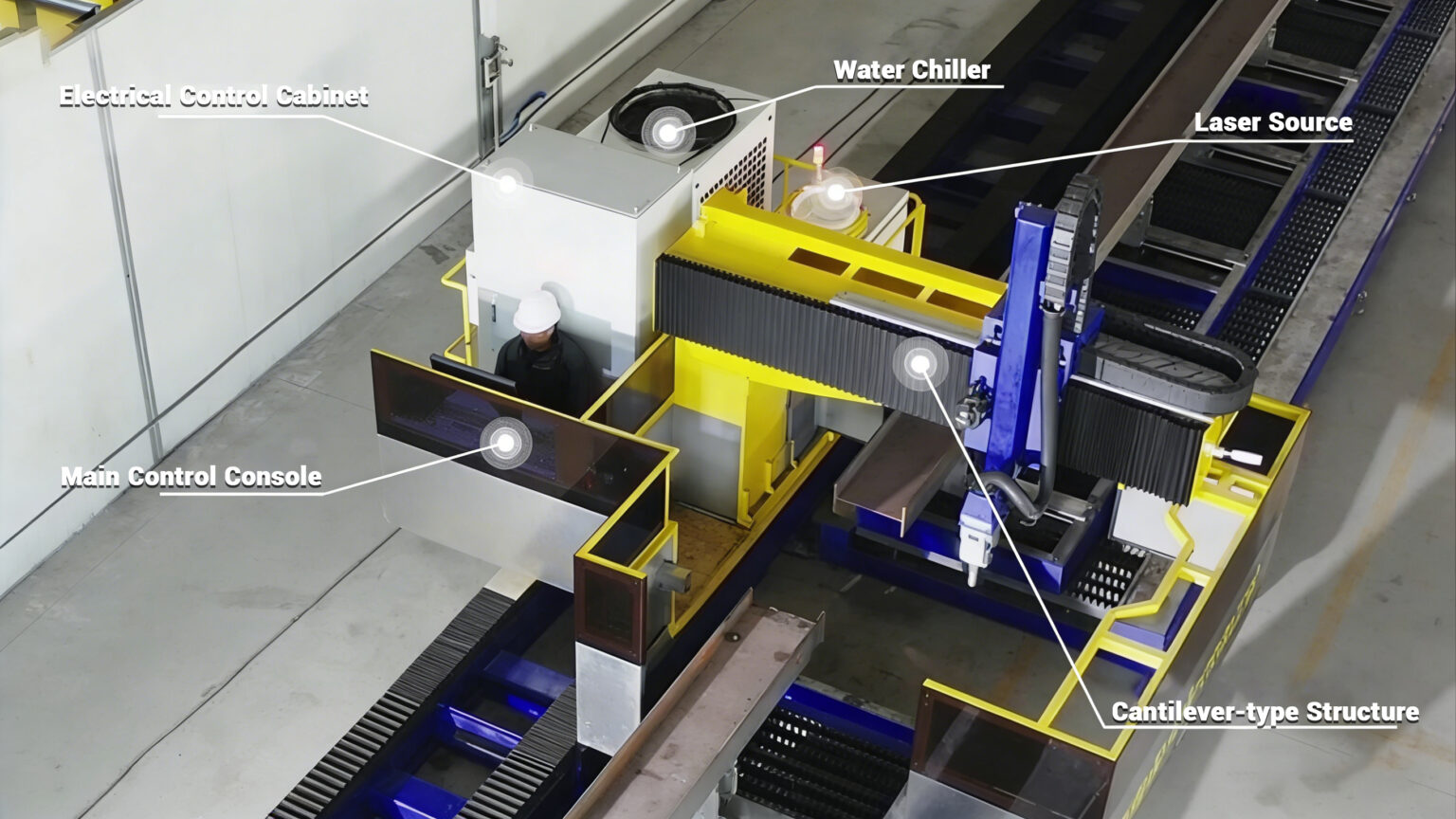

Cantilever-type H Beam Steel Section Laser Processing Center

The 18m ultra-long workspace, 5-axis one-pass cutting / drilling / beveling / marking, 8-ton load capacity, ±0.03mm precision. Weld-ready results, 70% faster production, zero repositioning. Ideal for bridge, high-rise, heavy machinery structural fabrication.

