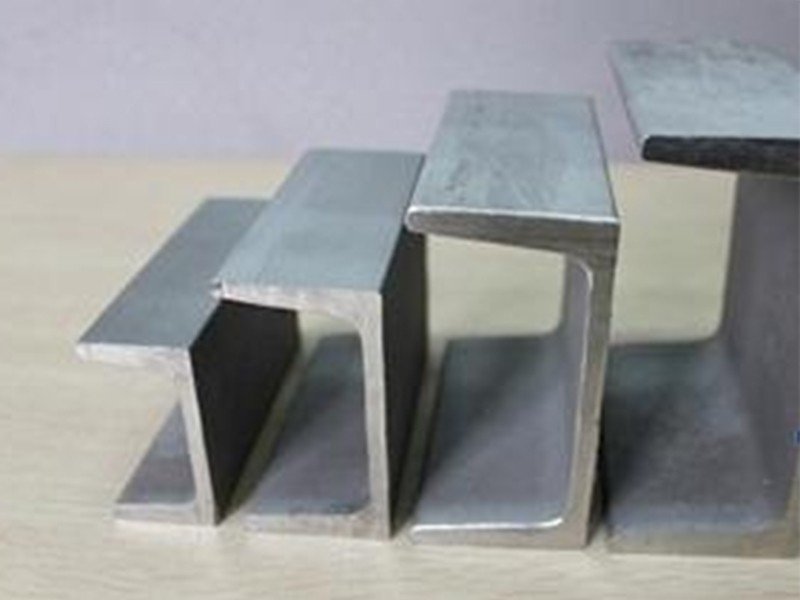

Cutting flexibility: These machines can handle a variety of materials, including stainless steel, aluminum, and even specialty alloys. This versatility makes laser cutting of large pipes a viable option for a variety of industries.

Precision and Accuracy in Big Tube Laser Cutting

Precision and accuracy are two key factors that differentiate cnc tube laser cutting machine from traditional cutting methods. Laser cutters use a focused beam of light to cut materials with extreme precision. This allows complex designs and complex shapes to be created easily.

Measured by tolerance level, which refers to the allowable deviation from the required dimensions. Laser cutters are capable of a high level of precision, often within a few thousandths of an inch. This level of accuracy is critical for industries that require tight tolerances, such as aerospace and medical device manufacturing.

Repeatability. Once a design is programmed into the machine’s software, it can be reproduced with consistent results time and time again. This is especially important for manufacturers who need to produce large quantities of the same parts.

Cost Efficiency: The Key Advantage

The cost effectiveness of stock laser cut large pipes is one of its main advantages. More traditional ways like sawing or milling take a long time and are more labour intensive hence increasing production costs. The machines for cutting thick tubes with lasers on the other hand, offer a quicker alternative.

With a focused beam to cut material, big tube laser cutters can complete projects faster than traditional methods. This reduces labor costs as well as allowing manufacturers to get projects done quickly and thus making them more productive while at the same time decreasing lead times.

Large pipe laser cutting machines are extremely accurate and can help minimize the wastage of materials. When it comes to saw blades or milling cutters that have a certain width this often leads to considerable loss in terms of raw materials used. Laser cutting, however, has narrower heat affected zones which in turn results in less waste and maximizes efficiency.

Industry Applications of Large Format Laser Cutting

CNC large laser tube cutting services technology is widely used in industries such as automotive, aerospace, construction and manufacturing.

In the automotive industry: Big tube laser cutting is used in various applications such as exhaust systems, chassis parts and structural parts. The precision and accuracy of laser cutting make it ideal for producing high quality automotive parts.

In the aerospace industry: Laser cutting of large tubes is used to make components such as turbine blades and aircraft frames. The ability to accurately cut thick materials makes laser cutting an important tool in aerospace manufacturing.

In the construction industry: used to manufacture beams, columns, and other structural components using laser cut samples. The speed and precision of laser cutting allow construction projects to be completed more efficiently.

Large tube laser cutting services are also widely used in general manufacturing processes. It can be used to produce a variety of products such as furniture, appliances, and machinery parts. The versatility of this technology makes it a valuable asset to any manufacturing facility.

How to Choosing a Large Diameter Tube Laser Cutting Services

When choosing a large tube laser cutting services provider, several factors should be taken into consideration:

Experience and Expertise: It is important to choose a service provider with a proven track record in laser cutting large pipes. Find a company that has experience handling projects similar to yours.

Capabilities: Consider the capabilities of the service provider. Do they have the equipment and software needed to handle your project? Can they use the materials you need?

Quality Control: Look for a service provider with robust quality control processes. This ensures your project will be completed with detailed laser cut parts to the highest standards.

Turnaround time: Consider the turnaround time offered by your service provider. How quickly can they complete your project? This is especially important if you have a tight deadline to meet.

Costo: While price is not the only determining factor, it is important to choose a service that offers competitive pricing.

How to improve Large Tube Laser Cutting Projects

To maximize efficiency in large tube laser cutting projects, several strategies can be employed:

- Optimize design: Ensure that you work closely with your design team to optimize designs for laser cutting by reducing the number of unnecessary cuts and material wastage.

- Batch processing: Whenever possible, process parts in batches to reduce setup time thus maximizing productivity.

- Maintain equipment: Regularly maintain and calibrate the laser cutting machines for them to operate at their optimum level.

- Streamline workflow: Streamline all your workflow procedures and identify bottlenecks based on analysis. Implement measures aimed at improving these processes and making them more efficient overall.

Sustainability and Environmental Impact of Large Tube Laser Cutting

Laser cutting of large tubes presents sustainable advantages to traditional cutting methods including:

- Less wastage: Laser cutting creates a thin kerf width thus leading to less material loss. This in turn makes the manufacturing process less harmful to our environment.

- Power saving: The laser cutters perform power saving functionalities compared to other traditional ways of cutting.

- Reduced emissions: Laser cutting produces fewer emissions than traditional techniques such as sawing or milling, which helps in creating a cleaner and healthier working environment.

Conclusion:

Large tube laser cutting is a game changer for manufacturers in that it is an accurate, adaptable, and cost-effective solution to employment on large projects. Furthermore, choosing an appropriate contractor or optimizing ones processes can enhance the advantages obtained. Nevertheless, through careful planning, these can be overcome. Plus, it’s even more eco-friendly than the traditional manner of cutting.

FAQ

What do you need to know about a fiber laser tube cutting machine?

A fiber laser tube cutting machine is a large tube laser cutting machine that uses a fiber laser as its cutting tool. The fiber laser has distinguished itself as one of the most efficient lasers and for having an excellent beam quality which makes it good for precision cutting applications.

One of the biggest advantages of fiber laser tube cutting machines is their ability to easily cut through materials. This includes aluminum, stainless steel, copper or brass.

What is the laser tube cutting process?

The process of laser tube cutting is basically using a concentrated light beam (laser) to cut tubes or pipes composed of different kinds of materials. The process starts by designing the intended shape or pattern, which is after that programmed into the software used in the laser cutter.

The metallic pipe is loaded onto the machine and material receives laser rays on it. In this case, intense heat from the laser melts or vaporizes material along its designated path of cutting thereby resulting in a neat and accurate cut.

Can a laser cutter effectively cut sheet metal?

Yes, a laser cutter can effectively cut sheet metal. In fact, laser cutting has become one of the most popular methods for cutting sheet metal due to its precision and versatility.