With the rapid development of laser technology, more and more materials can be cut, from metal, non-metal, wood, etc., bringing infinite possibilities to people’s lives. I will take you to understand “what materials can a laser cutter cut”.

What Materials Can a Laser Cutter Cut

- Wood

- Acrylic

- Plywood

- MDF (Medium-density fiberboard)

- Cardboard

- Paper

- Fabric

- Leather

- Glass (with specialized laser cutters)

- Foam

- Rubber

- Metal sheet

Several kinds of plastics Several factors such as material composition and thickness determine if a particular material is suitable for laser cutting. During laser cutting, some materials may produce harmful gases and fumes; hence, having well-ventilated zones and safety measures is important.

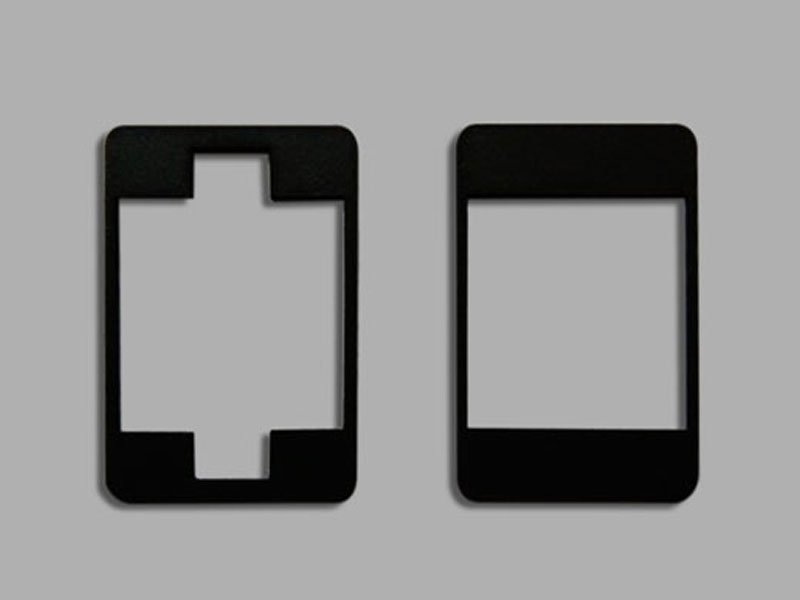

Laser cutting Metal: Cutting Through Steel, Aluminum, and More

Metal laser cutting technology is usually used frequently in cutting metals, such as steel plates, aluminum plates, brass, etc. The metal fiber laser cutting system cuts these metal materials with ultra-high cutting accuracy, achieving fast and efficient results.

Steel is known for its strength and durability in the automotive and construction industries. Metal laser cutting equipment can simply cut complex graphics on steel plates, improving the manufacturer’s production efficiency. Laser-cut metal art is used in home design, metal murals, metal panels, fence panels, and more.

Laser cutters can also work with other metals such as brass, copper, and titanium. These materials pose challenges to laser technology due to their unique nature. Through precise calibration and adjustment of laser power settings, these metals can be conquered by the powerful beam of the laser.

Laser Cutting Wood: Plywood, MDF, and Beyond

Wood is a very common material among artisans. Quand wood is cut through laser, it can make their design better, achieve graphics that are hard to cut, and assist in carving various patterns.

Laser beams cut most medium density fiberboard (MDF). This means that the strong structural capabilities of MDF can be maintained even during complex cutting. Laser-cut wood encompasses a variety of wooden products such as tables with delicate patterns or fragile decorative items.

Birch, cherry, and walnut are some examples of woods suitable for laser cutting. Each type has its unique beauty and characteristics which makes it possible for designers to create one-of-a-kind pieces that reflect the inherent attractiveness of material.

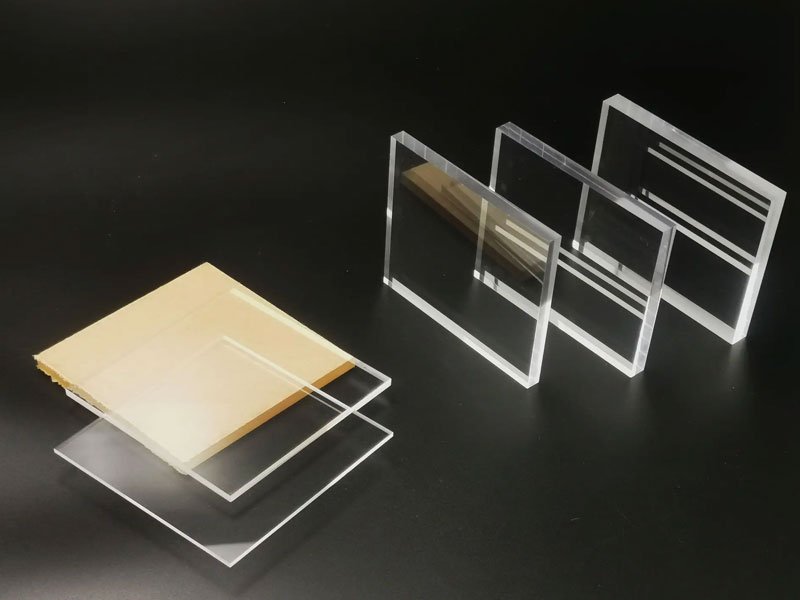

Laser Cutting Acrylic: Transparent Beauty in Precision Cuts

The glass-like finish and the versatility of acrylic make it a preferred material for artists and designers. One of the best ways to shape intricate patterns on acrylic sheets while leaving the edges very clean is by laser cutting. The melting that occurs during laser cutting of acrylic causes the resulting surface to be smooth, hence requiring minimal post-processing.