Production Purpose

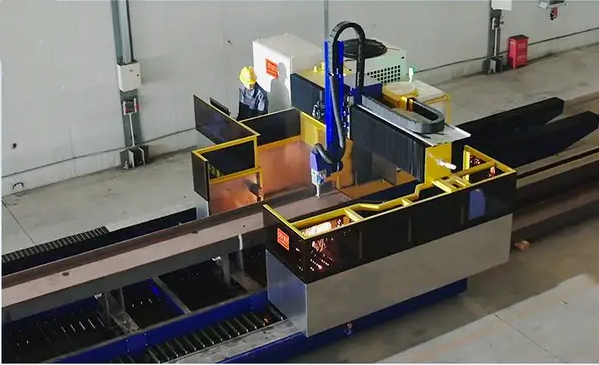

DW Series Cantilever-type Steel Laser Processing Center

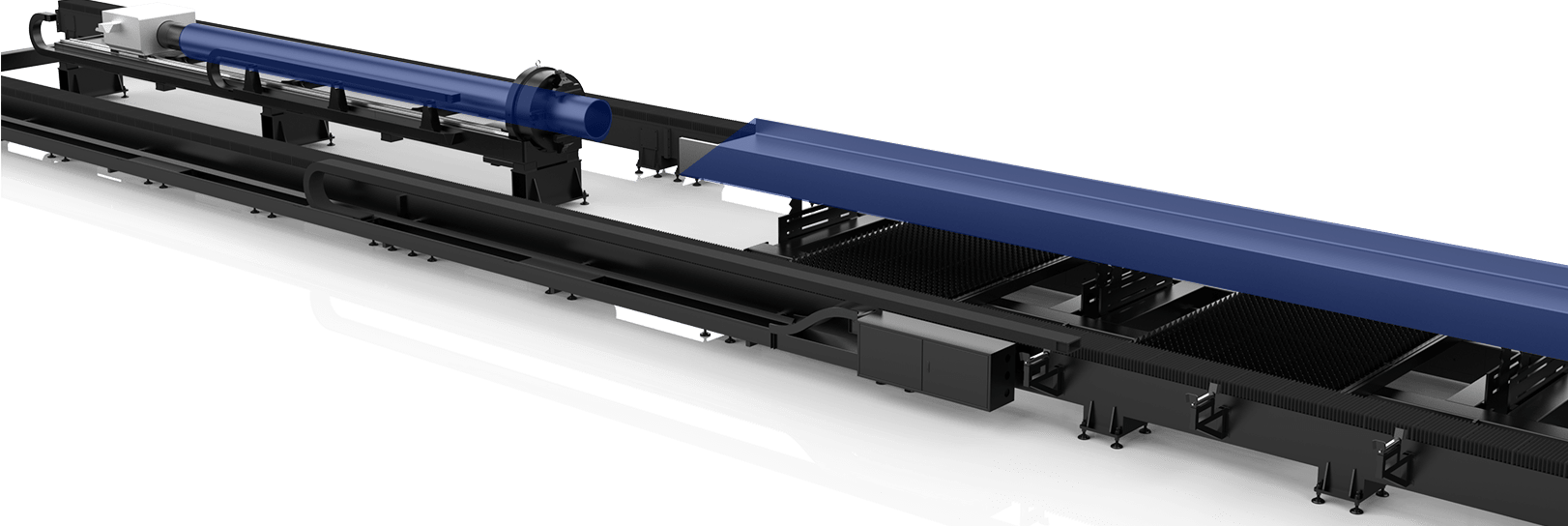

The platform carrying the laser cutting head moves along the length of the steel profile with a large range of motion, while the steel profile remains fixed. This supports contour detection, enabling processing such as cutting, drilling, chamfering, and arc cutting of H-beams, curved steel, and channel steel profiles. This platform can perform functions such as drilling, cutting, grooving, and marking on steel materials. It supports bevel grooving for various joint types and is compatible with cutting based on TEKLA / Solidworks 3D modeling data files. The dates generates G-code, enabling seamless integration from design to production, efficiently completing drawing and layout tasks and significantly shortening production preparation time. It also supports nesting and material optimization, achieving material utilization rates greater than 99%, and minimizing material waste through material splicing.

