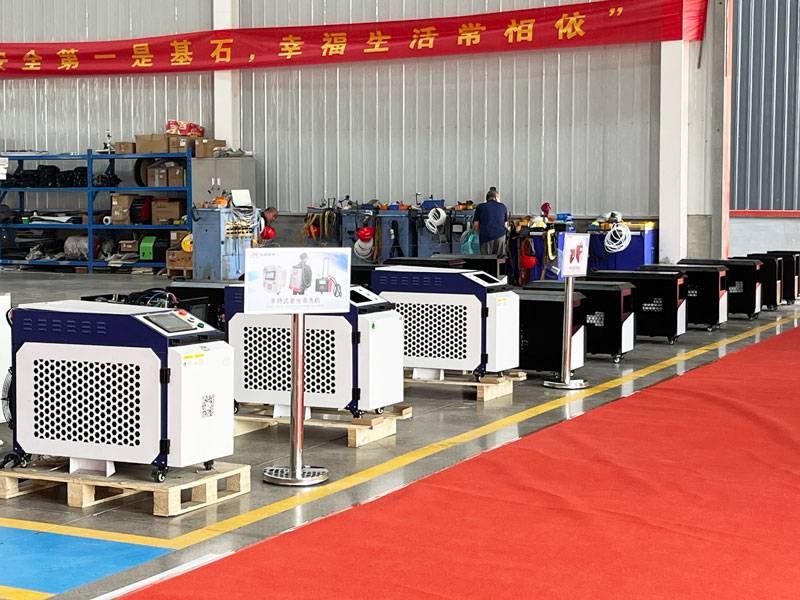

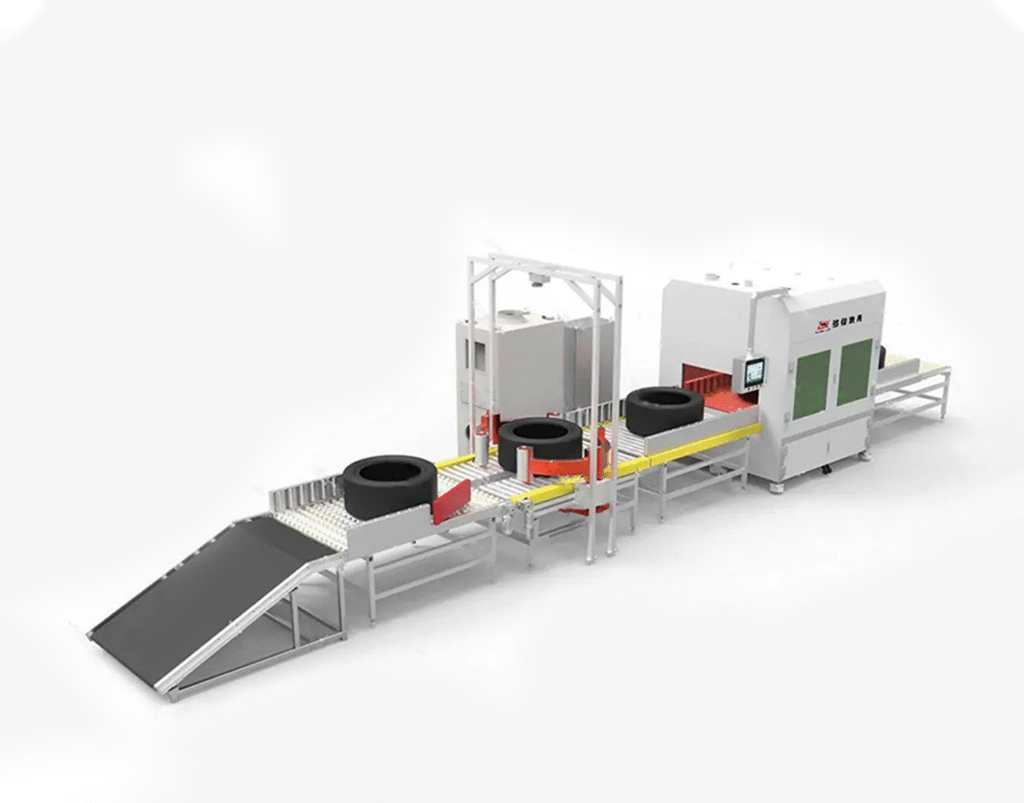

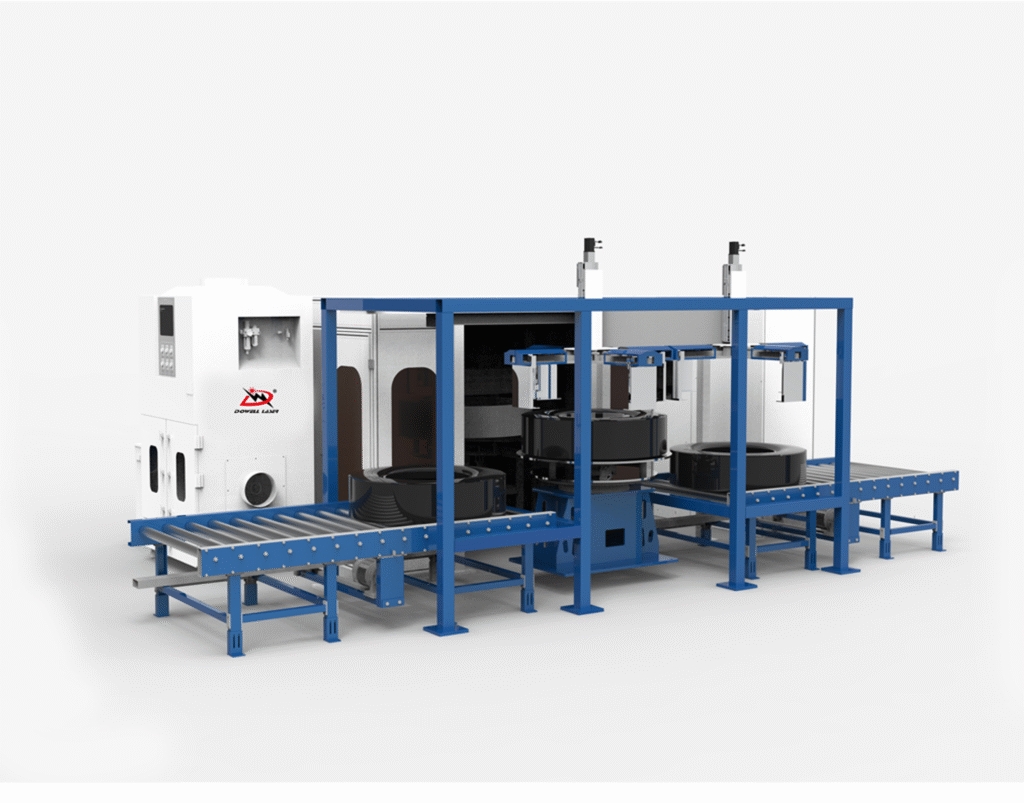

400mm Laser Cleaning Area

Ultra-wide Area of Fiber Laser Cleaning, which is much larger than the other supplier‘s standard.

Ultra-wide Laser Cleaning Area

On average counting, the fiber laser cleaning range has increased by about 130% compared to other suppliers.

7*24 Hours Continuous Laser Cleaning

It can operate continuously for 7*24 hours without burning out the fiber laser cleaning lenses.

Improved Laser Cleaning Efficiency

According to the actual operation calculation of end users, the cleaning efficiency using Dowell Laser will be effectively improved by 37% to 69%.