For many customers who want to buy laser rust removal machines, they must first understand what laser rust removal does, what its working principle is, and what its benefits are. This article will tell you these.

What Is Laser Rust Removal?

Laser rust removal is an innovative and effective method for eliminating rust from various surfaces. Unlike traditional methods that involve harsh chemicals or abrasive techniques, laser rust removal utilizes a high-powered laser beam to vaporize rust without damaging the underlying material.

Laser Rust Removal Principle

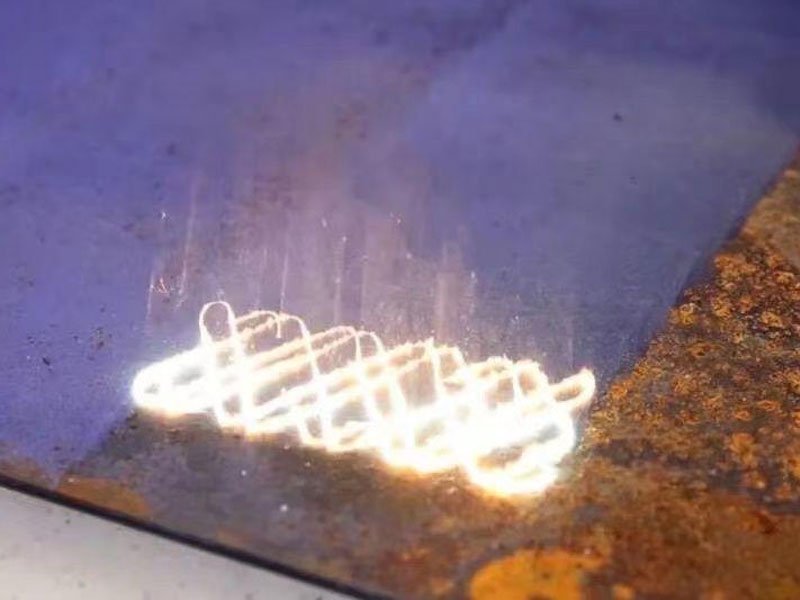

The laser beam is precisely directed onto the rusted area, generating intense heat that instantly vaporizes the rust particles. This process is highly localized, minimizing the impact on the surrounding material. The vaporized rust is then extracted through a vacuum system, leaving the surface clean and free of corrosion.

Laser rust removal offers several advantages over conventional methods. Firstly, it is a non-contact process, eliminating the risk of surface damage or contamination. Secondly, it is highly precise, allowing for the removal of rust from intricate or delicate surfaces. Thirdly, it is environmentally friendly, as it does not involve the use of hazardous chemicals.

The Process of Laser Rust Removal:

- Surface Preparation: The rusted surface is cleaned to remove any loose debris or contaminants.

- Laser Application: The laser beam is directed onto the rusted area, vaporizing the rust particles.

- Vacuum Extraction: The vaporized rust is extracted through a vacuum system.

- Post-Treatment: The cleaned surface may require additional treatment, such as polishing or coating, to restore its original appearance.

Applications of Handheld Laser Rust Remover

Laser rust removal is suitable for a wide range of materials, including metal, plastic, wood, and stone. It is commonly used in industries such as automotive, produzione, restoration, and construction.

Laser Rust Removal Principle

The principle behind laser rust removal lies in the interaction between the laser beam and the rust particles. Quando a high-powered laser beam is directed at the rusted surface, it generates intense heat that causes the rust to vaporize. This vaporization process effectively removes the rust without damaging the underlying metal.

Types of Lasers for Laser Rust Removal

- NdLasers: Suitable for removing thick and heavily oxidized rust.

- Fiber Lasers: Compact and efficient, suitable for both industrial and commercial applications.

- CO2 Lasers: Ideal for removing thin layers of rust and surface contaminants.

- Excimer Lasers: Effective for removing rust from non-metallic surfaces and fine cleaning.

Advantages & Disadvantages of Laser Rust Removal

Vantaggi:

- Precision and Control: Targeted treatment without damaging the underlying material.

- Speed and Efficiency: Rapid process, reducing labor time and costs.

- Non-Contact Process: No risk of surface damage or contamination.

- Environmentally Friendly: No harmful chemicals or waste.

- Versatile Applications: Suitable for various industries and materials.

Disadvantages:

- Costo: Equipment can be expensive.

- Skill Requirement: Requires specialized training.

- Surface Roughness: May create a slightly roughened surface.

- Limited Depth Penetration: Less effective for deep-seated rust.

- Safety Concerns: Requires proper safety precautions.

Benefits of Laser Rust Removal

- Precisione: Removes rust without damaging the underlying material.

- Efficienza: Reduces labor time and costs.

- Environmentally Friendly: No harmful chemicals or waste.

- Superior Results: Ensures complete rust removal and prevents future corrosion.

- Aesthetic Advantages: Restores the original appearance of surfaces.

Applications of Handheld Laser Rust Removers

- Industria automobilistica: Restoring rusted car parts.

- Marine Industry: Removing rust from boats and marine equipment.

- Construction Industry: Cleaning and preparing metal surfaces.

- Industrial Machinery: Removing rust from machinery and tools.

- Historical Restoration: Restoring artifacts and structures.

Cost of Portable Laser Rust Removal Machines

Factors Influencing Cost:

- Laser Power: Higher power increases cost.

- Wavelength: Different wavelengths for specific materials.

- Portabilità: Portable systems are more expensive.

- Brand and Features: Advanced features and reputable brands cost more.

Cost Range: $10,000 to $50,000, depending on power, features, and brand.

Laser Rust Removal Businesses

Choosing a Business:

- Experience and Expertise: Look for proven track records and skilled technicians.

- Attrezzatura: Ensure high-quality laser systems.

- Sicurezza: Verify adherence to safety standards.

- Customer Servizio: Choose responsive and professional businesses.

Comparison with Traditional Rust Removal Techniques

Traditional Techniques:

- Sandblasting: Abrasive and can damage metal.

- Chemical Stripping: Hazardous and requires proper disposal.

- Wire Brushing: Labor-intensive and can leave scratches.

Advantages of Laser Rust Removal:

- Precisione: High precision without damaging surrounding metal.

- Non-Abrasive: Preserves metal surface.

- Environmentally Friendly: No hazardous waste.

- Velocità: Fast and efficient process.

- Versatilità: Suitable for various metals and applications.

Conclusione

Laser rust removal is a superior alternative to traditional techniques, offering precision, non-abrasiveness, environmental friendliness, speed, and versatility. Its applications extend to a wide range of industries, making it an indispensable tool for rust removal and metal surface restoration.