Features and Advantages

DW Series Cantilever-type Steel Laser Processing Center

The cantilevered open structure allows for convenient mechanical adjustment and easy material feeding; it utilizes a heavy-duty machine tool structure, with all functional components such as the laser and water chiller mounted on the moving platform, moving along with the cutting head. This effectively avoids energy loss caused by excessively long optical fibers, ensuring the stability and high efficiency of laser cutting; the dual-station design allows for simultaneous cutting at one station while the other station is used for lifting and loading/unloading, saving loading and unloading time and achieving continuous and efficient processing of structural steel; the processing is flexible, allowing for both segmented and full-length processing.

Processing Flow

DW Series Cantilever-type Steel Laser Processing Center

Manual crane material (two at a time) — Search alignment and profile detection (Station 1) — Cutting (Station 1) –Search alignment and profile detection (Station 2) — Cutting (Station 2) –Simultaneous manual loading and unloading (Station 1) –Round and round.

Heavy-duty Machine Cantilever Structure

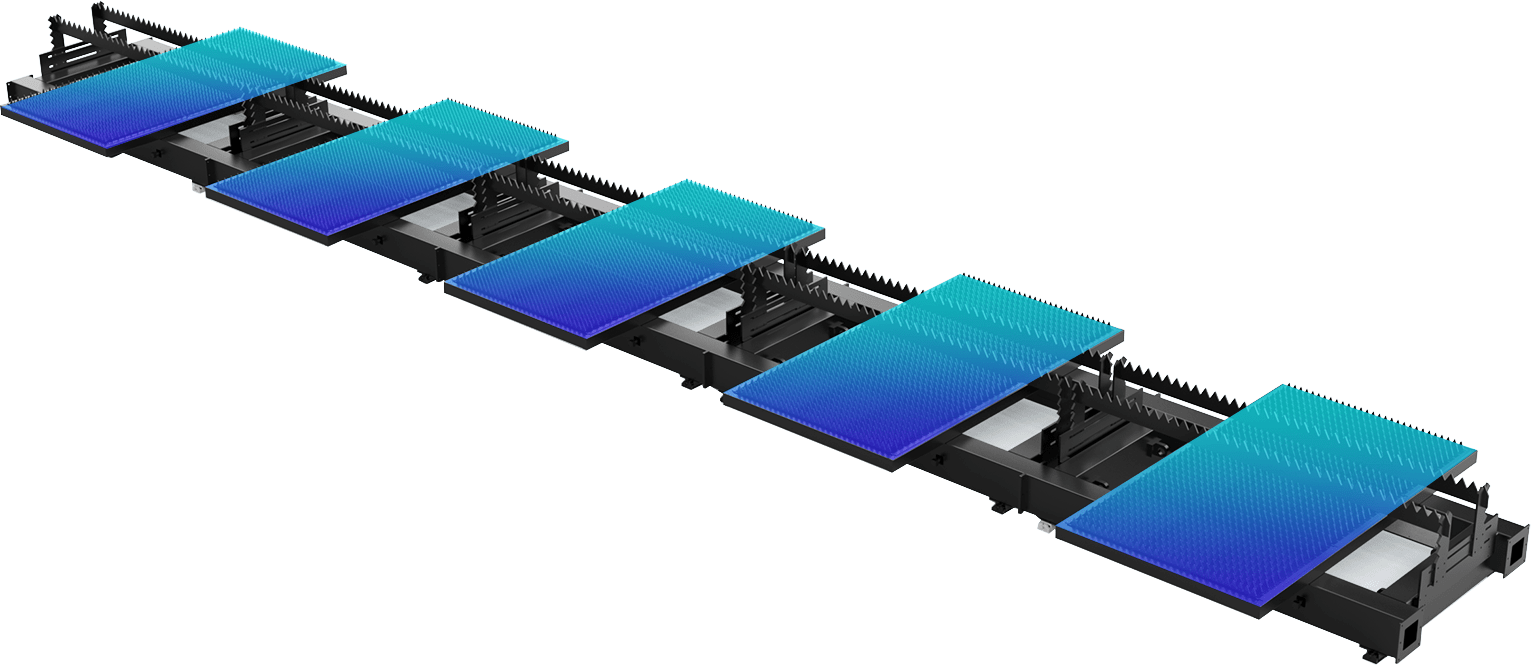

The Modular Heavy-duty Rail-type Bed Structure

The modular heavy-duty rail-type bed structure is the core cornerstone of Dowell Laser Cantilever-type Steel Section Laser Processing Center, designed to deliver unparalleled stability, durability and flexibility for high-intensity, high-precision metal processing scenarios—bringing tangible production value to your enterprise with hard-core structural advantages. Unlike ordinary lightweight bed structures that are prone to deformation and vibration during long-term operation, our modular heavy-duty rail-type bed is forged from high-quality thickened alloy steel, undergoing strict quenching and tempering heat treatment processes to eliminate internal stress, enhance structural rigidity and wear resistance, and ensure long-term dimensional stability even under 24-hour continuous high-load processing conditions. This robust structural design effectively suppresses vibration caused by high-power laser cutting and heavy-section steel loading, avoiding cutting errors and burrs, and laying a solid foundation for precise section steel beveling, flat plate beveling, square tube and round tube one-time forming processing.

Section Steel, Flat Plate, Square Tube &Round Tube Beveling