Different products such as personalized signage and exquisite jewelry can be made from acrylic using laser cutting technology; this kind of plasticity makes it easy to play with light to create amazing shadow effects that stand out, the reason why it is commonly used in decorative objects or architectural modeling.

Laser Cutting Fabric: From Silk to Leather

The textile industry has been transformed by laser cutters, which allow for exact cutting solutions in different fabrics. Silk and lace are some of the fragile materials that can be easily shaped into complicated patterns without getting damaged. As such, fashion designers can explore new avenues of originality by going beyond known limits in designing clothes.

Leather is yet another fabric that laser cutting works well with. This enables it to provide clear impressions on leather goods like bags, shoes, and accessories. It is now possible to draw detailed designs on a surface or even remove them completely because the beam’s concentration makes such processes simple.

Laser Cutting Paper: Intricate Designs with Ease

Paper is a relatively breakable material compared to other materials used for cutting, but the use of laser cutters can easily overcome this challenge. From wedding invitations to the most detailed paper art, laser cutting simplifies intricate handiwork. Cutting is accurate without breaking or spoiling them.

Different kinds of paper such as cardboard, vellum, and even thin pieces of wood can be used by artists and designers. The possibility to make complex designs and patterns gives an unlimited chance of coming up with amazing things using paper.

Laser Cutting Glass: Precision without Shattering

Glass is fragile. Using a laser cutting machine can finely engrave and cut the surface of the glass without damaging it, making it possible to make complex designs on glassware or decorative glass panels.

The heat generated by the laser beam can produce tiny cracks on the glass surface, allowing precise control to achieve complex pattern cutting. Laser cutting can be easily achieved whether it is on glass wine glasses or colored glass.

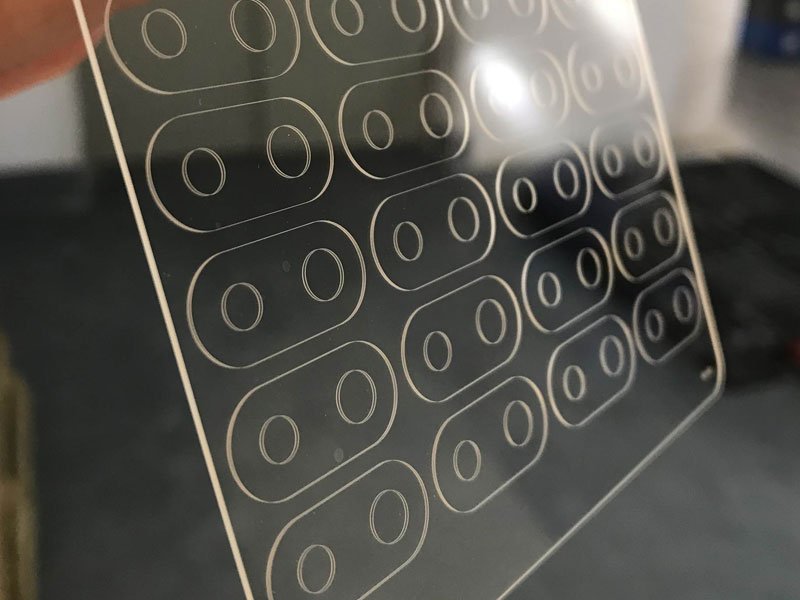

Laser Cutting Plastics: ABS, Polycarbonate, and More

The laser cutting machine should have different settings for each type and format of plastic. ABS is the most common type of thermoplastic used in laser cutting process applications. This material is widely employed in prototyping and manufacturing as it is durable and versatile.

Polycarbonate is a plastic that can be easily shaped using a laser cutter. It can be used to produce safety goggles or machine guards because it has high impact strength. Moreover, other types of plastics like acrylic are considered to fit into this category as they possess properties similar to what was discussed above.

Laser Cutting Stone and Concrete: The Solid Cuts of Laser Technology

Since stone and concrete appear as insurmountable materials to slice through, one may assume that they are not easy to cut. However, this has been made achievable by laser technology as now we can mold these hard bodies with great accuracy. That is why starting from architectural pieces to the most intricate of sculptures, a laser cutter will always find its way into engraved designs on granite surfaces.

The immense power of the beam enables materials to be removed in a controlled manner leading to clean cuts and detailed engravings. As a result, artists and designers are encouraged to think about combining traditional materials with modern technologies.

Laser Cutting Ceramics: Precision in Delicate Designs

Due to their fragility, Ceramics demand a careful attitude while laser cutting. With the right settings and expertise, ceramic surfaces can be etched or cut by a laser cutter without causing cracks or damage.

This opens up avenues for creating intricate tiles, decorative pottery and even personalized ceramic gifts. Laser cutting technology offers precision that enables fine detailing to be done on these brittle materials.

Conclusion:

As we end our journey into the world of laser cutting, one thing becomes abundantly clear – the possibilities are truly endless.

Laser cutting technology has made our lives more possible, from metals to fabrics, plastics to ceramics. Laser cutting machines have proven their versatility, allowing them to precisely and finely shape a wide range of materials.

Whether you’re a designer pushing the boundaries of creativity or an industry professional looking for efficient manufacturing solutions, a laser cutter can be your ultimate ally. You find yourself asking “what materials can a laser cutter cut?” Remember, the answer lies in your imagination and the limitless capabilities of this remarkable technology.