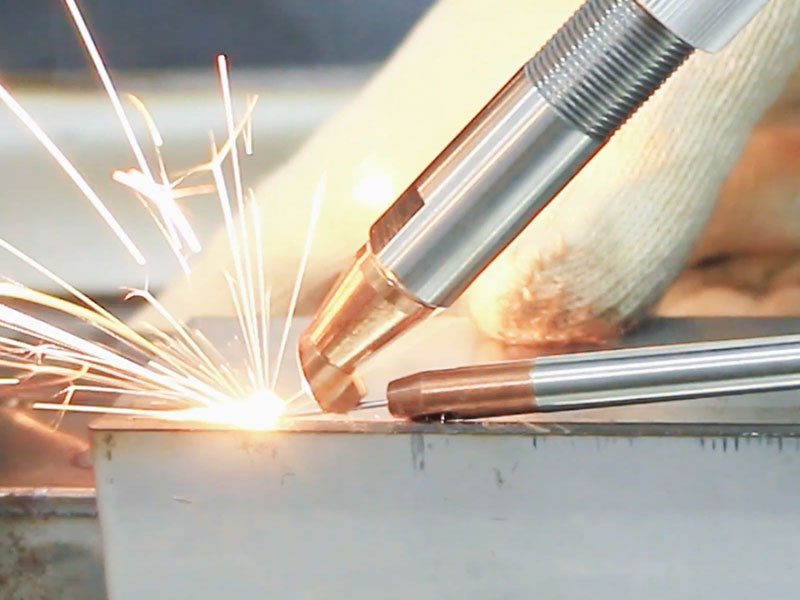

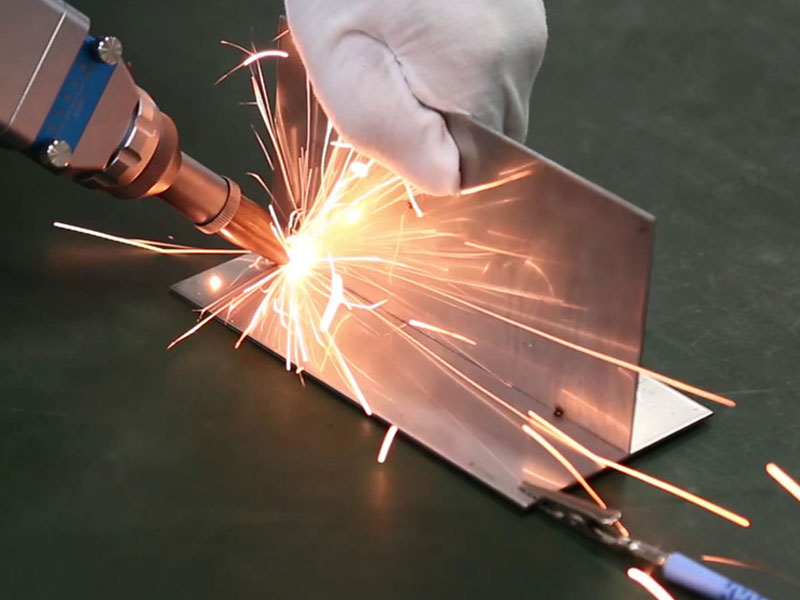

With the rapid development of laser welding technology, handheld laser welding machines are increasingly used in the industrial market, but many customers know little about laser welding safety. Now this article will tell you some of the most complete guides on laser welding safety, I hope it will be helpful to you.

Hazards of Laser Welding

Hazards of laser radiation:

Eye damage: Laser radiation can directly damage the retina, causing serious consequences such as blurred vision and permanent blindness. Even short exposure can cause eye burns.

Skin damage: Laser radiation can cause skin burns, redness, pigmentation, etc. Long-term exposure may cause skin cancer.

A study revealed that laser welding workers who did not wear protective glasses experienced symptoms of corneal damage and vision loss within a short period of time.

Hazards of high voltage electricity:

Risk of electric shock: Laser welding equipment usually requires a high voltage power supply. Once exposed wires or equipment are touched, electric shock accidents are very likely to occur.

A maintenance worker was electrocuted to death due to careless operation while repairing laser welding equipment.

What Are the Laser Welding Safety Requirements?

Equipaggiamento per la protezione personale:

- Laser welding safety glasses (laser protective glasses): Choose appropriate protective glasses according to the laser wavelength and power to ensure that they can effectively block laser radiation.

Protective clothing: Choose protective clothing that is resistant to high temperature, wear-resistant and breathable to protect the skin from laser radiation and high temperature burns. - Respiratory protection: When harmful gases are generated during welding, a gas mask or air respirator should be worn.

Equipment protection:

- Laser protective cover: Install a laser protective cover to prevent laser beam scattering and protect surrounding personnel.

- Emergency stop device: Set an emergency stop button to quickly cut off the power supply in an emergency.

- Interlocking device: When the protective cover is opened, the laser automatically stops working.

Environmental protection:

- Ventilation system: Ensure that the workplace is well ventilated and harmful gases and smoke are discharged in time.

- Firefighting facilities: Equipped with fire extinguishers and other firefighting facilities to prevent fires.

Laser welding safety regulations and standards

National standards: my country has issued a number of national standards on laser safety, such as the “Laser Radiation Safety Management Regulations”.

Industry standards: The laser welding industry also has corresponding safety standards, which stipulate the requirements for the design, manufacture, installation and use of laser welding equipment.

International standards: The International Electrotechnical Commission (IEC) has issued a number of international standards on laser safety, which provide references for laser safety regulations in various countries.

Conclusione

Laser welding is an efficient processing technology, but safety always comes first. Only by strictly abiding by the safety operating procedures and taking comprehensive protective measures can the risk of accidents be minimized. As laser welding practitioners, we have the responsibility and obligation to be responsible for our own safety and the safety of others. Let us work together to create a safe, healthy and harmonious laser welding working environment.