Equipped with high-end 5-axis CNC control system and high-power fiber laser, Dowell Laser Cantilever-type Steel Section Laser Processing Center breaks through the limitations of traditional separate processing, realizing one-stop one-time forming of section steel beveling (±45° adjustable), flat plate beveling, square tube and round tube cutting without repeated clamping or secondary processing. It integrates automatic feeding, precision positioning, intelligent beveling, high-precision cutting and automatic blanking into a seamless workflow, eliminating cumulative errors caused by multi-equipment turnover and ensuring that each workpiece has smooth bevel surfaces, neat pipe sections, no burrs or deformation. With a built-in professional cutting process database, the equipment can automatically match power, speed and air pressure parameters according to different materials and specifications, ensuring stable and consistent processing quality even in mass production. Suitable for steel structure, engineering machinery, bridge construction and other industries, it helps enterprises reduce labor input, shorten production cycle by 60% and improve material utilization rate to more than 99%, creating greater production value with hard-core technology.

Technical Parameter

Core technical parameters with high rigidity, high precision and high efficiency, covering laser power, processing range and dynamic performance, providing reliable data support for efficient and stable steel cutting.

|

Item.

|

Spec.

|

Item.

|

Spec.

|

|---|---|---|---|

|

The breadth of H-beam steel |

100mm~1000mm |

The height of H-beam steel |

100mm~500mm |

|

Cutting model |

Fiber laser cutting |

Workpiece length |

L≤12000mm, support customization |

|

Cutting form |

Fixed length straight out, fixed length oblique cut and end jack function |

Mainly applicable workpiece materials |

H/I beam structual carton steel, stainless steel |

|

Laser source |

Max 20000W(Optional) |

Cutting thickness |

Punch cutting 1mm~40mm |

|

Bevel cutting |

±45° |

X/Y axis postioning accutacy |

±0.10mm/m |

|

X/Y axis repeated positioning accuracy |

±0.05mm |

Max. speed of spaceflight |

X: 15m/min, Y/Z: 30m/min |

|

Max. weight of raw material |

5000kgs (Customer Requirements) |

The floor area of the entire equipment |

18000mm*6000mm*4500mm |

Main Equipment Configuration

Dowell Laser's cantilever-type steel laser cutting machine features core components from globally renowned brands, combining top-tier configurations to ensure high rigidity, precision, and stability. It is suitable for all heavy-duty steel structure processing applications, guaranteeing long-term efficient operation and providing a solid foundation for cost reduction and increased efficiency in production.

Item.

Brand/Model

Place of Origin

Laser steel cutting machine

Dowell Laser

Chine

Bearing table

Dowell Laser

Chine

Laser cutting head

EC+Ophit Black King Kong

Chine

Height regulator

WIS Cut

Germany

High precision gear reducer

MOTOVARIO

France

High precision diagonal rack

YYC

Taiwan, China

Linear guide

TBI/HIWIN

Taiwan, China

Fiber laser source

MAX

Chine

Main servo drive and motor

Inovance

Chine

Numerical control system

WIS Cut (Beckhoff)

Germany

Electronically controlled proportional valve

Aventics

Germany

Laser special water cooler

S&A

Chine

Regulated power supply

Domestic supporting facilities

Chine

Logiciel d'imbrication

WIS Cut (Beckhoff)

Germany

Technology Path of Steel Structure Processing

Intelligent and efficient processing technology path, integrating automatic feeding, precision positioning, laser cutting and blanking.

One clamping completes the whole processing flow, ensuring high efficiency, high precision and stable quality for section steel processing.

Industries

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradise

application

Construction

For beams and columns: H-shaped steel pipes are commonly used as floor joists and trusses in buildings, bridges and other structures. Can also be used as stair stringers and balustrades. These pipes can be cut to precise sizes and shapes, ensuring a strong and stable structure.

pont

H-shaped steel pipe laser cutting machines are also used in the bridge construction industry to cut various components, including:

Girder: H-shaped steel pipes are often used as girders for bridges. Laser cutters can cut these pipes to precise sizes and shapes, ensuring the bridge structure is strong and durable.

Trusses: H-shaped steel pipes can also be used as trusses in bridges.

Bridge railings: H-shaped steel pipes can also be used as bridge railings.

bateau

Hull: H-shaped steel pipes are commonly used as hull structural members

Deck and bulkhead: H-shaped steel pipes can also be used as decks and bulkheads of ships. These pipes can be cut to the precise lengths and angles required, ensuring a stable and compartmentalized ship structure.

Masts and booms: H-shaped steel pipes can also be used as masts and booms for ships.

industrie pétrochimique

Pipes: H-shaped steel pipes are commonly used as pipes in the petrochemical industry. Laser cutters can cut these pipes to precise sizes and shapes, ensuring leak-proof and safe transportation of fluids.

Pressure vessels: H-shaped steel pipes can also be used as pressure vessels in the petrochemical industry. Laser cutters can cut these pipes to precise sizes and shapes, ensuring the vessels are strong and durable enough to withstand high pressures.

Storage tanks: H-shaped steel pipes can also be used as storage tanks in the petrochemical industry. Laser cutters can cut these pipes to precise sizes and shapes, ensuring safe and reliable storage

Construction machinery

Mechanical rack: H-shaped steel pipes are often used as racks for various construction machinery. Laser cutters can cut these pipes to precise sizes and shapes, ensuring a strong and stable foundation for the machinery.

Booms and booms: H-shaped steel pipes can also be used as booms and booms for construction machinery. of booms and arms.

Supports and brackets: H-shaped steel pipes can also be used as supports and brackets for construction machinery.

All-in-one Laser Proceesing VS Traditional Processing

Dowell Laser H Beam Section Steel Laser Composite Processing Center has obvious and irreplaceable advantages compared with traditional steel section processing methods (flame cutting, plasma cutting, sawing, etc.), and the core differences are comprehensively compared as follows:

Comparison Item

Steel Section Laser Cutting

Traditional Processing

Required Equipment

Only one set structural steel laser cutting machine (a complete structural steel laser secondary processing line) to perform multiple processes: cutting, drilling, notching, welding hole creation, beveling, marking, scribing, etc.

Three-dimensional drilling machine, sawing machine, notching machine, beveling machine, plasma cutting machine, etc. (Manual assistance is still required for tasks such as powder coating and scribing.)

Labor Required

1-2 workers to load/unload materials and operate the machine.

5-6 workers to handle loading/unloading, material transfer, operating different machines, and manual marking/labeling.

Processing Efficiency

Average daily production (8 hours): 80-100 tons; approximately 4-5 times that of traditional methods.

Average daily production (8 hours): 20-30 tons.

Processing Accuracy

Using laser precision processing, the cutting accuracy is within 0.1mm; using laser line scanning measurement and compensation, a positioning error accuracy of 1-2mm is guaranteed;

Using the plasma cutting equipment has an accuracy of approximately 1mm, which is 10 times less precise than laser processing; manual marking with a tape measure has an accuracy error of 5-10mm.

Space Occupied

Linear dual-station system: approximately 2 * (2m * 13m) = 52m² (50-60m²)

The space occupied is approximately 2-3 times that of a steel profile cutting machine.

Material Transfer

Multiple processes completed in a single step, eliminating the need for material transfer.

Frequent transfers

Return on Investment

High initial investment, significant increase in yield; large initial investment, high later income.

Low initial investment, low yield; low initial investment, low later income.

Equipment Failure Rate

A machine that is mature in application, easy to operate, and has a low failure rate.

Drilling rigs, sawing machines, flame cutting, plasma cutting, and other various operations have multiple potential failure points; manual involvement makes it difficult to guarantee consistency.

Cost-effectiveness

Double the production capacity, smaller footprint, reduced labor costs, energy-efficient and environmentally friendly, and consistent quality; high long-term cost-effectiveness.

Low production capacity, large footprint, high labor costs, significant pollution, and inconsistent quality; low long-term cost-effectiveness.

Sécurité

True 3D five-axis machine tools ensure the laser always points to the material being processed, providing excellent safety! (Fake 3D five-axis machine tools have risks of laser divergence, uncontrollable direction, and unpredictable hazards); Easy operation, no need for material handling;

Multiple processes involve multiple risk points; repeated material handling increases the safety risks of manual operation.

Production Management

Secondary Processing Line: Automated production, processing task orders, production reports, work order reporting, MES system integration, production information management, complete set production.

Manual product inspection; document organization; manual data entry. Difficult to achieve digital and information-based management and complete set production.

Laser Bevel Cutting VS Traditional Bevel Cutting

Traditional bevel cutting methods rely heavily on manual labor, resulting in low efficiency and poor processing accuracy, as well as environmental problems such as noise and dust. In contrast, using Dowell laser bevel cutting technology, the dimensions are precise, the hole walls are smooth and perfectly vertical, mechanical marking is possible, and the process is clean and free of debris.

At the same time, when performing bevel cutting for processing, in order to ensure the strength of the weld, high requirements and high precision are needed for the bevel cut surface, and there should be no slag on the welding surface.

-

Manual Drilling

Inefficient, difficult to accurately position the holes, and requires frequent checking of drawings to determine the location.

-

Mechanical Drilling

Adds extra steps, repeated clamping is inefficient.

-

Plasma Cutting

Excessive heat concentration can easily lead to deformation of H-beams, resulting in excessively wide cuts and poor circularity.

FAQ

Quels sont les différents types de machines de découpe laser de tubes en acier H ?

- Machines de découpe laser fibre : Les machines de découpe laser à fibre sont le type le plus courant de machine de découpe laser de tuyaux en acier H. Ils sont connus pour leur efficacité, leur rapidité et leur capacité à couper une grande variété de matériaux.

- Machines de découpe laser CO2 : Les machines de découpe laser CO2 sont moins courantes que les machines de découpe laser fibre, mais elles sont toujours utilisées pour certaines applications. Ils sont connus pour leur capacité à couper des matériaux épais.

Combien coûte une machine de découpe laser de tuyaux en acier H ?

Le prix d'une machine de découpe laser de tubes en acier H peut varier en fonction de plusieurs facteurs, notamment la taille et la puissance du laser, la capacité de découpe de la machine et les fonctionnalités supplémentaires incluses. Cependant, en général, vous pouvez vous attendre à payer entre 85624,71 $ et 172630,46 $ US pour une machine de découpe laser de tuyaux en acier H.

Comment choisir une machine de découpe laser de tubes en acier H ?

Les facteurs suivants doivent être pris en compte quand Choisir une machine de découpe laser de tubes en acier H :

- La taille et l'épaisseur des tuyaux de poutre en H que vous devez couper

- Les types de coupes que vous devez effectuer

- Le niveau d’automatisation dont vous avez besoin

- Ton budget

les principaux fabricants de machines de découpe laser pour tuyaux en acier H ?

Certains des principaux fabricants des machines de découpe laser de tuyaux en acier H comprennent :

- Laser à chevilles (Chine)

- Groupe BLM (Italie)

- Bien-aimé (Japon)

- Le laser de Han (Chine)

- Mazak Opticics Corporation (États-Unis)